Fixed-rotation-center type multi-axis full-flexible hinge of series structure

A technology of rotation center and series structure, applied in the direction of pivot connection, etc., can solve the problems of unstable rotation center and difficult processing, and achieve the effect of large movement space range, small size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

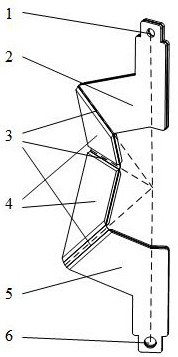

[0018] This example figure 1 As shown, the multi-axis fully flexible hinge with a fixed rotation center in series structure includes an upper connection part (2), two middle connection parts (4) and a lower connection part (5) sequentially connected in series with three flexible hinges (3). The upper connecting part (2) and the lower connecting part (5) have upper connecting holes (1) and lower connecting holes (6) conveniently connected with other mechanisms. The upper connection part (2), the middle connection part (4) and the lower connection part (5) are all three-layer composite structures, including two upper and lower hard plates, and a flexible film in the middle. The three flexible hinges (3) are obtained by cutting a long strip at the same position on the front and back of the composite board between the two connecting parts, exposing the flexible film in the middle, and forming a long thin-walled structure penetrating at both ends, so that the flexible hinge The co...

Embodiment 2

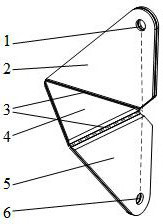

[0020] This example figure 2 As shown, the multi-axis fully flexible hinge with a fixed rotation center in series structure includes an upper connection part (2), a middle connection part (4) and a lower connection part (5) connected in series with two flexible hinges (3). (2) and the lower connecting part (5) have an upper connecting hole (1) and a lower connecting hole (6) conveniently connected with other mechanisms. The middle connecting part (4), the upper connecting part (2) and the lower connecting part (5) are all three-layer composite structures, including two upper and lower hard boards, and a flexible film in the middle. The two flexible hinges (3) are obtained by cutting a long strip at the same position on the front and back of the composite board between the two connecting parts, exposing the flexible film in the middle, and forming a long thin-walled structure that runs through both ends, so that the flexible hinge The connecting parts on both sides can perfor...

Embodiment 3

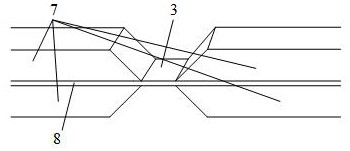

[0023] This example Figure 4 As shown, the fixed rotation center multi-axis fully flexible hinge of the series structure is a whole, and the flexible hinge (3) is formed by directly processing three long grooves on the plate material, and the rotation of the three flexible hinges (3) The axes intersect at a point in space, and the intersecting point in space is the fixed rotation center of the multi-axis fully flexible hinge. The fixed center of rotation multi-axis fully flexible hinge of this series structure can act as a spherical hinge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com