Aluminum alloy formwork construction method for variable-story-height building

A technology of aluminum alloy formwork and construction method, which is applied to the preparation of formwork/formwork/work frame, building components on site, construction, etc., which can solve the problems of confusion on the construction site, reduction of construction progress, and increase of construction costs. , to achieve the effect of improving efficiency, ensuring construction quality, and reducing one-time investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

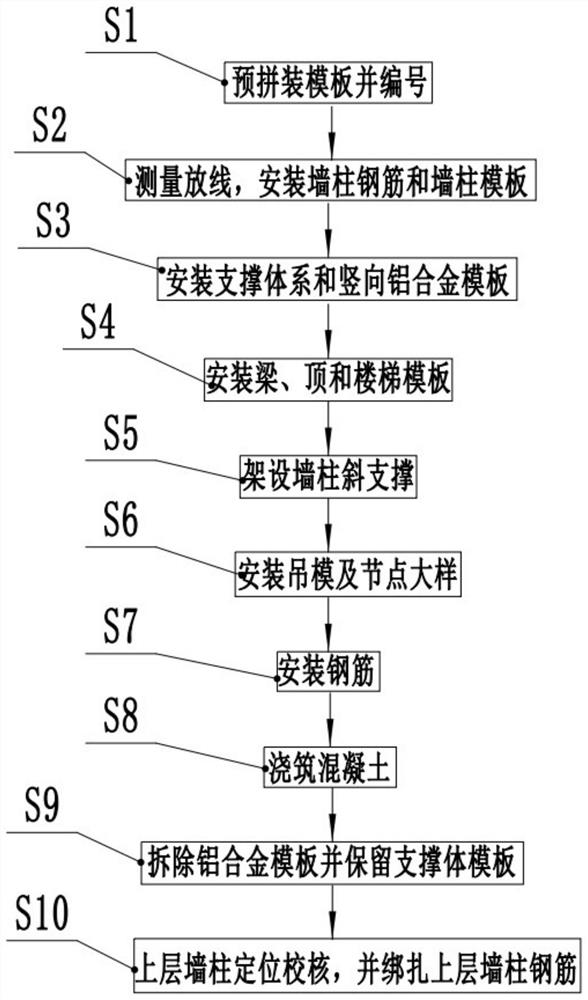

[0037] A kind of aluminum alloy formwork construction method of building with variable storey height (referring to figure 1 ), including the following steps:

[0038] S1: Pre-assemble and number the templates. The templates include standard templates and non-standard templates; by numbering the templates, it is possible to prevent materials from being stacked chaotically and cause idle work, and to improve construction efficiency.

[0039] S2: measure and set out, install the wall column steel bar and the wall column template, adjust the verticality and flatness of the wall; in the present embodiment, the template verticality allowable deviation is 5mm, and the flatness allowable deviation is 3mm. Composite control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com