Deceleration strip mounting device for highway construction

A technology for installing devices and speed bumps, which is applied to roads, roads, road signs, etc., can solve the problems of workers requiring high physical strength, occupying traffic arteries, and affecting the masses, so as to avoid traffic jams, reduce installation time, and reduce labor. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

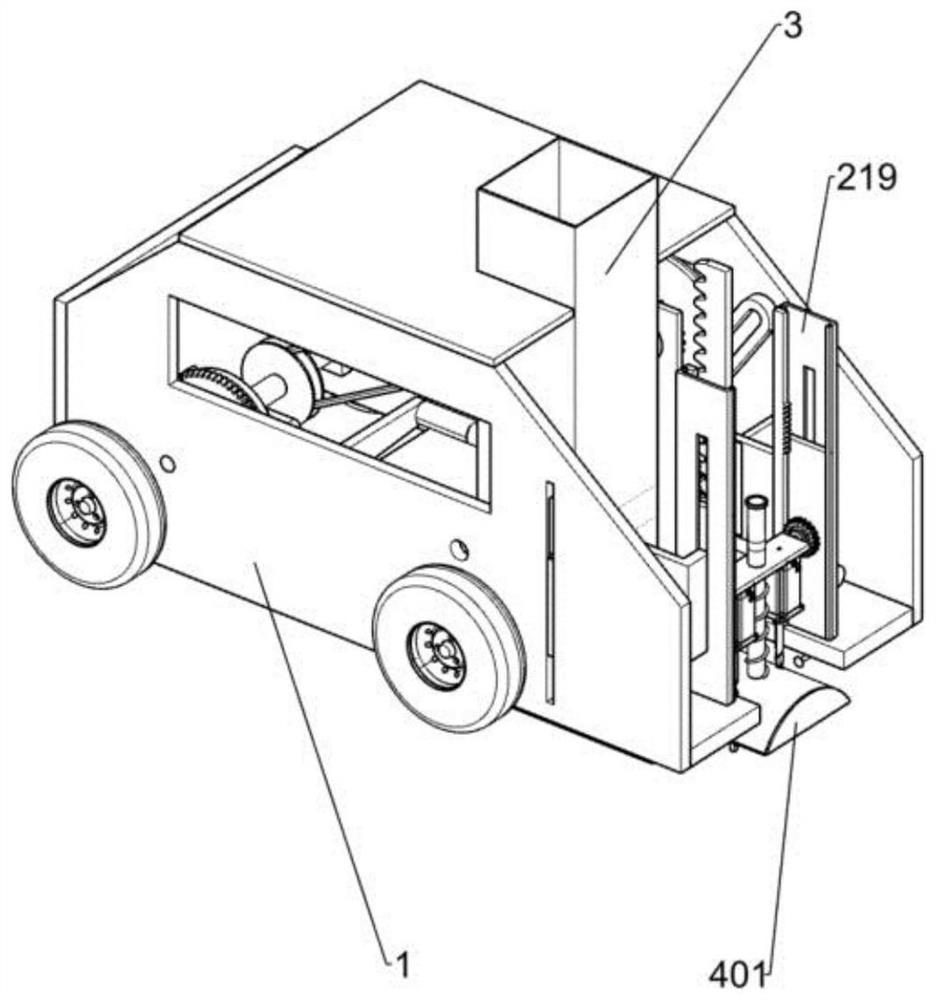

[0029] A speed bump installation device for road construction, such as Figure 1-5 As shown, it includes a car body 1, a power mechanism, a mounting mechanism and a pushing mechanism. In the middle position of the car body 1, the pushing mechanism is connected with the power mechanism, and the right rear side of the pushing mechanism is connected with the left side of the mounting mechanism.

[0030] Working principle: When preparing to install the deceleration belt, first manually put the deceleration belt to be installed into the pushing mechanism, start the power mechanism, and the power mechanism drives the pushing mechanism to push the deceleration belt into the installation mechanism one by one, and the installation mechanism will The deceleration belt in the mechanism is drilled and installed on the road. When the power mechanism drives the pushing mechanism to push the deceleration belt into the installation device, the power mechanism moves forward with the vehicle bo...

Embodiment 2

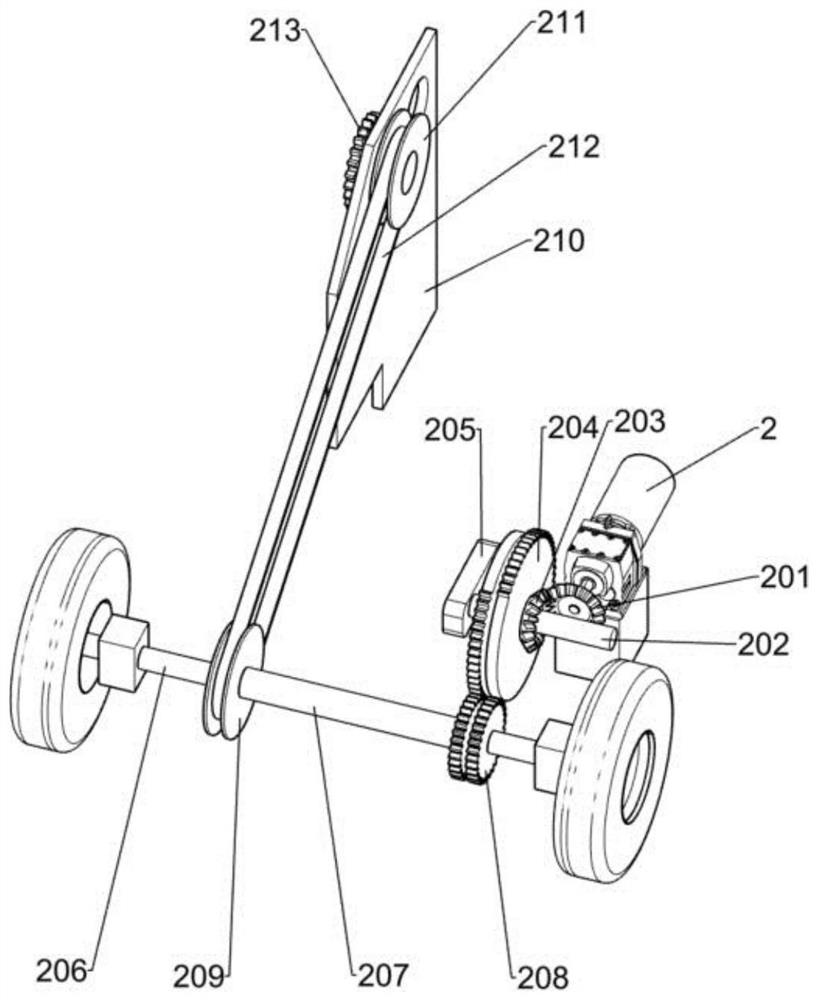

[0032] On the basis of Example 1, such as figure 2 As shown, the power mechanism includes a first motor 2, a first bevel gear 201, a first shaft 202, a second bevel gear 203, a missing tooth gear 204, a fixed frame 205, a second shaft 206, a sleeve 207, a first Straight gear 208, first pulley 209, first fixed plate 210, second pulley 211, belt 212, second spur gear 213, third spur gear 214, third shaft 215 and turntable 303, first motor 2. It is fixedly installed on the left front side inside the car body 1. The first bevel gear 201 is fixedly installed on the left end of the output shaft of the first motor 2. The fixing frame 205 is fixedly installed on the left front side inside the car body 1. The fixing frame 205 is located on the first motor 2, the first shaft 202 is rotatably mounted on the front side of the upper end of the fixed frame 205, and the two toothless gears 204 are fixedly mounted on the rear side of the first shaft 202, and the middle position of the first ...

Embodiment 3

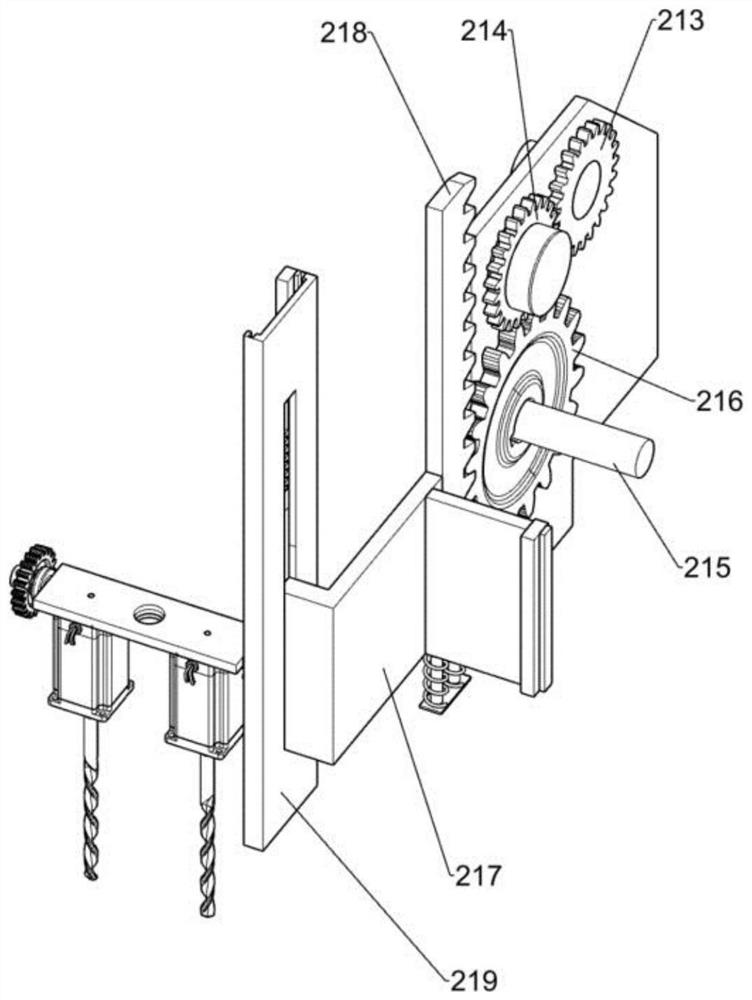

[0039] On the basis of embodiment 1 and embodiment 2, such as Figure 6As shown, a dust suction mechanism is also included. The dust suction mechanism includes a dust washing plate 4, a pressing plate 401, a second sliding column 402 and an elastic member. The dust washing plate 4 is fixedly installed on the front and rear sides of the lower right side of the car body 1 The second sliding column 402 is slidably installed in the middle of the second fixing plate 220, the pressing plate 401 is fixedly installed on the lower end of the second sliding column 402, the elastic member is sleeved on the second sliding column 402, and the elastic member is located between the second fixing plate 220 and the second fixing plate 220. Between the platen 401.

[0040] Working principle: when the carriage 217 moves down with the second fixed plate 220, the dust suction mechanism moves down with the second fixed plate 220, and when the pressure plate 401 is supported on the ground, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com