Production method of 250 MPa-grade high-strength interstitial-free steel

A technology of interstitial atom-free steel and production method, which can be applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problem of high production cost, and achieve the effect of high strength and excellent stamping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

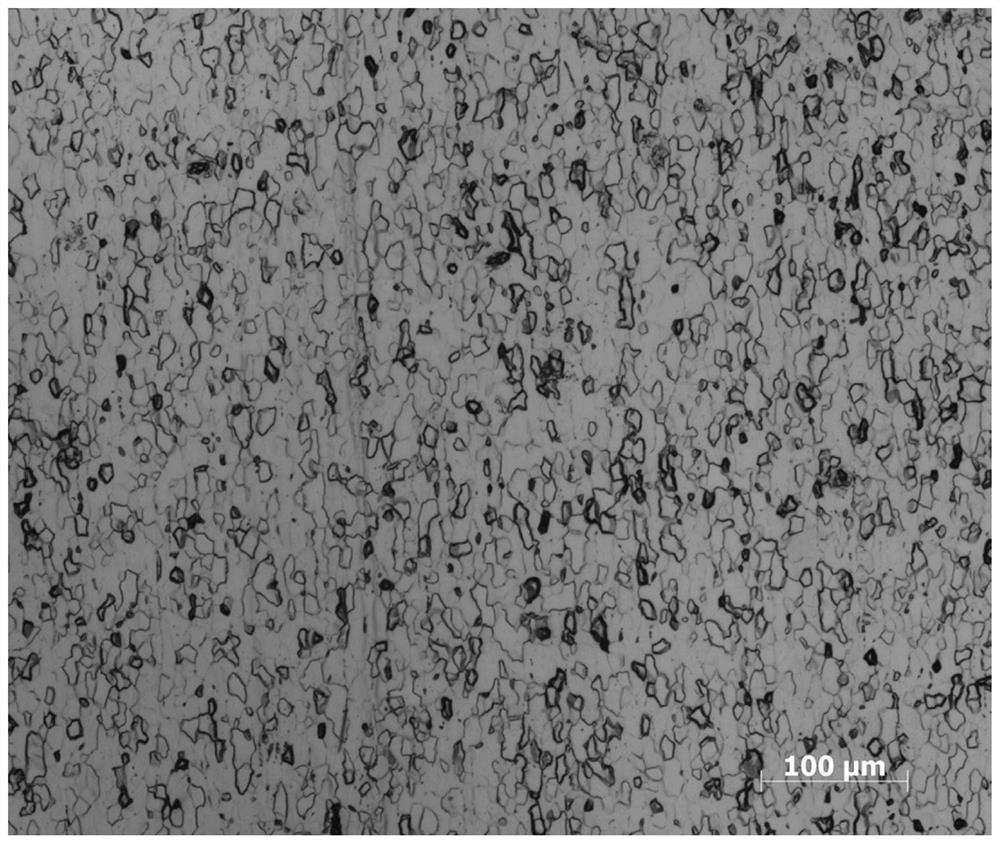

Image

Examples

Embodiment Construction

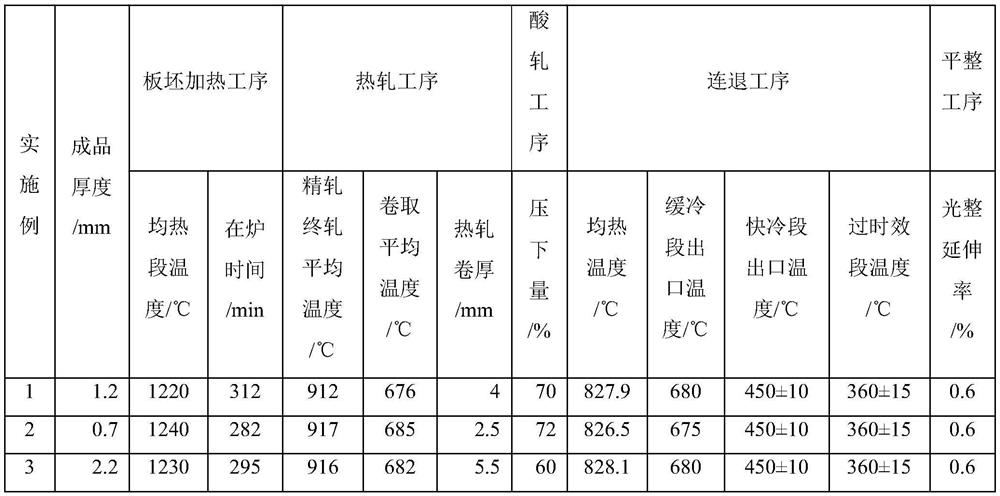

[0018] The following are specific examples of the present invention, further describing the technical solutions of the present invention, but the protection scope of the present invention is not limited to these examples. All changes or equivalent substitutions that do not depart from the concept of the present invention are included in the protection scope of the present invention.

[0019] A production method of 250MPa high-strength interstitial-free steel, using a low-carbon, low-silicon, high-phosphorus-manganese, Nb+Ti composite composition system, the chemical composition weight percentage is: C: ≤ 0.005%, Si: 0.08% ~ 0.12 %, Mn: 1.5% to 2.0%, P: 0.06% to 0.10%, S: ≤0.010%, Ti: 0.02% to 0.05%, Nb: 0.02% to 0.04%, B: 0.0005% to 0.0020%, Als: 0.02%~0.060%, N: ≤0.0040%, the rest is Fe and unavoidable impurities.

[0020] The production method of 250MPa grade high-strength interstitial-free steel, the specific steps are as follows:

[0021] 1) Slab heating process: the sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com