Double-acting oil well pump

An oil well pump and double-acting technology, applied in the field of double-acting oil well pump, can solve the problem of low displacement of the oil well pump, and achieve the effects of convenient processing, simple structure and improving single well production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing:

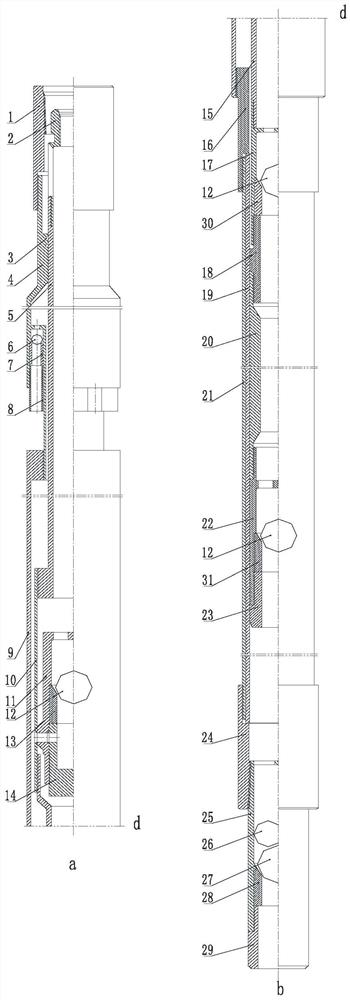

[0009] as attached figure 1 As shown, the double-acting oil well pump includes an upper joint 1, an upper oil inlet valve cover 4, a middle oil outlet valve cover 17, and a lower oil outlet valve cover 22, and the upper joint 1 is threaded to connect the upper oil inlet valve cover 4. The upper oil inlet valve seat 7 is built in the ring hole in the lower part of the upper oil inlet valve cover 4, and the upper part of the upper oil inlet valve seat 7 is positioned against the inner shoulder of the upper oil inlet valve cover 4 hole, and the upper oil inlet valve cover 4 is positioned. The lower end screw is connected with the upper oil inlet valve seat pressure cap 8, and the upper oil inlet valve seat pressure cap 8 is abutted on the upper oil inlet valve seat 7, and the upper oil inlet valve seat 7 top is provided with an upper oil inlet valve ball 6; The outer screw at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com