Book cooling and forming mechanism for full-automatic glue binder

A technology of cooling molding and glue binding machine, which is applied in the direction of binders for binding, book binding, and the compound continuous process of book processing, etc. It can solve the problems of lower book yield, hollowed out spine of finished books, and easy glue leakage, etc. Achieve the effect of high degree of automation, good molding, and avoid glue leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

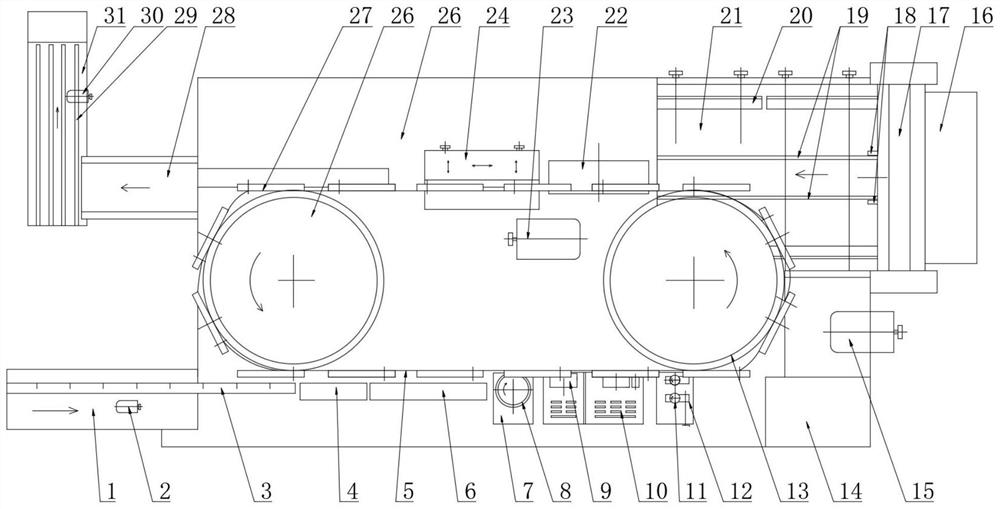

[0028] see figure 1 , the present invention discloses a fully automatic glue binding machine, comprising a book clip transmission assembly 100, a book block alignment mechanism 200, a gluing mechanism 300, a sealing mechanism 400, a sealing mechanism 500, a book wrapping forming mechanism 600 and a power transmission system 700;

[0029] Specifically, the book folder transmission assembly 100 is arranged in the center of the glue binding machine platform 25, and includes a large driving chain plate 26 that is rotated on one side of the glue binding machine platform. The large driven chain disc 13 on the other side of the platform is connected by transmission. The book holder drive chain 5 is fixedly provided with several book holders 27 for holding book blocks. The transmission chain 5 moves forward, and the spine of the book block is perpendicular to the glue binding machine platform 25 downward; Disc 26 and large driven chain disc 13 form a runway-shaped track, and the boo...

Embodiment 2

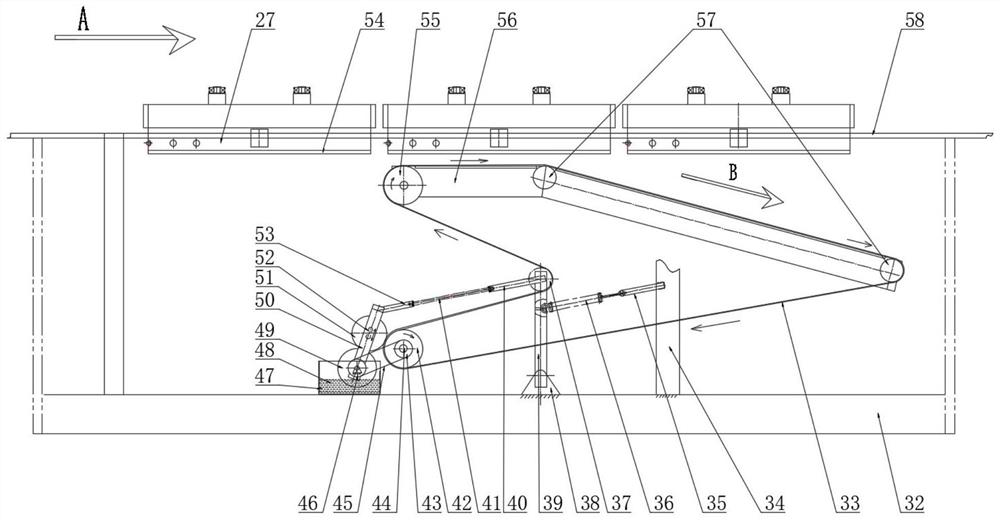

[0039] refer to figure 2 , the present invention is used for the booklet cooling and forming mechanism of the automatic glue binding machine, the book cooling and forming mechanism 900 is set in conjunction with the book folder transmission assembly 100 of the automatic glue binding machine, and is also equipped with a power transmission system in cooperation with the book folder transmission assembly 100 700; the power transmission system 700 is used to drive the operation of the book folder transmission assembly 100; in this embodiment, the booklet cooling forming mechanism 900 belongs to a part of the book wrapping forming mechanism 600 of the automatic glue binding machine, and is mainly used for the completed gluing The spine of the enclosed booklet is smoothed and cooled.

[0040] Wherein, the book folder transmission assembly 100 includes a large driving chain plate 26 and a large driven chain plate 13 which are arranged to rotate along the horizontal plane of the bind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com