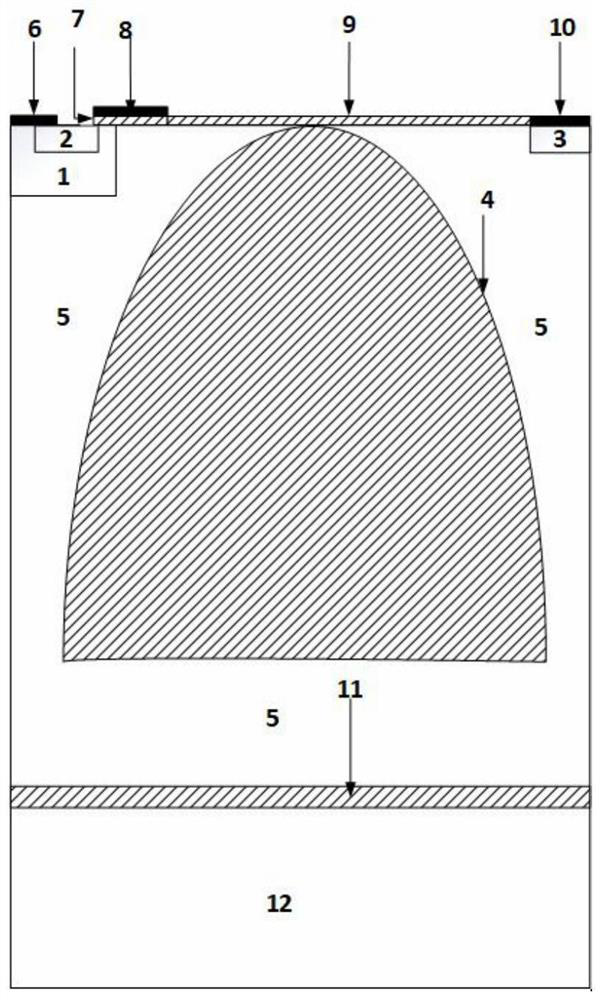

A semi-elliptical oxide trench ldmos transistor

A semi-ellipse, transistor technology, applied in the field of lateral double-diffused metal-oxide-semiconductor transistors, can solve the problems of extending the on-resistance of the conductive channel, reducing the on-resistance, etc., and achieving the improvement of on-resistance, performance improvement, and breakdown voltage increase Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

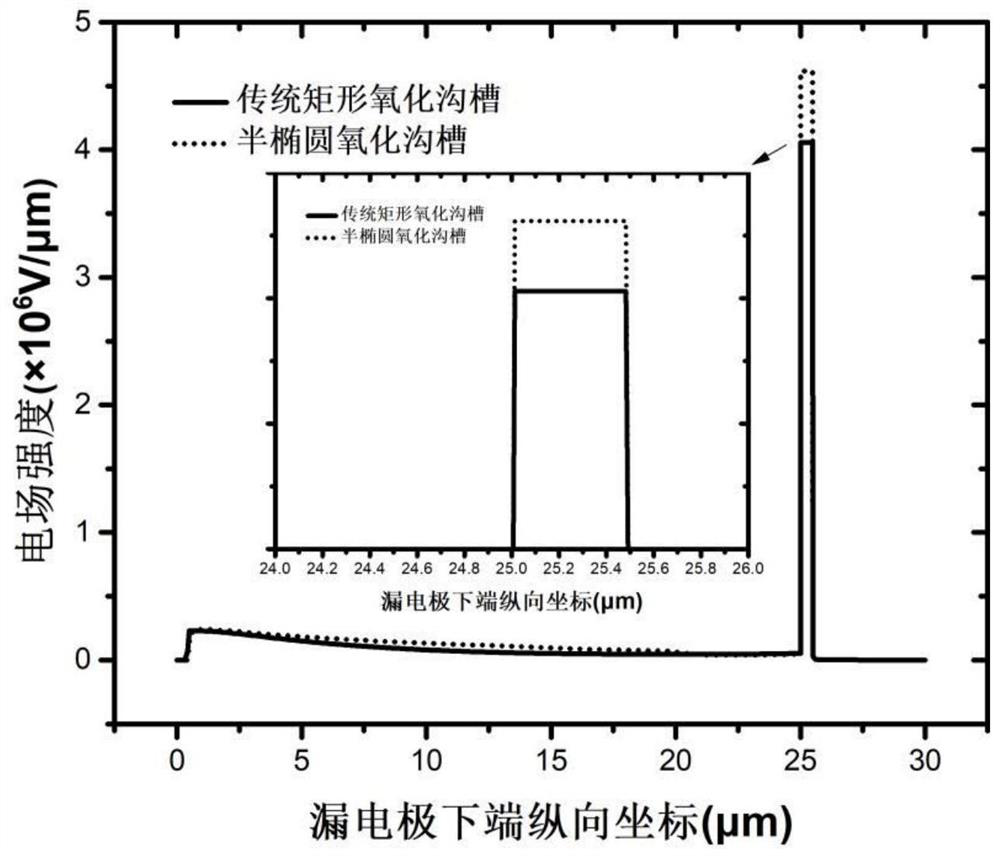

[0032] Parameter analysis example 2: change b, and change the doping concentration of the drift region;

[0033] Such as Figure 6 Shown is the effect of b on the relationship between device breakdown voltage and drift region doping concentration. It can be seen that for any curve, the breakdown voltage first increases and then decreases with the increase of the doping concentration in the drift region. For the whole family of curves, when the thickness a of the oxidation trench 4 is fixed, the maximum breakdown voltage of the curve increases with the increase of b, and the concentration of the drift region corresponding to the maximum breakdown voltage first increases and then Decrease, where b=7.4 is the inflection point. On the one hand, due to the limitation of the structure itself, b must be less than 8, so the maximum breakdown voltage will not increase infinitely; on the other hand, since the on-resistance needs to be as small as possible, that is, the greater the dop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com