Clamping and welding mechanism for pipe pile plate skirt roll welding equipment

A welding mechanism and coil welding technology, which is applied in the field of machinery, can solve the problems of large space occupation, heavy labor intensity, and high noise, and achieve the effect of saving space and stabilizing the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

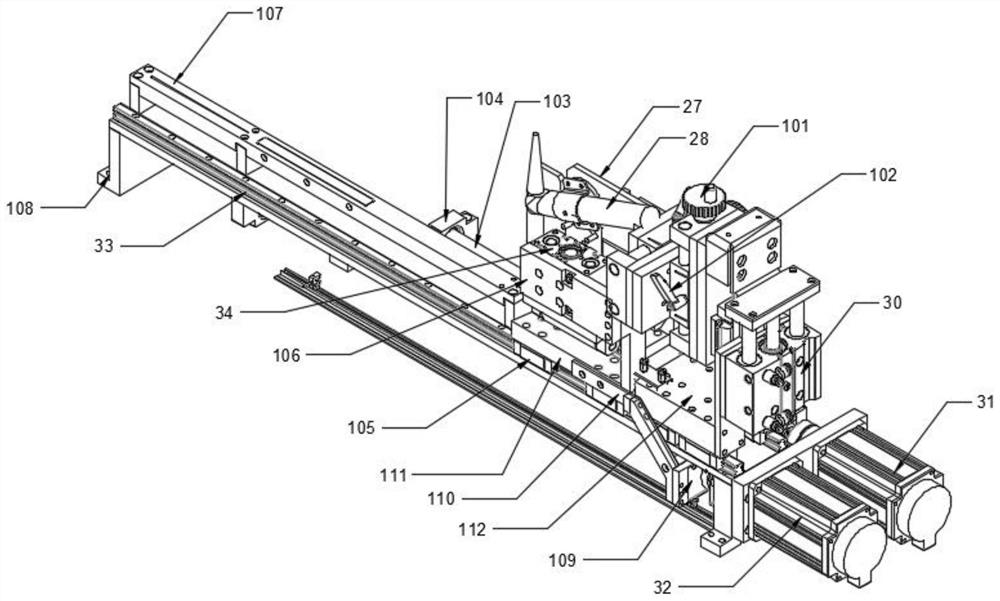

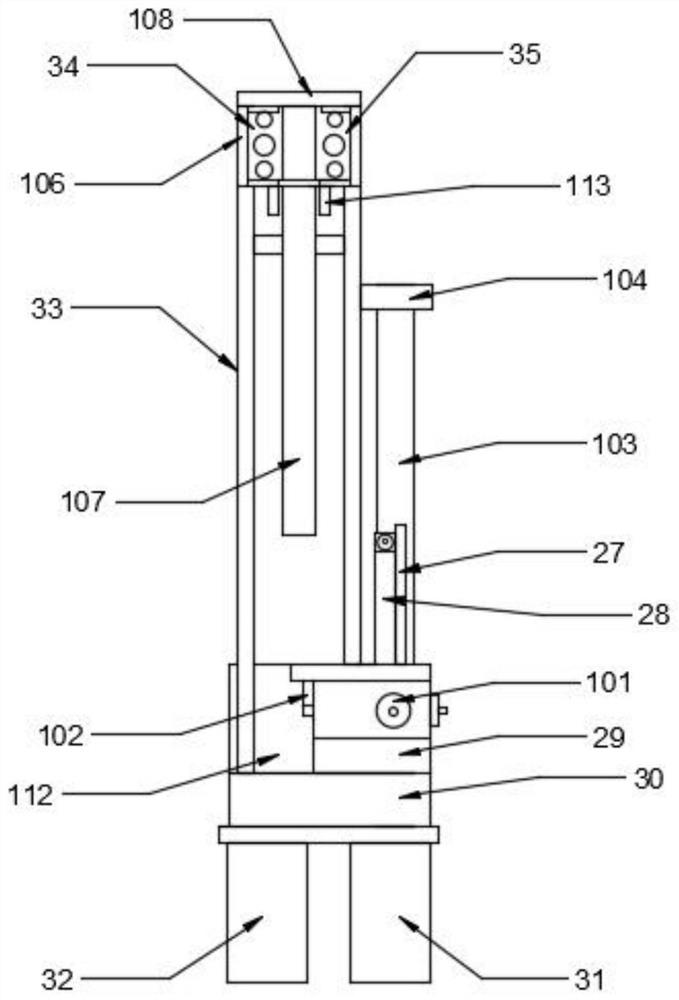

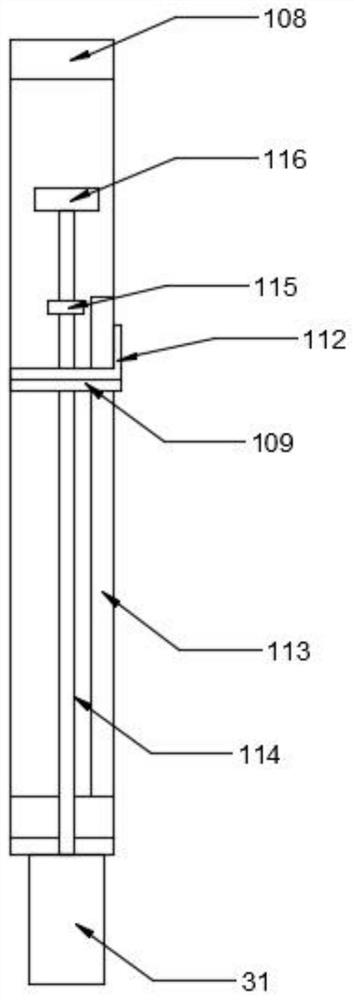

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] combined with figure 1 To attach image 3 , a clamping welding mechanism for pipe pile plate skirt roll welding equipment, including a few-shaped support plate 108, one side of the several-shaped support plate 108 is threadedly connected with a plate skirt clamping mechanism servo motor 32 and a welding torch Mechanism servo motor 31, the top of described several-shaped support plate 108 is connected with slide rail one 33, is provided with fixed plate 112 above one end of described slide rail one 33, and is provided with slide rail above slide rail one 33. block 105, the upper end of the slider 105 is fixedly connected with a slide plate 111, the upper side of the slide plate 111 is provided with a plate skirt positioning roller clamping cylinder 34, and the other side above the slide plate 111 is provided with a plate skirt fixed clamping Cylinder ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap