Agricultural forage chopping treatment device

A technology for processing devices and forages, applied in the agricultural field, can solve the problems of lack of clamping equipment, tool stoppage, equipment damage, etc., and achieve the effects of reducing cleaning workload, ensuring space utilization, and improving material discharge efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

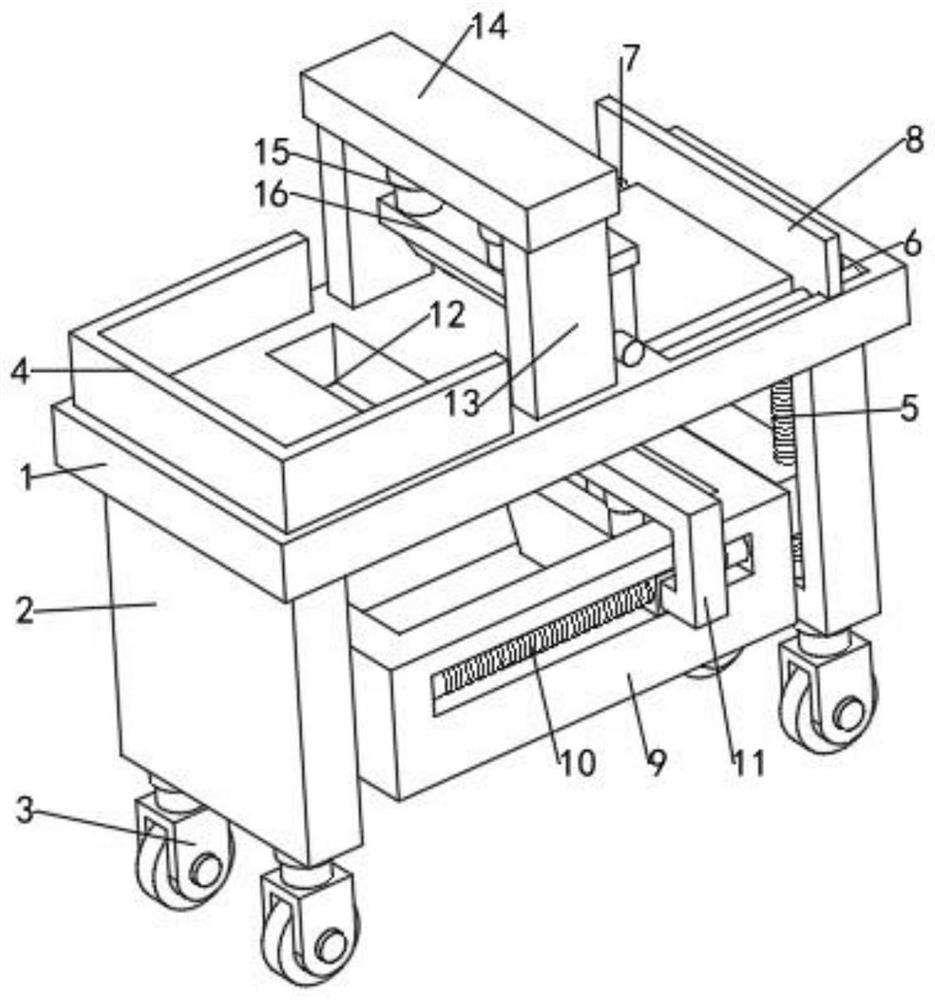

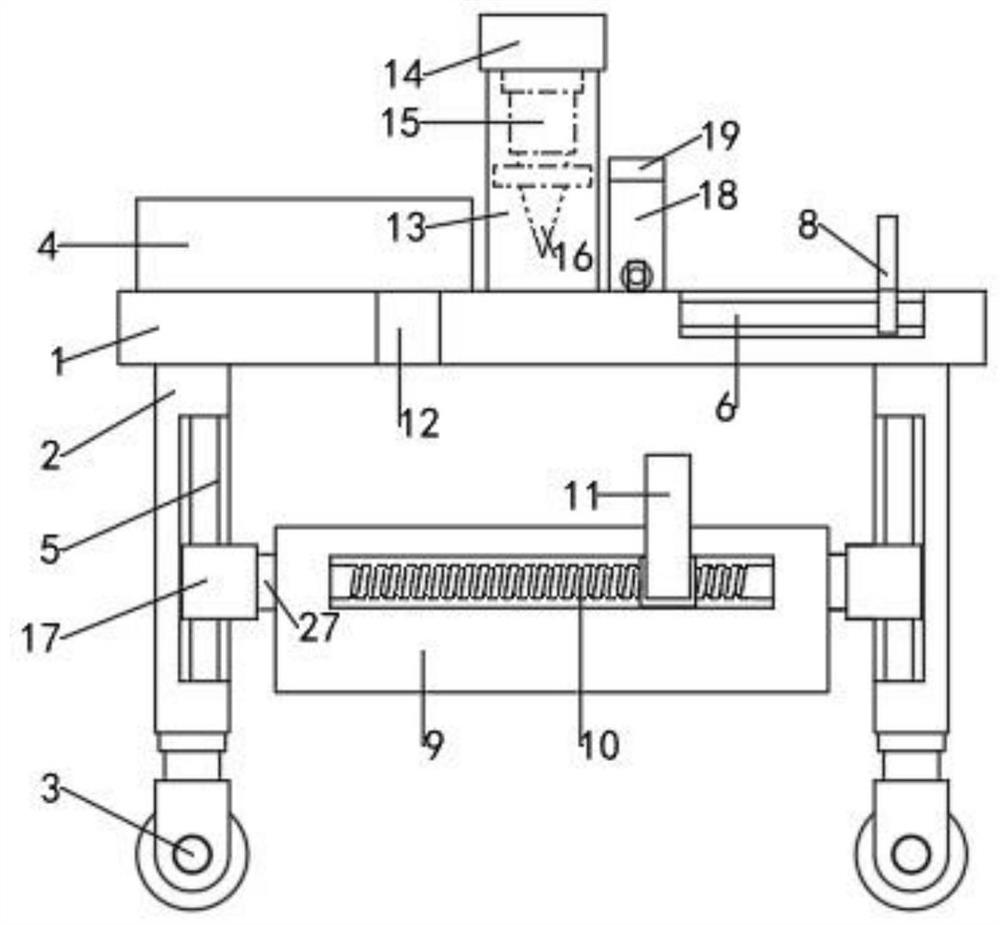

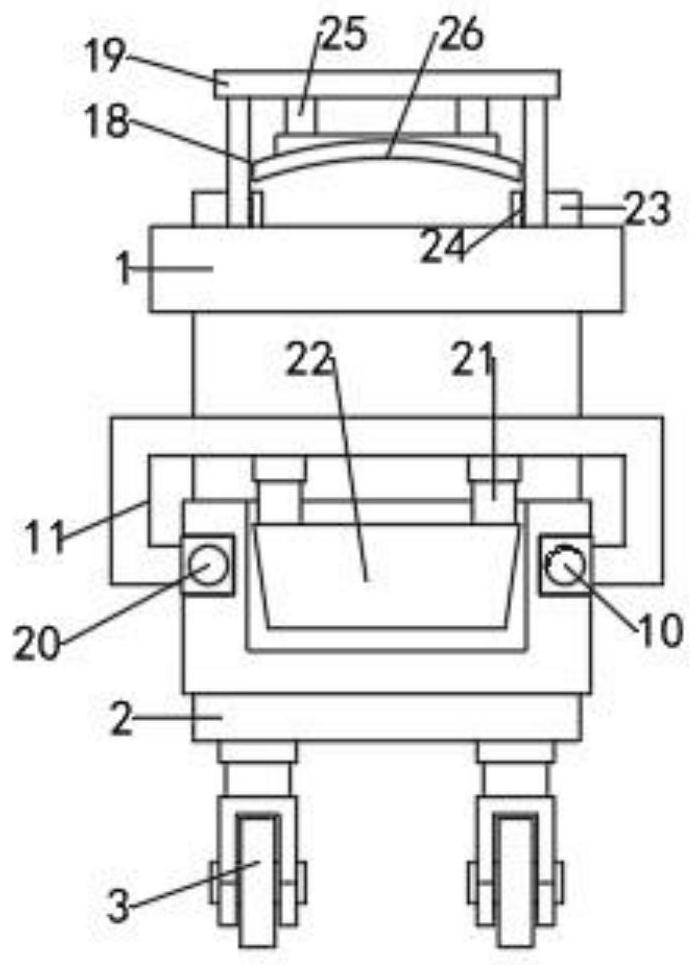

[0020] see Figure 1-4 , an agricultural forage chopping processing device, comprising a workbench 1, the lower end of the workbench 1 is fixedly connected with two substrates 2 arranged at intervals, and a collection bin 9 is assembled between the two substrates 2; the workbench The upper end surface of 1 is provided with a pushing mechanism, a clamping mechanism and a cutting mechanism in sequence, and the upper end of the workbench 1 is provided with a through discharge chute 12, and the discharge chute 12 is located on the side of the cutting mechanism away from the clamping mechanism; The material mechanism includes a vertical pusher plate 8, and the workbench 1 is provided with two non-through grooves spaced apart, and the workbench 1 is equipped with a horizontal transmission rod 6 and a feed screw 7 through the groove, and the feed wire One end of the rod 7 extends to the inside of the workbench 1 and is connected with a motor in transmission. A pusher plate 8 is insta...

Embodiment 2

[0029] In order to prevent the fodder from falling on the workbench 1 after it is chopped, so as to increase the subsequent cleaning intensity, this embodiment is improved on the basis of embodiment 1. The improvement is: the upper end surface of the workbench 1 is fixed A baffle 4 is connected, and the baffle 4 is located on the side of the discharge trough 12 away from the support plate 13. The cross section of the baffle 4 is concave, so that forage will not fall to the ground through the workbench 1, reducing the difficulty of subsequent cleaning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com