Dust removal device for stone crushing and sand making discharging

A dust removal device and stone crushing technology, which is applied in the direction of dust removal, grain treatment, and separation of dispersed particles, can solve the problems of dust flying, finished sand powder and needle flakes exceeding the standard, and affecting the quality of concrete strength and infrastructure projects. health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

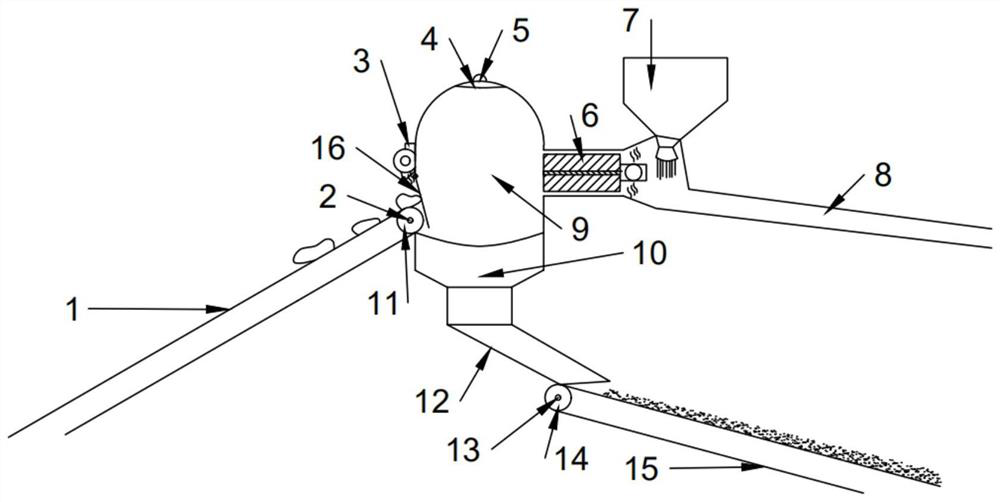

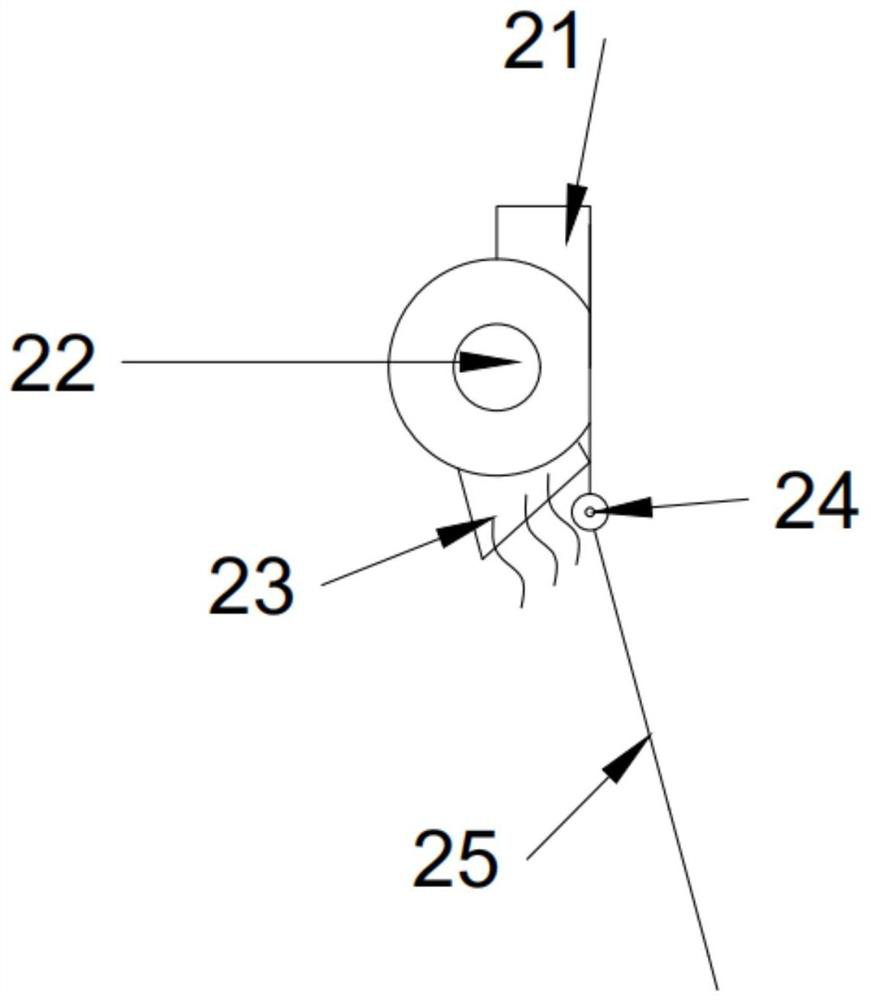

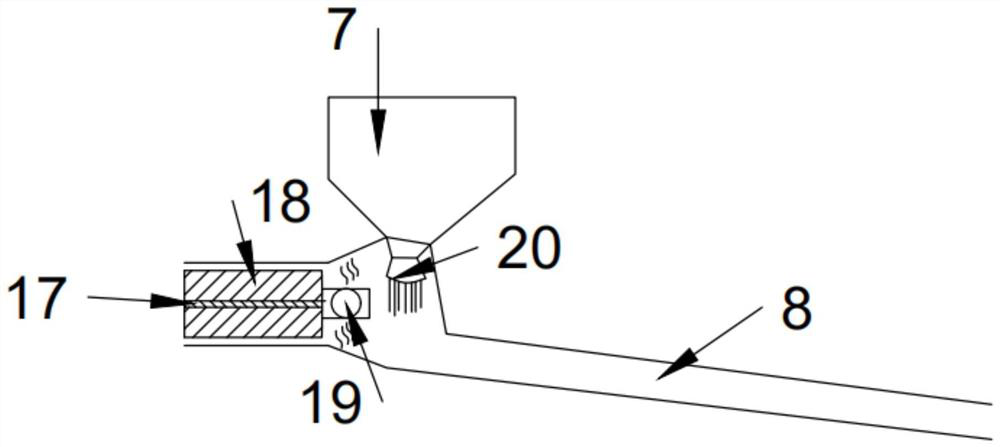

[0022] see figure 1 , the present embodiment provides a kind of dedusting device for gravel sand making and discharging, comprising a stone conveyor belt 1, a stone conveying wheel shaft 2, a gravel sand making tank 9, a gravel working layer 10, a stone conveying wheel 11, and a lower discharge port 12. Sand conveyor wheel shaft 13, sand conveyor wheel 14, and sand conveyor belt 15; the stone conveyor belt 1 tightly wraps the surface of the stone conveyor wheel 11, and the stone conveyor wheel 11 is installed and fixed on the stone conveyor wheel shaft 2. The lower part of the sand tank 9 is provided with a gravel operation layer 10, and the gravel operation layer is fixedly connected with a lower outlet 12, and the bottom of the lower outlet 12 is closely connected to the sand conveyor belt 15, and the sand conveyor belt 15 is tightly wrapped in the sand conveyor. Wheel 14 surface, abrasive material transmission wheel 14 is installed and fixed on the abrasive material transmi...

Embodiment 2

[0026] On the basis of Embodiment 1, there are two centrifugal vacuum cleaners 6, and the left and right positions are aligned and symmetrically distributed on the rear wall of the gravel sand making tank 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com