System and method for regulating and controlling temperature of concrete dam

A concrete dam, concrete technology, applied in the direction of construction, infrastructure engineering, etc., can solve the problems of only cooling measures, many parts, changes in viscosity and fluidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

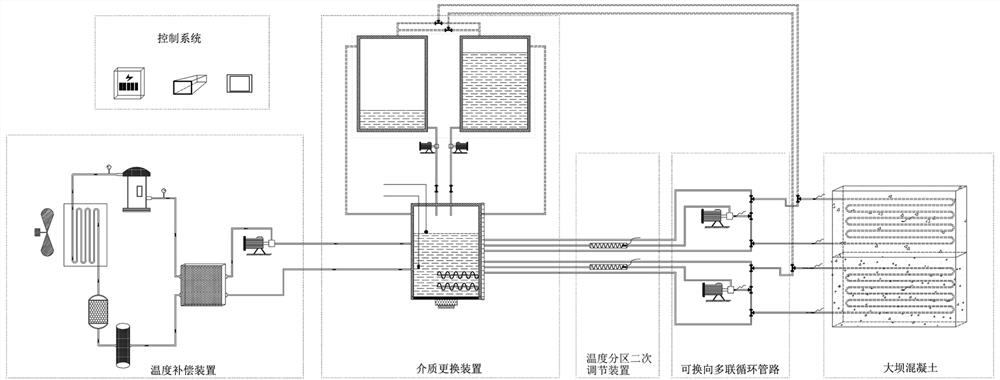

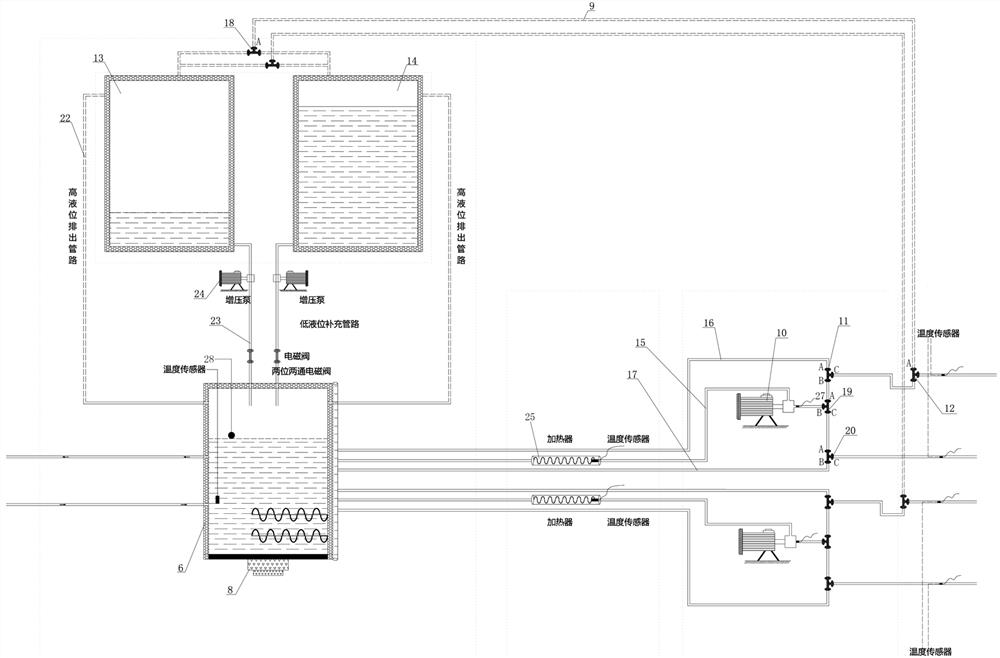

[0069] like Figure 1 to Figure 7 As shown, the following embodiments are provided, a system and method for regulating the temperature of a concrete dam, including a temperature compensation source, a regulating medium, liquid level monitoring and adjustment, a medium replacement device, a reversible multi-connected output circulation pipeline, and two temperature zones Secondary regulating device, flow regulating device, control system.

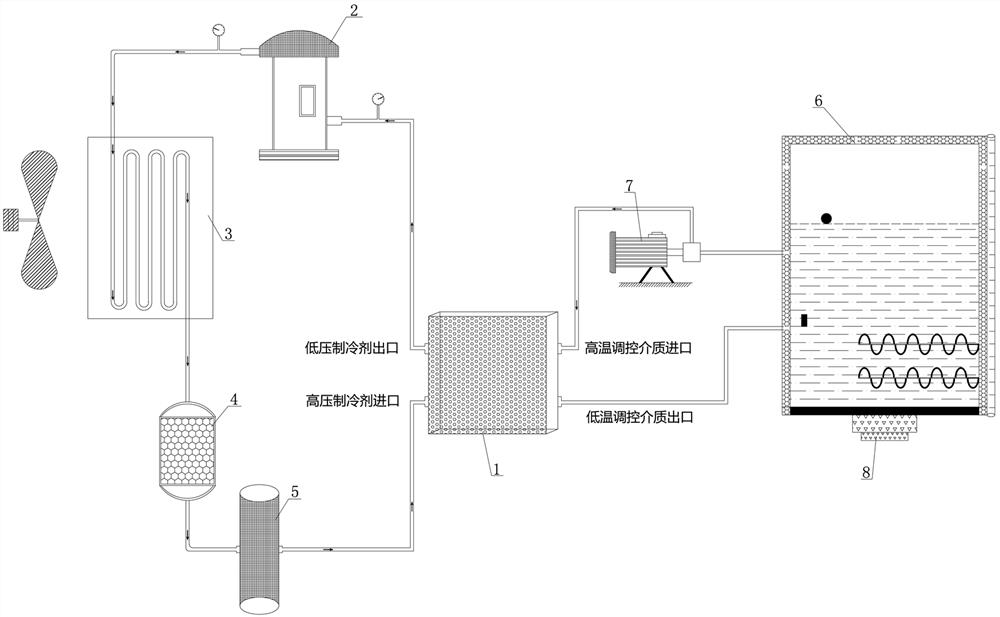

[0070] 1. As for the temperature compensation source, it has the function of heating and cooling the regulating medium, and produces the regulating medium with variable temperature according to the needs, and provides it to the external reversible multi-connected output circulation pipeline;

[0071] The temperature compensation source is composed of a refrigeration compressor, a condenser, a condenser fan, an evaporator, an expansion valve, a heater, a medium storage tank, an internal circulation pump, and a refrigerant.

[0072] The compr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com