A hydrogenation method and system for producing chemical materials

A chemical industry and hydrogenation reaction technology, applied in the field of hydrocarbon oil cracking, can solve the problems of low yield of heavy naphtha fraction, low aromatic content and lower tail oil quality, and improve the quality of hydrogenated wax oil fraction and aromatic content High, high hydrogen content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

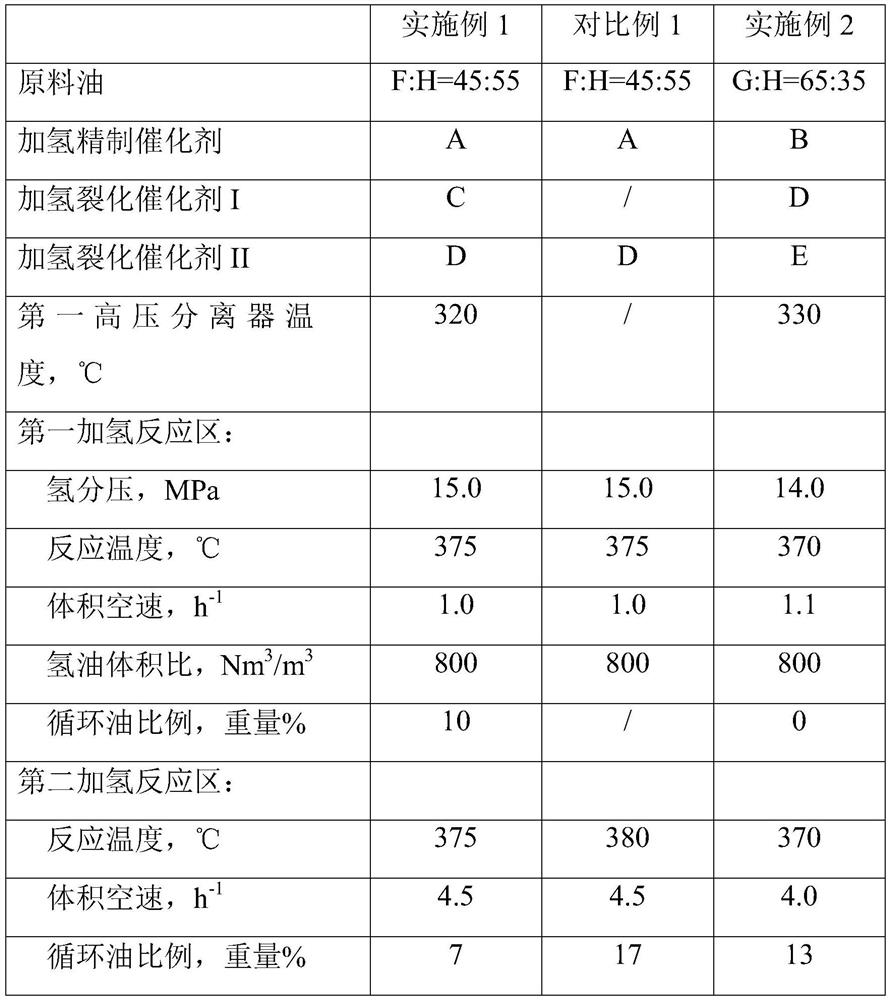

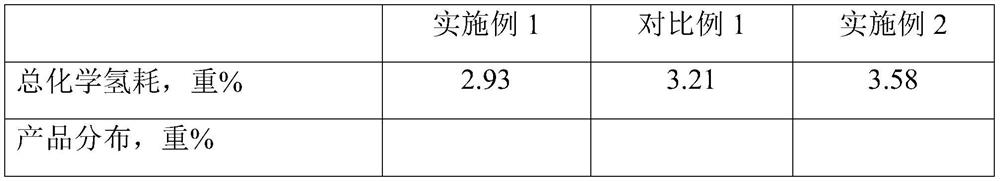

Embodiment 1

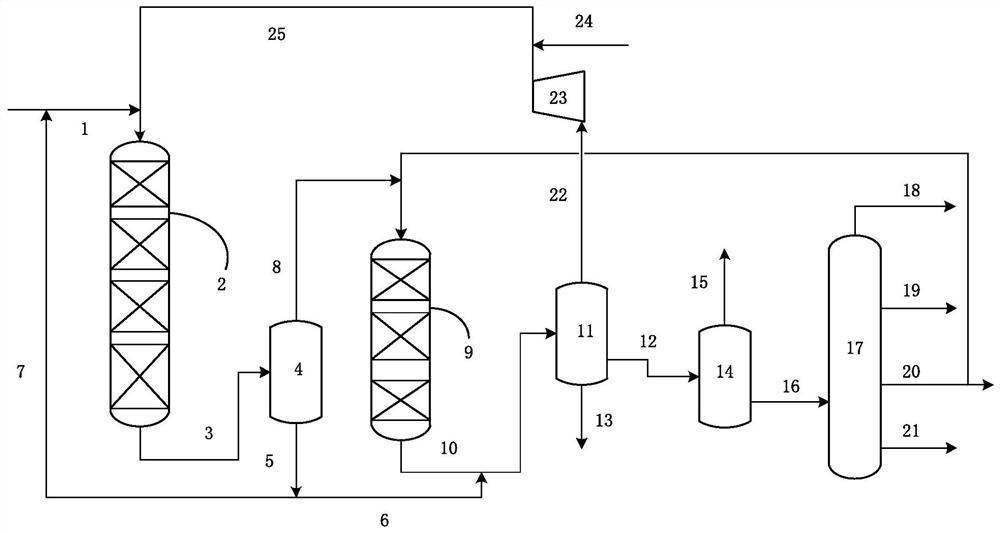

[0048] The mixed raw material of the raw material oil E and the raw oil G enters the first hydrogenation reaction zone together with hydrogen, sequentially contact with the hydrothermal catalyst A and hydrocracking catalyst C, and its reaction effluent enters the first high pressure separator for gas Separation, the first liquid phase stream part circulates back to the first hydrogenation reaction zone to mix the feedstock as a fresh raw material, the circulating first liquid phase stream is 10% by weight of the fresh raw material, the remainder of the first liquid phase logistics enters the first Two high pressure separators. The resulting first gas phase stream enters the second hydrogenation reaction zone equipped with a hydrocracking catalyst D, and the reaction effluent enters the second high pressure separator for gas-liquid separation, separating the obtained second liquid phase stream into the fractionation column, diacedent The light stone brain distraction, heavy stone b...

Embodiment 2

[0052] The mixed raw material of the raw material oil F and the raw material oil G enters the first hydrogenation reaction zone together with hydrogen, sequentially contact with the hydrothermal catalyst B and the hydrocracking catalyst C, and the reaction effluent enters the first high pressure separator for gas The liquid is separated, and the resulting portion of the first liquid phase stream is isolated into the second high pressure separator. The resulting first gas phase stream enters the second hydrogenation reaction zone equipped with a hydrocracking catalyst D, and the reaction effluent enters the second high pressure separator for gas-liquid separation, separating the obtained second liquid phase stream into the fractionation column, diacedent The light stone brain distraction, heavy stone brain distraction, diesel fraction and tail oil fraction are obtained, and the diesel fraction returns to the second hydrogenation reaction zone for recycling, and the circulating dies...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com