Titanate chelating agent, environment-friendly boron-free polymer polyvinyl alcohol-based ultra-light clay and preparation method thereof

A polyvinyl alcohol-based, ultra-light clay technology, used in titanate chelating agents, environmentally friendly boron-free polymer polyvinyl alcohol-based ultra-light clays and their preparation fields, to achieve bright color, no cracks, and excellent tensile properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

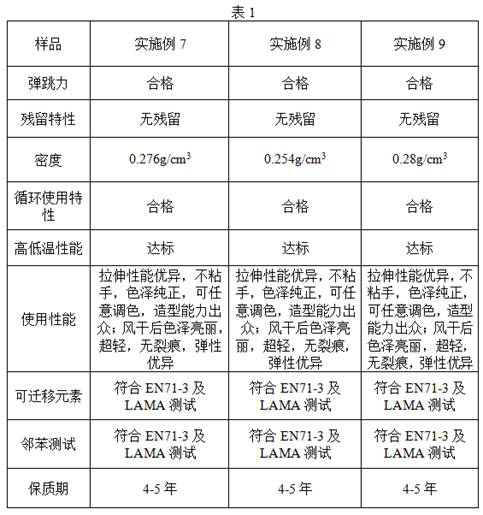

Examples

preparation example Construction

[0030] The preparation method of titanate chelating agent, 20-30 parts of Tyzor371, 10-20 parts of Tyzor212, 8-12 parts of polyacrylamide, 15-25 parts of sodium hexametaphosphate, add 25-34 parts of water, in 90- Stir at 95°C to react into a gel to obtain a gel-like substance, which is a titanate chelating agent. After obtaining the gel-like substance, you can also add 1 part of phenoxyethanol preservative and keep it for later use.

[0031] The environment-friendly boron-free polymer polyvinyl alcohol-based ultra-light clay includes the following raw materials by weight: 60-75 parts of water; 5-15 parts of polyvinyl alcohol, the average degree of polymerization of polyvinyl alcohol is greater than or equal to 2000; titanate 0.1-0.3 parts of chelating agent, 1-3 parts of water-soluble food grade pigment, 8-15 parts of microsphere foaming agent, 1-3 parts of lubricant, 3-8 parts of humectant, 1-5 parts of water-retaining agent, surface active 0.1-0.3 part of the agent, 0.1-0.3...

Embodiment 1

[0047] Titanate chelating agent: add 25 parts of Tyzor371, 15 parts of Tyzor212, 10 parts of polyacrylamide and 20 parts of sodium hexametaphosphate into 29 parts of water, stir at 90-95 ° C, react into a gel, and obtain The gel-like substance is a titanate chelating agent.

Embodiment 2

[0049] The preparation method of titanate chelating agent is to add 20 parts of Tyzor371, 10 parts of Tyzor212, 8 parts of polyacrylamide and 15 parts of sodium hexametaphosphate into 25 parts of water, stir at 90-95 ° C, and react to form a gel shape to obtain a gel-like substance, which is a titanate chelating agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com