Machine-sprayed putty material and preparation method thereof

A technology of putty and base material, applied in the field of machine-sprayed putty material and its preparation, can solve the problems of inability to putty, high pumping resistance, strong thixotropy of putty, etc. The effect of the flat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] A preparation method for machine-sprayed putty material, comprising the following steps:

[0061] Mixed base material, water reducing agent, cellulose ether, modified hydroxypropyl starch ether and filler;

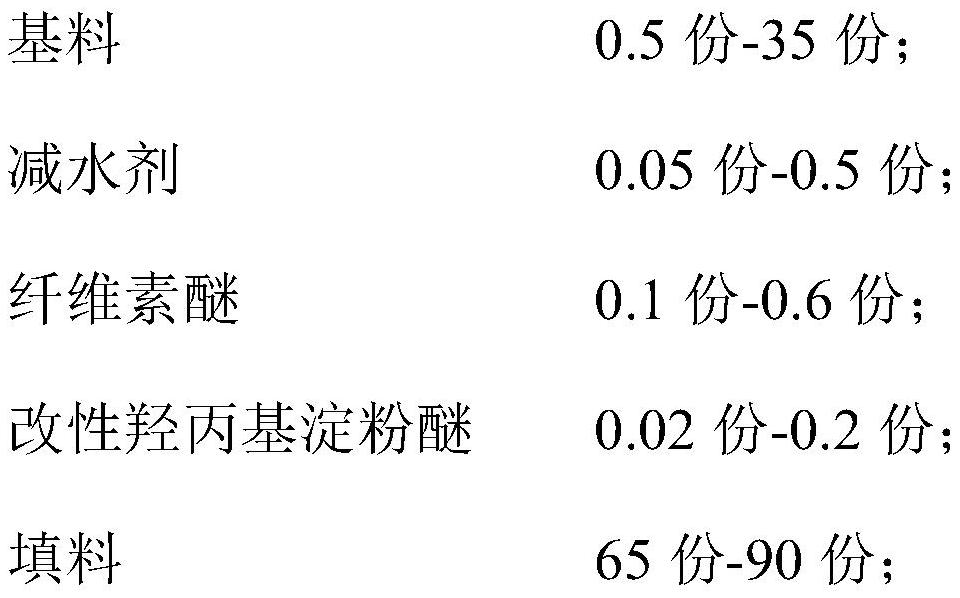

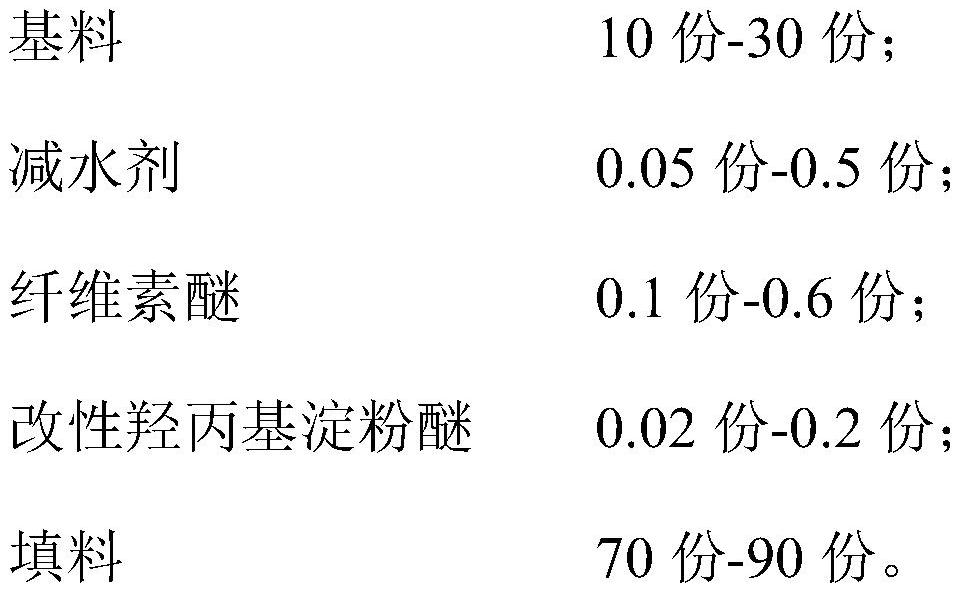

[0062] The parts by weight of the base material are 0.5-35 parts; the parts by weight of the water reducing agent are 0.05-0.5 parts; the parts by weight of cellulose ether are 0.1-0.6 parts; The parts by weight are 0.02-0.2 parts; the parts by weight of the filler are 65-90 parts; the water-reducer is selected from naphthalene-based water-reducer and / or melamine water-reducer; the cellulose ether is at 20 The viscosity at °C is 20000mPa·s-40000mPa·s; the degree of substitution of the modified hydroxypropyl starch ether is 0.05-0.08, and the viscosity at 20°C is 400mPa·s-1200mPa·s.

[0063] A method for using a machine-sprayed putty material, comprising the following steps:

[0064] Spray the putty material and water on the mixer, let it stand after stirring, and ...

Embodiment 1

[0072] This embodiment provides a machine-sprayed putty material and its preparation method and use method, the steps are as follows:

[0073] In parts by weight, weigh 16 parts of white cement, 3 parts of vinyl acetate-ethylene latex powder, 0.3 part of water reducing agent, 0.3 part of hydroxypropyl methylcellulose ether, 0.08 part of modified hydroxypropyl starch ether, 0.5 parts of defoamer, 20 parts of ground calcium carbonate, 30 parts of kaolin, 30 parts of talcum powder.

[0074] Preparation method: the above-mentioned white cement, vinyl acetate-ethylene latex powder, water reducer, hydroxypropyl methylcellulose ether, modified hydroxypropyl starch ether, defoamer, ground calcium carbonate, kaolin and talcum powder Pour into mixing equipment and mix evenly, then weigh and pack.

[0075] How to use: Weigh 40 parts of water, pour in other powders, stir at high speed for 4 minutes, then let stand for 10 minutes, then stir for 2 minutes.

Embodiment 2

[0077] This embodiment provides a machine-sprayed putty material and its preparation method and use method, which are basically the same as in Embodiment 1, the only difference being that the filler is different, and the steps are as follows:

[0078] In parts by weight, weigh 16 parts of white cement, 3 parts of vinyl acetate-ethylene latex powder, 0.3 part of water reducing agent, 0.3 part of hydroxypropyl methylcellulose ether, 0.08 part of modified hydroxypropyl starch ether, 0.5 parts of defoamer, 40 parts of kaolin, 40 parts of talcum powder.

[0079] Preparation method: Pour the above white cement, vinyl acetate-ethylene latex powder, water reducer, hydroxypropyl methylcellulose ether, modified hydroxypropyl starch ether, defoamer, kaolin and talc into the mixing equipment Mix well, weigh and pack.

[0080] How to use: Weigh 40 parts of water, pour in other powders, stir at high speed for 4 minutes, then let stand for 10 minutes, then stir for 2 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com