Construction process for preventing welded junction of water-cooled wall tube from cracking

A technology of water-cooled wall tubes and construction technology, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., and can solve problems such as large welding stress, poor operating conditions of water-cooled walls, and large alternating stress, so as to reduce welding stress , Elimination of restraint stress, elimination of weak links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

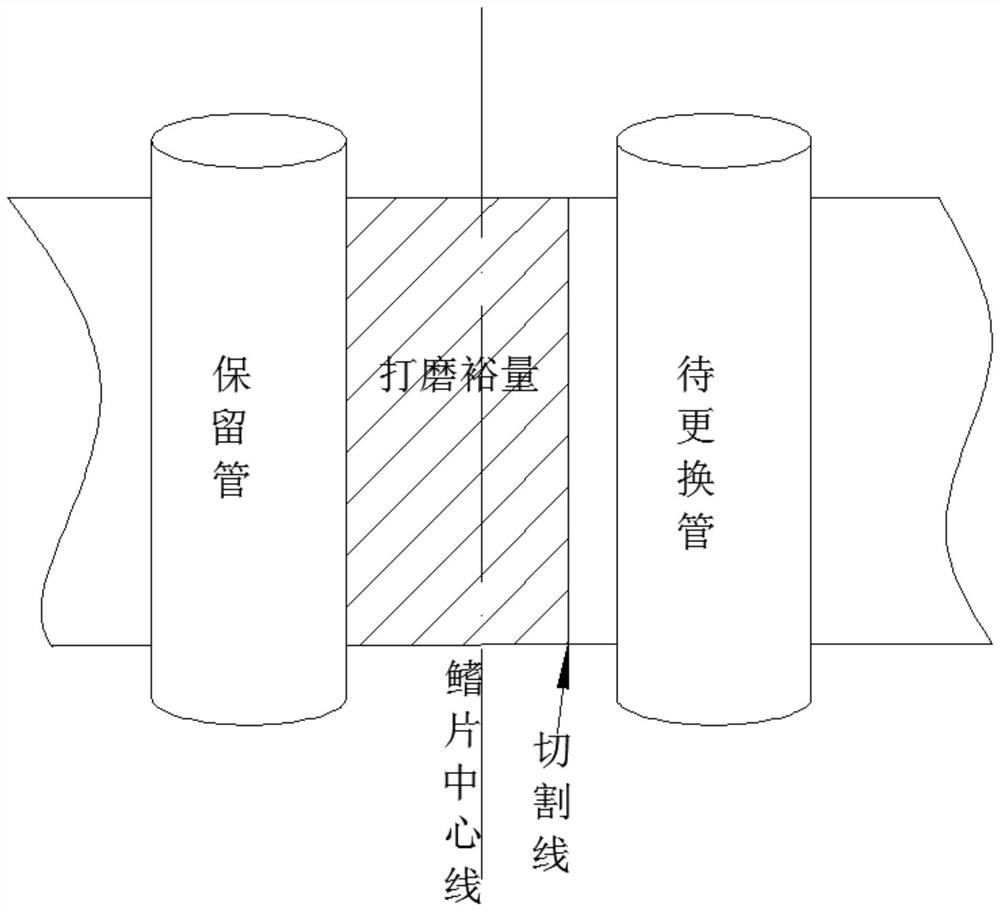

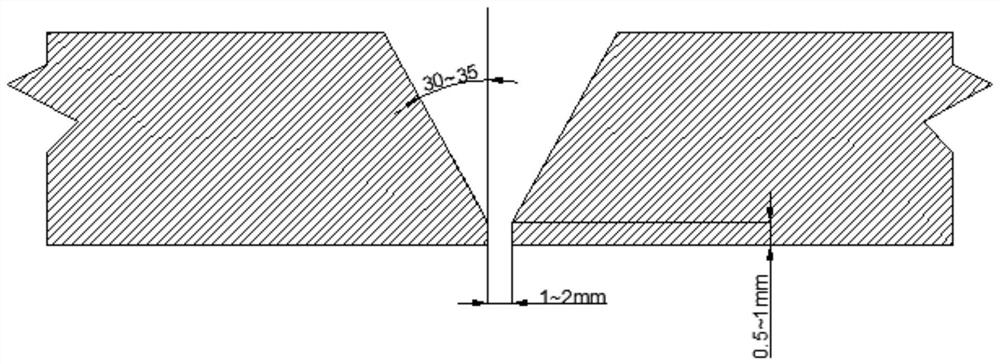

[0039] see figure 1 and figure 2 , a construction technique for preventing weld cracks of water-cooled wall tubes described in a preferred embodiment of the present invention, comprising:

[0040] 1. Construction preparation

[0041] 1.1. Welders, fitters and welding heat treatment operators should participate in technical assessment according to regulations and obtain corresponding qualifications.

[0042] 1.2. Before welding, the quality certification documents of welding materials should be checked, and the appearance of welding materials should be checked randomly, and they can be used only after they are qualified.

[0043] 1.3. The construction site is well prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com