Enhanced heat transfer resistance reduction energy-saving heat exchange plate for broken line type printed circuit plate heat exchanger

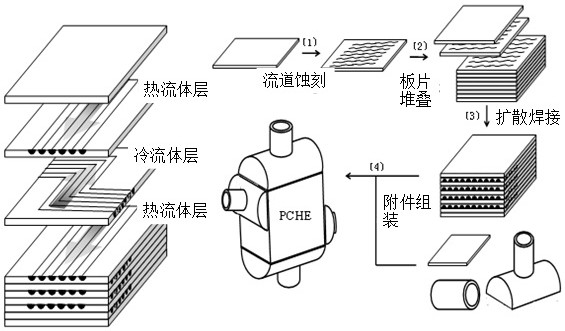

A printed circuit board and enhanced heat transfer technology, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc. Reduce the pressure drop of the working medium, increase the disturbance of the boundary layer, etc., and achieve the effect of reducing the pressure drop of the working fluid, uniform flow distribution, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

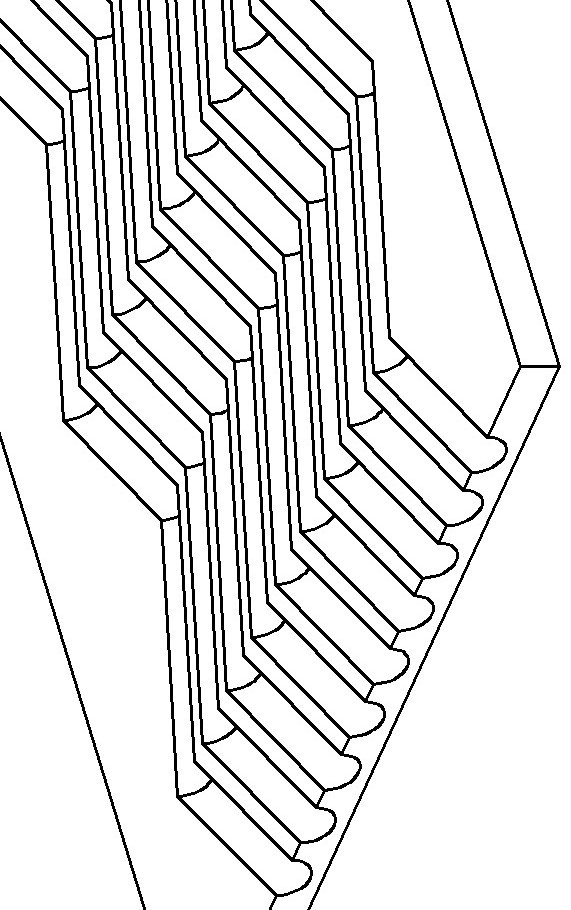

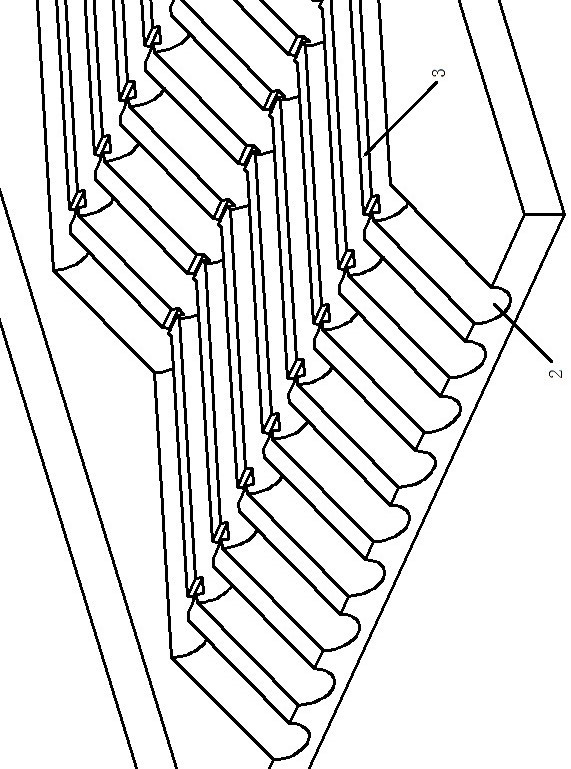

[0028] Such as image 3 As shown, the present invention is an energy-saving heat transfer plate for enhancing heat transfer and reducing drag for a folded line type printed circuit board heat exchanger. A balance reinforcement seam 1 is processed downstream of the bending angle, and the balance reinforcement seam 1 and the fold line flow channel 2 are integrally formed by chemical etching process.

[0029] The balance strengthening seam 1 is periodically arranged along the flow direction. The cross section of the balance strengthening seam 1 is semicircular, and its direction is perpendicular to the flow direction. On the same side of the heat exchange plate bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com