Fuel gas conveying pipeline

A technology for transporting pipelines and gas, which is used in pipeline protection, pipeline damage/wear prevention, pipeline anticorrosion/rust protection, etc. It can solve the problem that pipelines are easily corroded by organic substances, reduce the gas transmission efficiency in pipelines, and shorten pipeline service life. and other problems to achieve the effect of reducing the risk of aging, improving the service life and improving the pressure bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

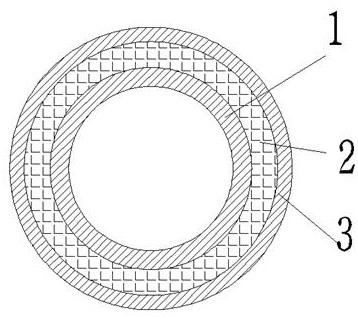

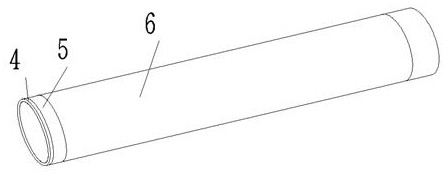

[0020] As shown in the drawings: a gas delivery pipeline, including an inner layer 1, an intermediate layer 2 and an outer layer 3, the inner layer 1 is a waterproof and anti-oxidation pipe blank metal layer, the middle layer 2 is a PET insulation layer, and the insulation layer includes an inner layer PET layer, insulation layer and outer PET layer, the outer layer 3 is an alloy layer, and the thickness of the gas pipeline 6 is 0.5-4cm. Preferably, the thickness of the gas pipeline 6 is 1-3 cm; more preferably, the thickness of the gas pipeline 6 is 0.6 / 1.5 / 2 / 2.2 cm; it is convenient to improve the structural strength and pressure bearing capacity of the gas pipeline 6 .

[0021] In the embodiment, the two ends of the gas delivery pipeline are connected by the annular connecting piece 4 and fixed by welding. It is convenient to improve the structural strength of the gas pipeline, and at the same time prevent the outer layer 3 of the gas pipeline 6 from loosening or falling of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap