Nickel-based alloy welding powder as well as manufacturing method and using method thereof

A technology of nickel-based alloys and production methods, applied in welding equipment, manufacturing tools, welding media, etc., can solve problems such as weld crack fusion, welding power fluctuations, and affecting engineering applications, and achieve increased crack resistance and weld hardness Low, less risk of cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

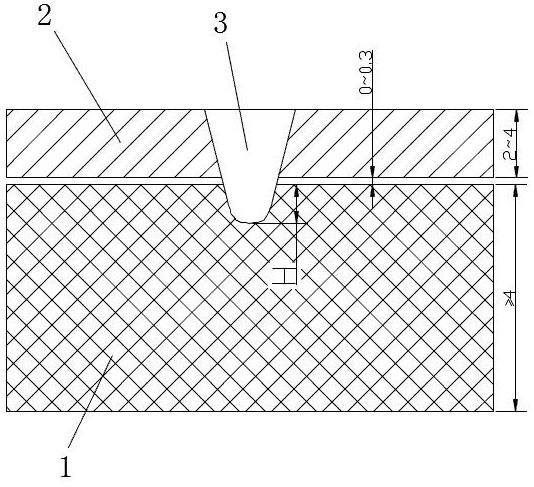

Image

Examples

Embodiment 1

[0051] Soldering powder was prepared by adopting the formula whose chemical composition was the lower limit of the application, and the welding process parameters were the parameters in the middle area of the application to complete the welding joint of Example 1.

[0052] A nickel-based alloy welding powder for welding carbon steel and cast iron, the nickel-based alloy welding powder includes the following components by mass: C: 0.41%, Si: 2.31%, P: 0.002%, S: 0.002 %, Fe: 27.1%, Ce: 0.012%, Y: 0.012%, Ni is the balance, and the solder powder specification is 100-200 mesh.

[0053] A method for using the nickel-based alloy solder powder, comprising the following steps:

[0054] (1) Base material preparation:

[0055] The chemical composition of gray cast iron used in this application is as follows in parts by mass: C: 3.21%, Si: 1.83%, Mn: 0.94%, S: 0.11%, P: 0.14%, minimum tensile strength 250 MPa, thickness 10 mm .

[0056] The chemical composition of carbon steel used...

Embodiment 2

[0063] Soldering powder was prepared by adopting the formula whose chemical components were the upper limit of the application, and the welding process parameters were the parameters in the middle area of the application to complete the welding joint of Example 2.

[0064] A nickel-based alloy welding powder for welding carbon steel and cast iron, the nickel-based alloy welding powder includes the following components by mass: C: 0.59%, Si: 2.58%, P: 0.009%, S: 0.004 %, Fe: 29.8%, Ce: 0.058%, Y: 0.048%, Ni is the balance, and the solder powder specification is 100-200 mesh.

[0065] A method for using the nickel-based alloy solder powder, comprising the following steps:

[0066] (1) Base material preparation

[0067] The chemical composition of gray cast iron used in this application is as follows in parts by mass: C: 3.21%, Si: 1.83%, Mn: 0.94%, S: 0.11%, P: 0.14%, minimum tensile strength 250MPa, thickness 5mm.

[0068] The chemical composition of carbon steel used in th...

Embodiment 3

[0075] Each chemical composition is used as the formula in the middle area of the application to prepare welding powder, and the welding process parameters are the parameters in the middle area of the application to complete the welding joint of Example 3.

[0076] A nickel-based alloy welding powder for welding carbon steel and cast iron, the nickel-based alloy welding powder includes the following components in parts by mass: C: 0.51%, Si: 2.45%, P: 0.005%, S: 0.004 %, Fe: 28.5%, Ce: 0.035%, Y: 0.03%, Ni is the balance, and the solder powder specification is 100-200 mesh.

[0077] A method for using the nickel-based alloy solder powder, comprising the following steps:

[0078] (1) Base material preparation

[0079] The chemical composition of gray cast iron used in this application is as follows in parts by mass: C: 3.21%, Si: 1.83%, Mn: 0.94%, S: 0.11%, P: 0.14%, minimum tensile strength 250MPa, thickness 8mm.

[0080] The chemical composition of carbon steel used in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com