Automatic drill rod blowout prevention buckle cleaning machine

An automatic drilling and blowout prevention technology, which is applied in the direction of drill pipes, drill pipes, drilling tools, etc., can solve the problems of low degree of automation and easy pollution of the drill floor, and achieve the effects of reducing personnel, facilitating quick docking, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

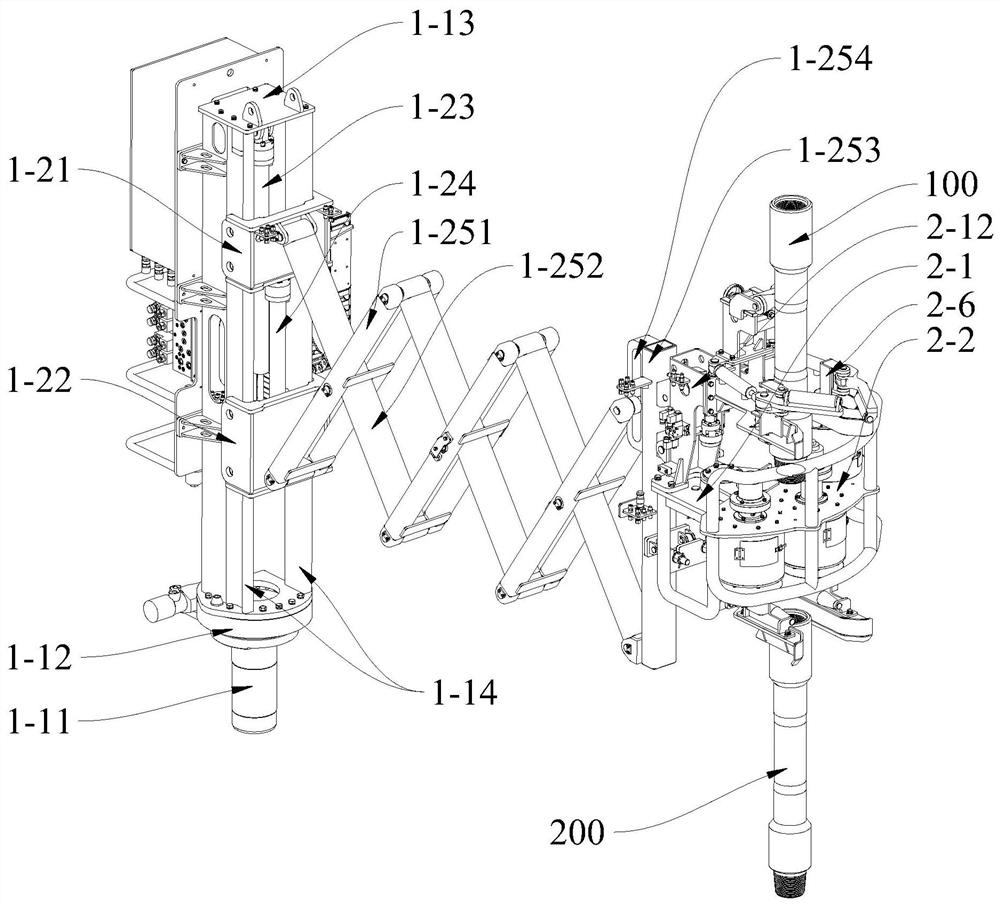

[0081] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings. Among them, the directional nouns such as "up" and "down" mentioned in this article are based on figure 1 orientation as a reference.

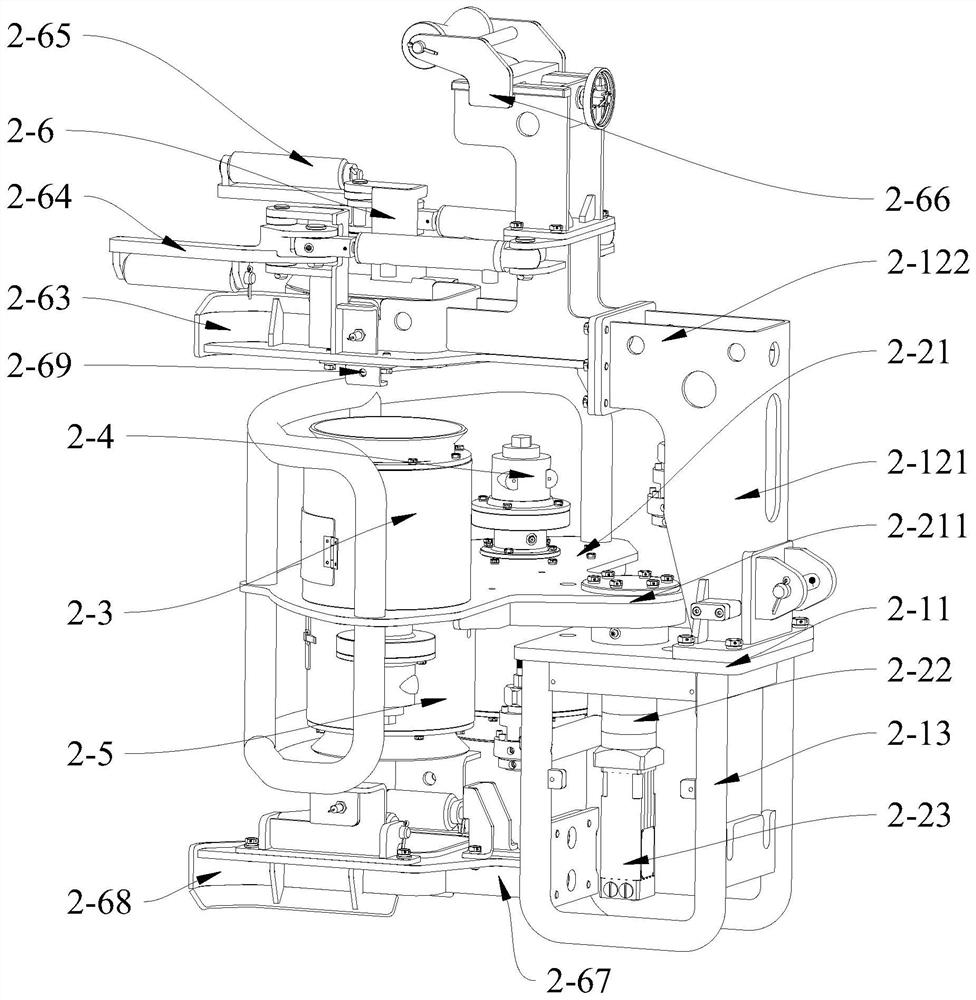

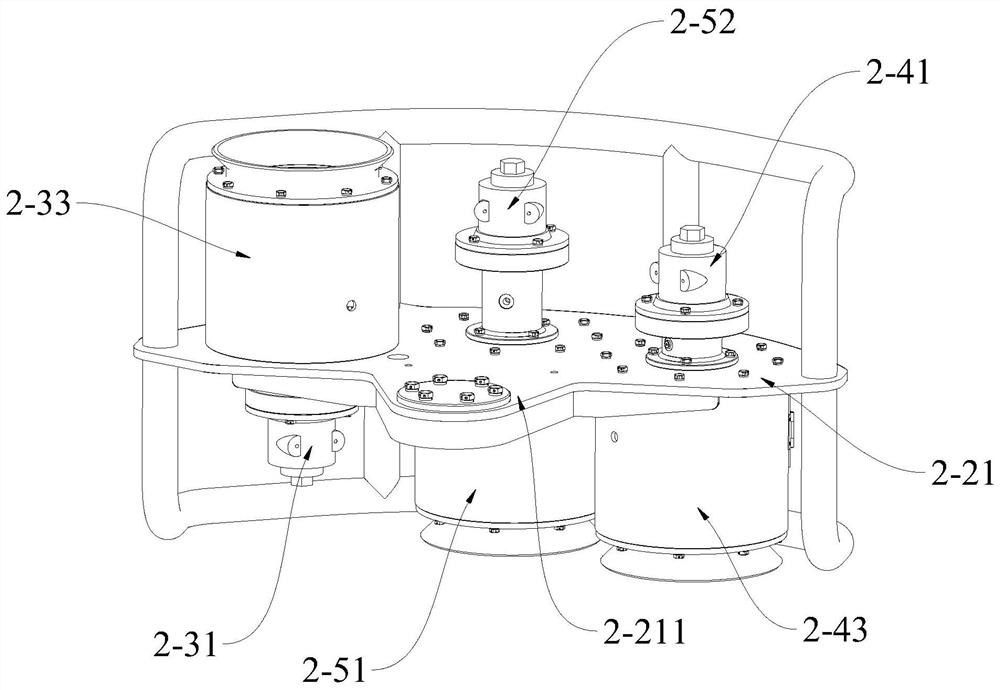

[0082] The embodiment of the present invention proposes an automatic drill pipe anti-blowout cleaning machine, which solves the low degree of automation in the operation process of drill pipe cleaning, thread oil application and drill pipe butt jointing and the technology that the drill pipe disassembly process is very easy to pollute the drill floor question. The automatic drill pipe anti-blowout cleaning buckle machine includes a manipulator assembly and a working assembly. The working assembly includes a buckle cleaning device and a blowout prevention device. The buckle cleaning device includes a turntable mechanism 2-2, a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com