A kind of preparation method of plugging mud ball suitable for industrial silicon smelting to produce silicon

An industrial silicon and hole-blocking technology, which is applied in the direction of chemical instruments and methods, applications, silicon compounds, etc., can solve problems such as leakage, secondary pollution of products, and product degradation, so as to avoid secondary pollution and reduce the rate of impurities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and embodiments.

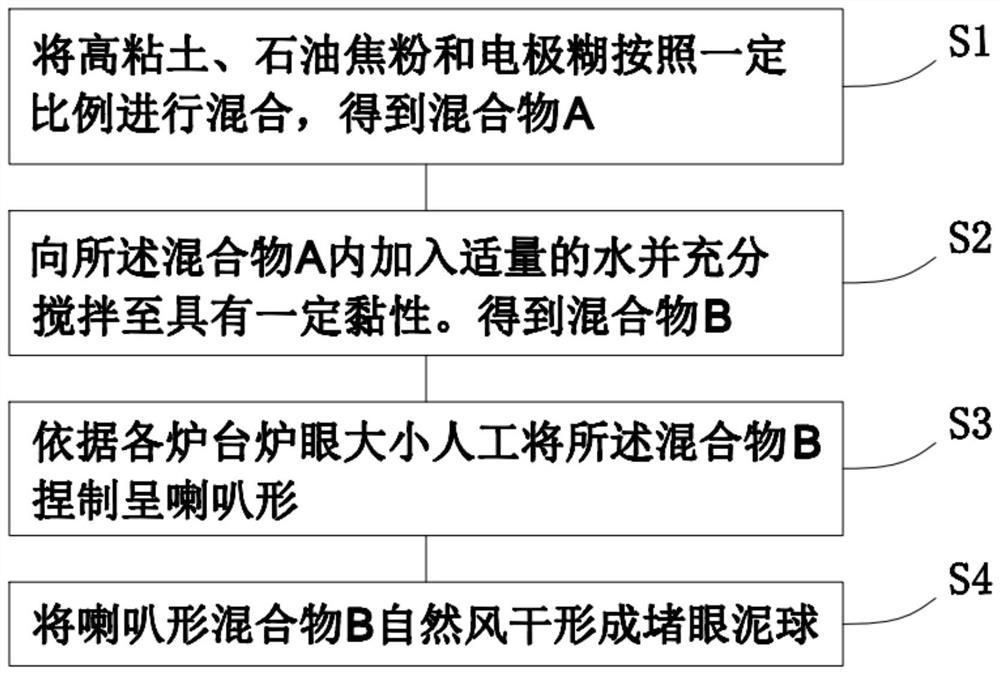

[0020] Please refer to figure 1 , figure 1 The present invention is a flow chart of a preferred embodiment of the method for preparing eye-plugging mud balls for industrial silicon smelting. A method for preparing eye-blocking mud balls suitable for industrial silicon smelting to produce silicon comprises the following steps:

[0021] S1: Mix high clay, petroleum coke powder and electrode paste in a certain proportion to obtain mixture A;

[0022] S2: Add an appropriate amount of water to the mixture A and stir well until it has a certain viscosity. to obtain mixture B;

[0023] S3: manually kneading the mixture B into a trumpet shape according to the size of the hearth of each furnace;

[0024] S4: The trumpet-shaped mixture B is naturally air-dried to form an eye-plugging mud ball.

[0025] In the step S1, the ratio of high clay, petroleum coke po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com