Shrimp peeling method of an automatic shrimp peeling machine

A shrimp peeling, automatic technology, applied in shrimp/lobster processing, slaughtering, food science and other directions, can solve the problem of low processing efficiency of processed shrimp products, a lot of downtime and time to adjust equipment, shrimp food hygiene problems are not effectively guaranteed, etc. problems, to achieve the effect of increasing labor costs and labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

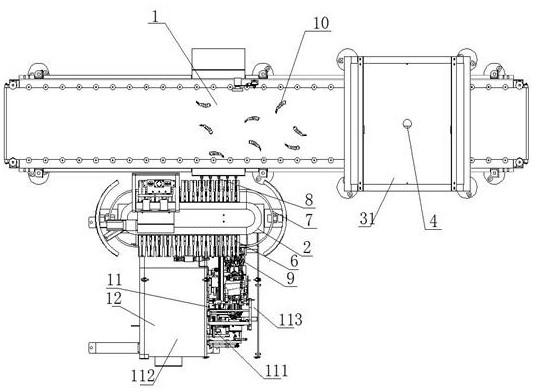

[0109] As another preferred embodiment of the present application, this embodiment provides a shrimp peeling method for an automatic shrimp peeling machine. The shrimp peeling method for an automatic shrimp peeling machine provided by this embodiment can effectively solve the problems in the above-mentioned prior art. On this basis, it can further solve the problems of low efficiency of shrimp feeding and the lack of effective protection of shrimp food hygiene problems caused by the manual feeding of existing shrimp peeling machines; The problem of inaccurate positioning of shrimps caused by shrimps. It also solves the problems of long downtime and slow adjustment efficiency in the prior art when changing the specifications of shrimp products.

[0110] The basis for the improvement of this technical solution is: the existing ones are placed manually, and there is a positioning line in the shrimp storage tank in the prior art. If it is placed in alignment with the positioning ...

specific Embodiment approach

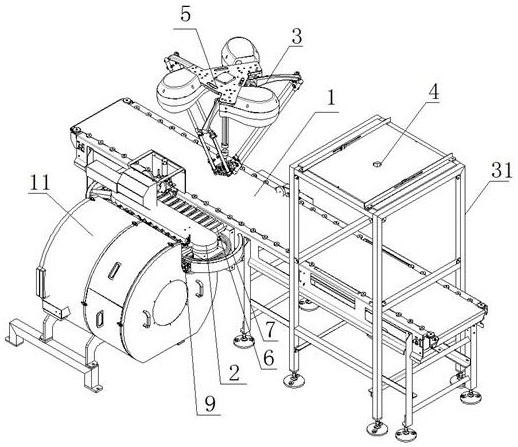

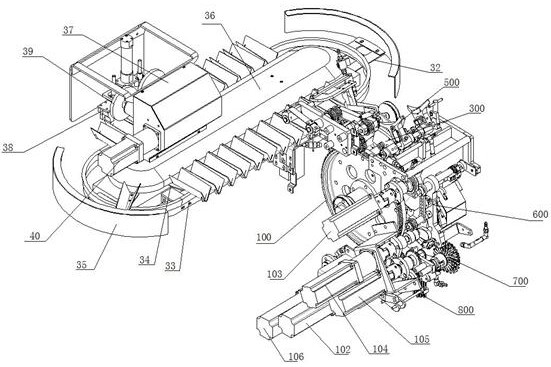

[0134] As a preferred embodiment of the present application, this embodiment provides an automatic shrimp peeling machine. The purpose of the invention of this technical solution is to solve the complex transmission structure, difficult adjustment, and inability to customize the menu to process shrimp products in the prior art. , unable to meet the diverse needs of the market. In this embodiment, the transmission parts between each component and the main transmission gear are specifically omitted, and a separate servo motor is connected to the main transmission gear, the conveying device, the blade assembly, the intestinal removal brush, and the long needle insertion assembly. The servo motor action of the above components is controlled by the control unit as a whole to form a whole device, so that the speed of the drive servo of each component can be matched, and the individual components can be adjusted at the same time, the adjustment is fast and convenient, and it can also ...

Embodiment 3

[0156] As another preferred embodiment of the present application, this embodiment is a further improvement made on the basis of embodiment 1 and elaborated in detail.

[0157] For the shrimp peeling machines currently on the market, refer to the instructions attached Figure 17 , whether it is the shrimp peeling machine designed by the American Jonsson company or the shrimp peeling machine improved by the Chinese company, the shrimps are sorted manually, and after sorting, they are neatly arranged in the shrimp tank of the feeding tray (conveying device). Complete automatic shrimp peeling cannot be realized at all, and it only belongs to semi-automatic shrimp peeling. This shrimp peeling machine can only complete the work of peeling shrimp meat, but the feeding of raw shrimp still needs to be done manually. Since the feeding and arranging of the raw shrimp are done manually, the processing efficiency cannot be effectively improved, and the manual discharge method is also not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com