Rapid welding device for instrument production and operation method thereof

An instrumentation and fast welding technology, which is applied in welding equipment, welding equipment, auxiliary devices, etc., can solve the problems that the welding torch cannot be aimed at the splicing seam, the welding time is long, and the welding effect is poor, so as to improve welding efficiency and improve welding efficiency. Quality, guarantee the effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

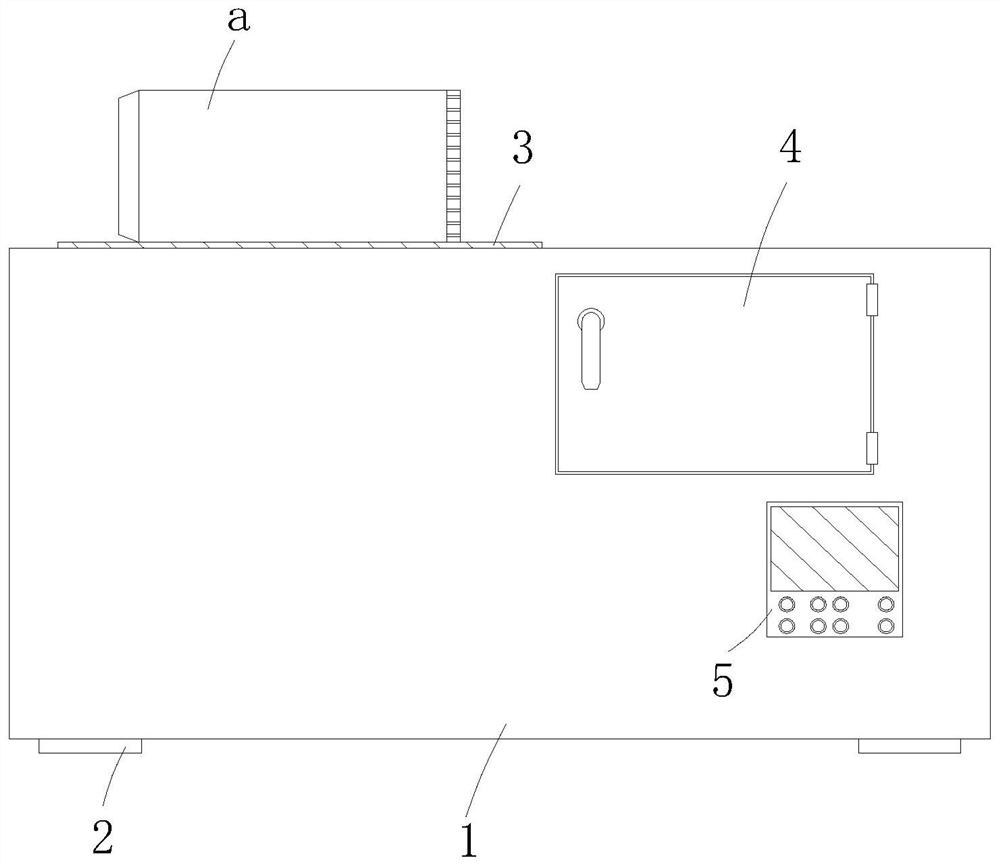

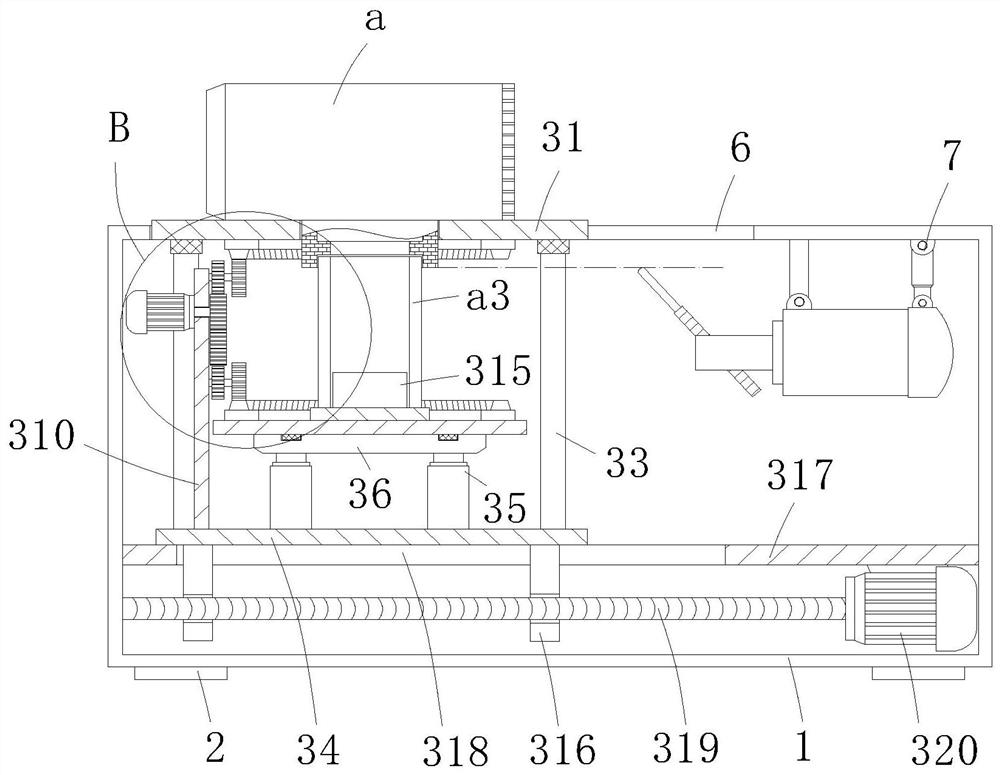

[0033] A rapid welding device for instrumentation production, comprising an outer case 1 and a plurality of supporting feet 2 installed at the lower end of the outer case 1, a splicing mechanism 3 is provided on the upper part of the inner cavity of the outer case 1, and one side of the splicing mechanism 3 is provided There is a welding mechanism 7 for connecting the instrument body a after splicing;

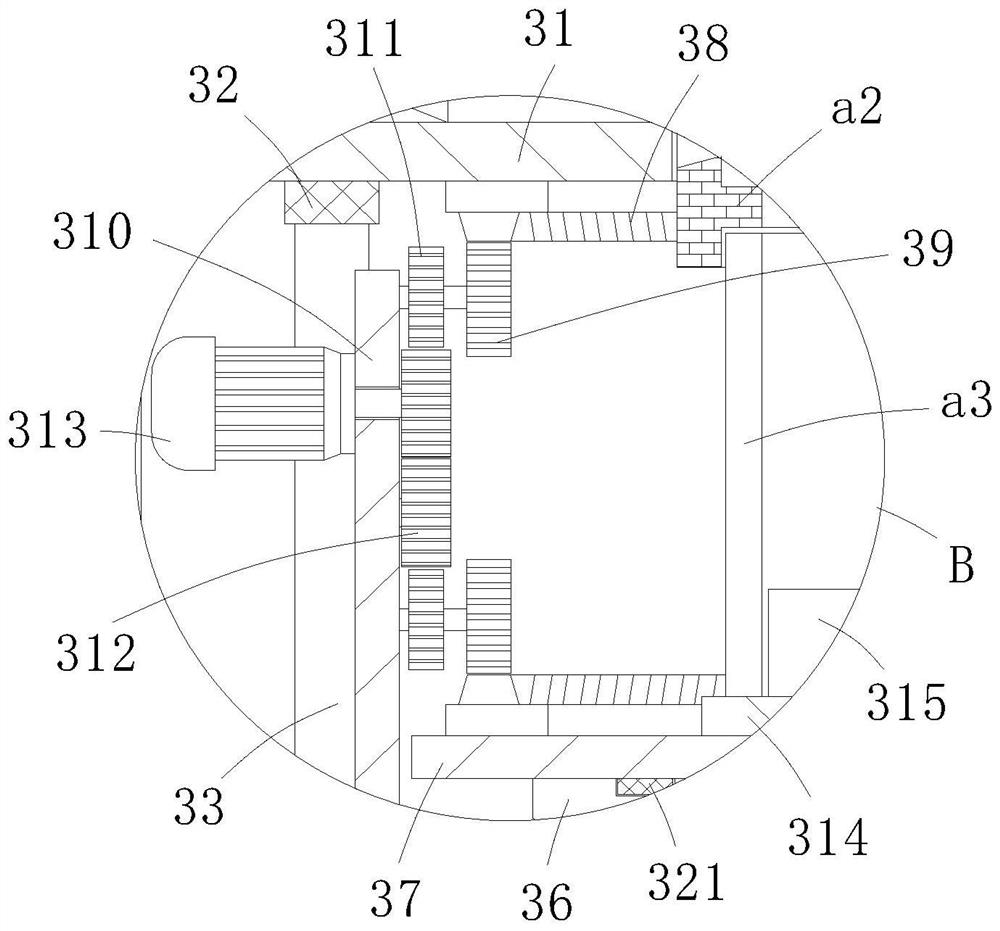

[0034] Such as Figure 5 As shown, the instrument body a includes meter head a1, meter holder a2 and branch pipe a3, wherein the meter holder a2 and the meter head a1 are integrally formed, and when the branch pipe a3 is spliced, its upper part is inserted into the lower port of the meter holder a2, and the welding mechanism 7 It is necessary to weld the splicing seam of the instrument body a after assembly.

[0035] In this example, if figure 2 with 3 As shown, the splicing mechanism 3 includes a meter tray 31 inserted on the top wall of the outer chassis 1, the middle part...

Embodiment 2

[0045] The present invention also provides an operation method based on the above-mentioned rapid welding device for instrumentation production, the specific steps of the operation method are:

[0046] S1. Put the branch pipe a3 of the instrument body a into the inner cavity of the outer cabinet 1 through the preset hole, and complete the vertical positioning of the branch pipe a3 through the branch pipe seat 314 and the branch pipe positioning block 315 on the lower chassis 37;

[0047] S2. The meter head a1 of the instrument body a is placed on the meter head tray 31, and the meter holder a2 is placed in the preset hole to complete the vertical positioning of the meter holder a2 and the branch pipe a3;

[0048] S3. Drive the lower chassis 37 upward through the lifting cylinder 35, insert the vertically positioned branch pipe a3 into the instrument holder a2, and complete the splicing of the instrument body a;

[0049] S4, drive the screw rod 319 to rotate through the servo m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com