Ultrasonic vibrator for drawing titanium and titanium alloy wires

A titanium alloy wire and ultrasonic technology, which is applied in the direction of fluid and wire drawing die using vibration, can solve the problems of slow drawing processing speed and low drawing processing accuracy, and achieve the effect of simple excitation, large amplitude and high strength and rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

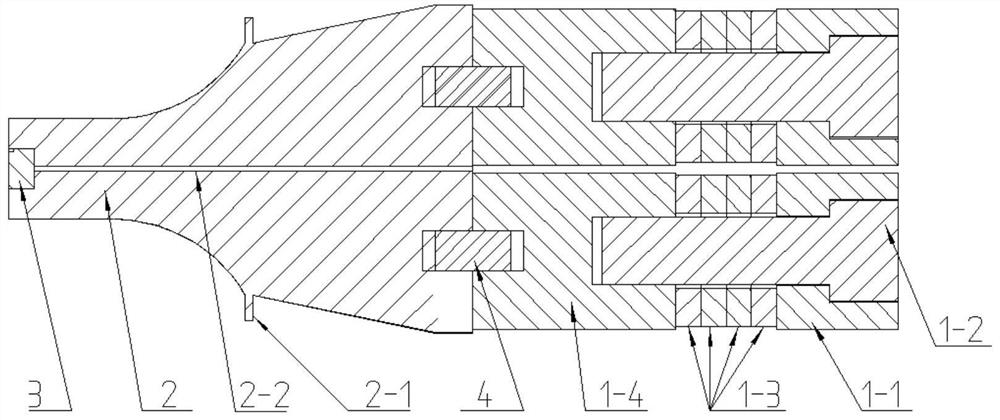

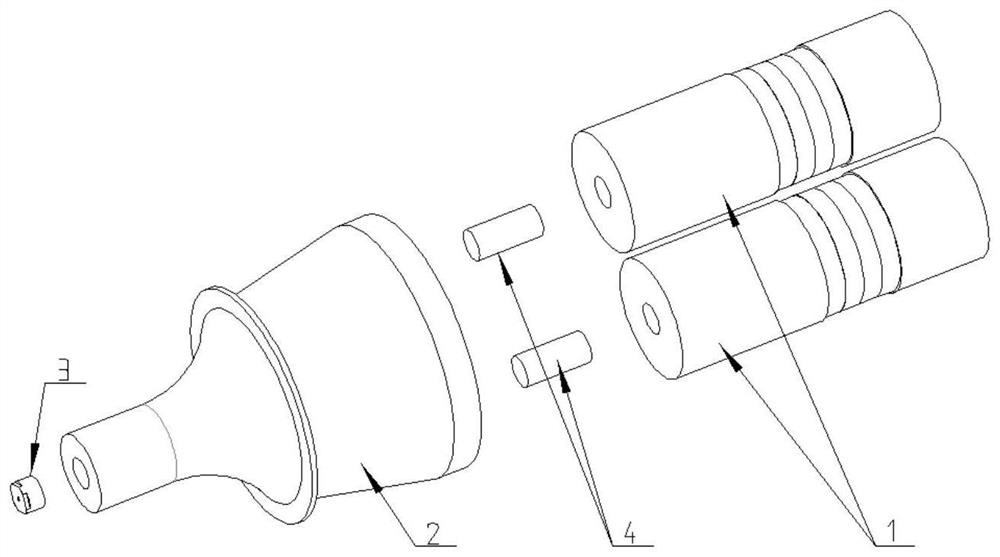

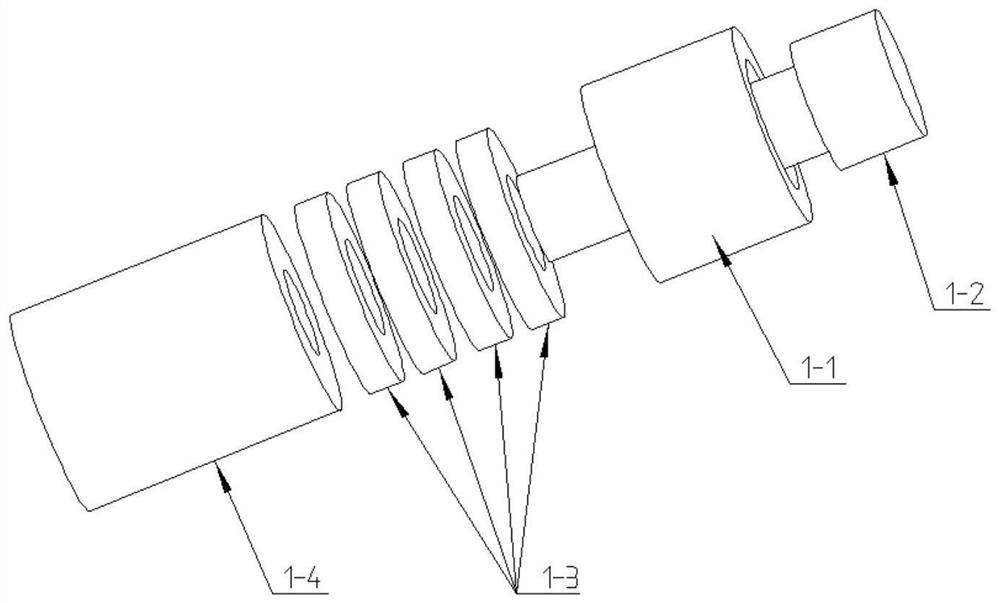

[0063] During the drawing process of titanium and titanium alloy wire, the ultrasonic vibrator drawn from the titanium and titanium alloy wire is installed on the abutment through the clamp and the flange. After installation, the titanium and titanium alloy wire pass through the drawing die and After passing through the wire hole, the ultrasonic vibrator is started, and the titanium and titanium alloy wires are processed by the ultrasonic vibrator and ultrasonically drawn, and finally high-quality drawing is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com