Electroplating process capable of improving efficiency and electroplating bath

A technology of electroplating process and electroplating tank, which is applied in the direction of electrolysis process, electrolysis components, current conduction devices, etc., can solve the problems of lack of technical personnel and high technical personnel, and achieve the effect of good quality, constant quality and less time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1 discloses an electroplating process that can improve efficiency. The moving direction of the workpiece is the same as the length direction of the electroplating tank. The length of each tank is 1 meter, and the casting speed is 21.5 m / min. Above-mentioned a kind of electroplating process that can improve efficiency comprises the following steps:

[0056] 1. Hot water washing: Put the workpiece into water heated to 50°C for hot cleaning. After thermal cleaning, put the workpiece into water with a pH of 7.5 for washing. Wherein, the section number of the thermal cleaning tank is 1, and the section number of the water washing tank is 3.

[0057] 2. Degreasing: put the workpiece into the degreasing liquid, and power on for degreasing. The degreasing liquid includes degreasing powder with a concentration of 60g / L, and the Baume degree of the degreasing liquid is 8°Bé. The current is 25A and the temperature is 55°C. After degreasing, put the workpiece into wa...

Embodiment 2-6

[0071] Embodiment 2-6 discloses a kind of electroplating process that can improve efficiency, and its steps are identical with embodiment 1, and the cell number, electric current, pulling speed of the tank (not including washing tank) of each step are shown in the table below.

[0072] The node number of the groove of each step in embodiment 1-6

[0073]

[0074] Electric current (A), pulling speed (m / min) of each step in embodiment 1-6

[0075]

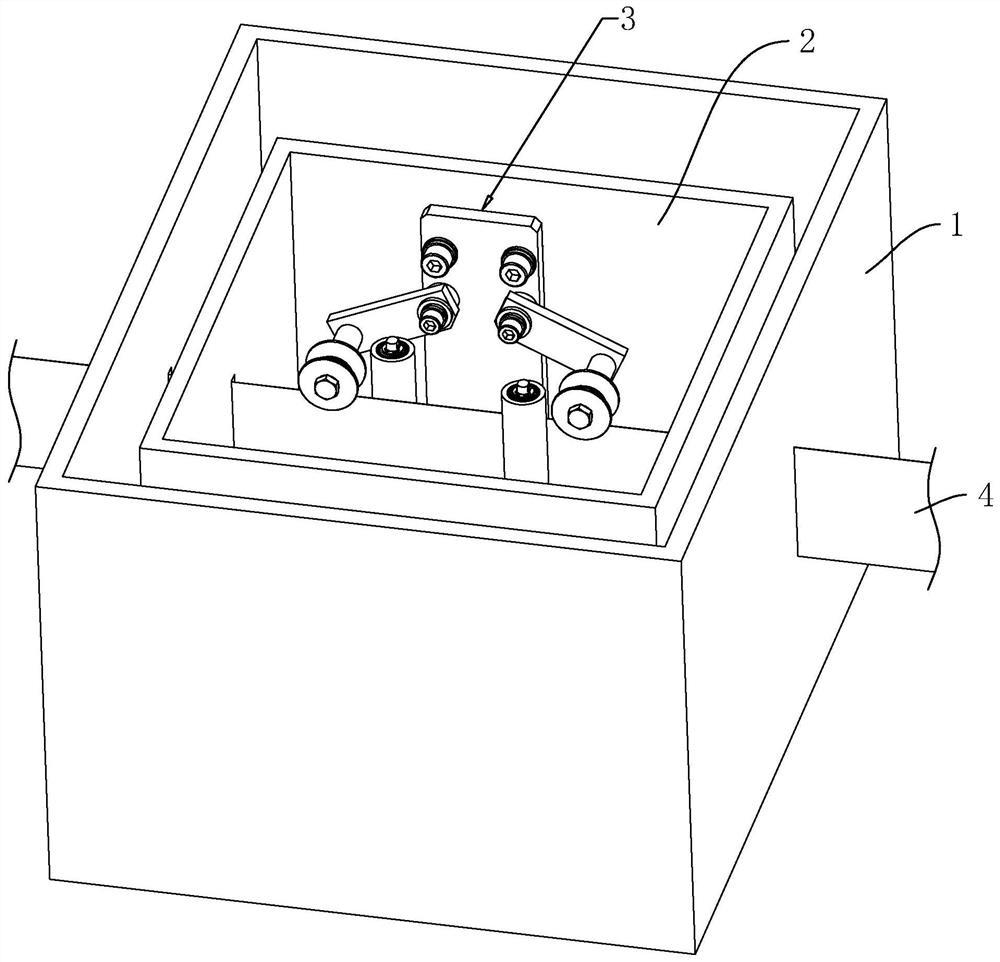

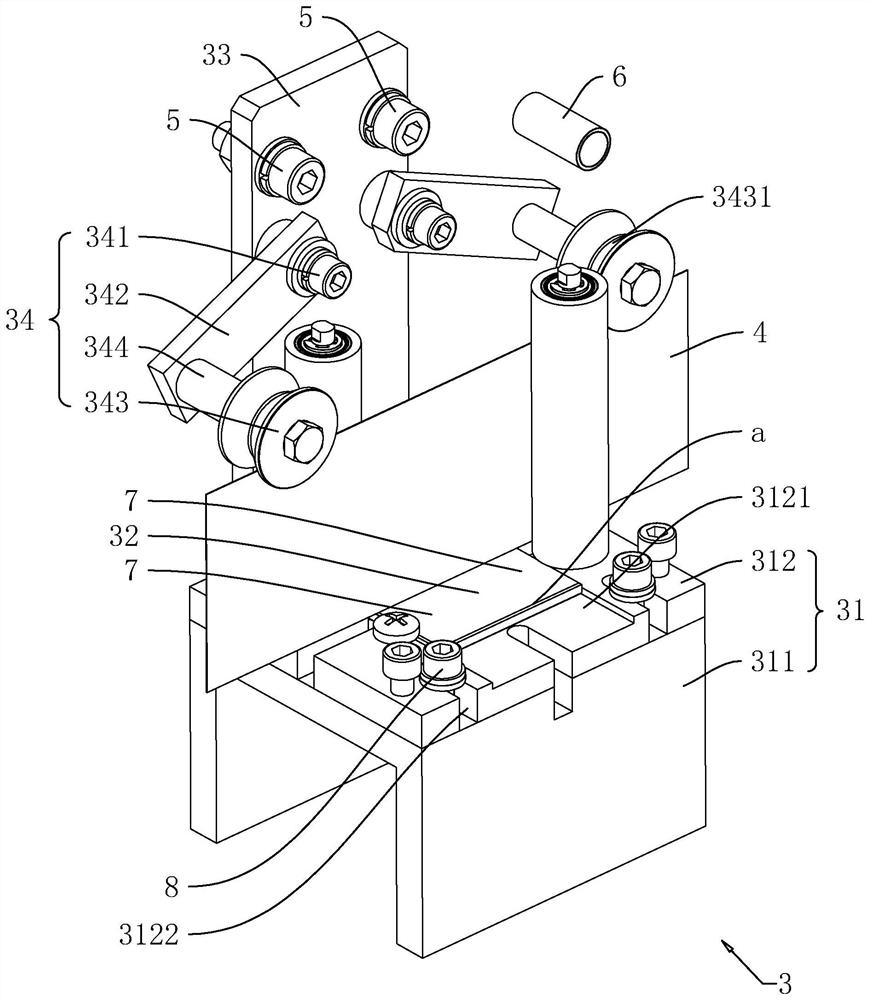

[0076] Among them, Embodiments 3-6 also disclose an electroplating tank, which is used in the steps of alkali copper plating, acid copper plating, nickel plating, pre-silver plating and silver plating. refer to figure 1 , the electroplating tank includes a mother groove 1 and a sub-groove 2 located in the mother groove 1, and a conductive seat 3 for conducting electricity is provided in the sub-groove 2, and the workpiece 4 passes through the mother groove 1 and the sub-groove 2, and is in contact with the conductive seat 3 ....

Embodiment 7

[0087] Embodiment 7 discloses an electroplating process that can improve efficiency. The difference from Embodiment 4 is that the total width of the conductive sheet 32 and the conductive plate 7 is 25 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com