Slitting device of water permeable brick production line and using method thereof

A technology of permeable bricks and production lines, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of troublesome and laborious operation, poor cutting quality, etc., and achieve the effect of reducing labor intensity, improving work efficiency, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

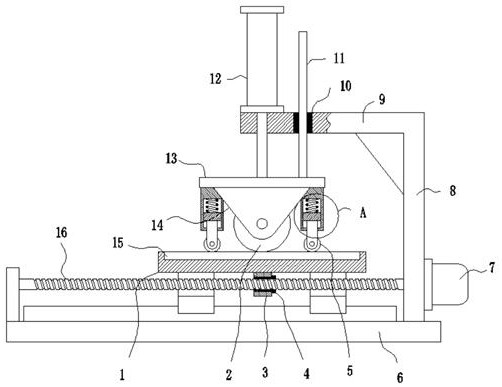

[0030] Such as Figure 1-2 As shown, a cutting device of a permeable brick production line includes:

[0031] Base 6;

[0032] Sliding positioning seat 1, the sliding positioning seat 1 is horizontally slidably connected to the base 6, and its top is provided with a placement groove 15 in the form of a blind hole for external permeable bricks to be placed;

[0033] a translation drive assembly, which drives the sliding positioning seat 1 to slide horizontally along the length direction of the base 6;

[0034] A bracket assembly, the bracket assembly includes a vertical plate 8 arranged on one end of the base 6, the upper end of the vertical plate 8 is provided with a top plate 9;

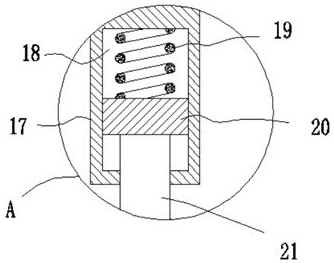

[0035] The cutter assembly, the cutter assembly includes a lifting cylinder 12 vertically installed on the support assembly top plate 9, the lifting cylinder 12 is driven and connected with a lifting plate 13, and the bottom of the lifting plate 13 is provided with a mounting seat 14, so The moun...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap