A method for strengthening and protecting open-air masonry cultural relics based on nanocomposite materials

A technology for nano-composite materials and cultural relics, which is applied in the field of cultural relics protection materials, can solve the problems of few types of applicable substrates, many types of raw materials, and high cost, and achieves the effects of simple preparation and use methods, excellent permeability, and few raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1, using nano-SiO 2 Pre-consolidation of stone samples with aqueous dispersions

[0037] 1.1 Weigh 2.00g of nano-SiO with a particle size of 10nm respectively 2 , measure 24.67ml of deionized water, use an ultrasonic disperser to evenly disperse the nanoparticles into deionized water, and configure a pre-reinforcement agent with a concentration of 7.5%;

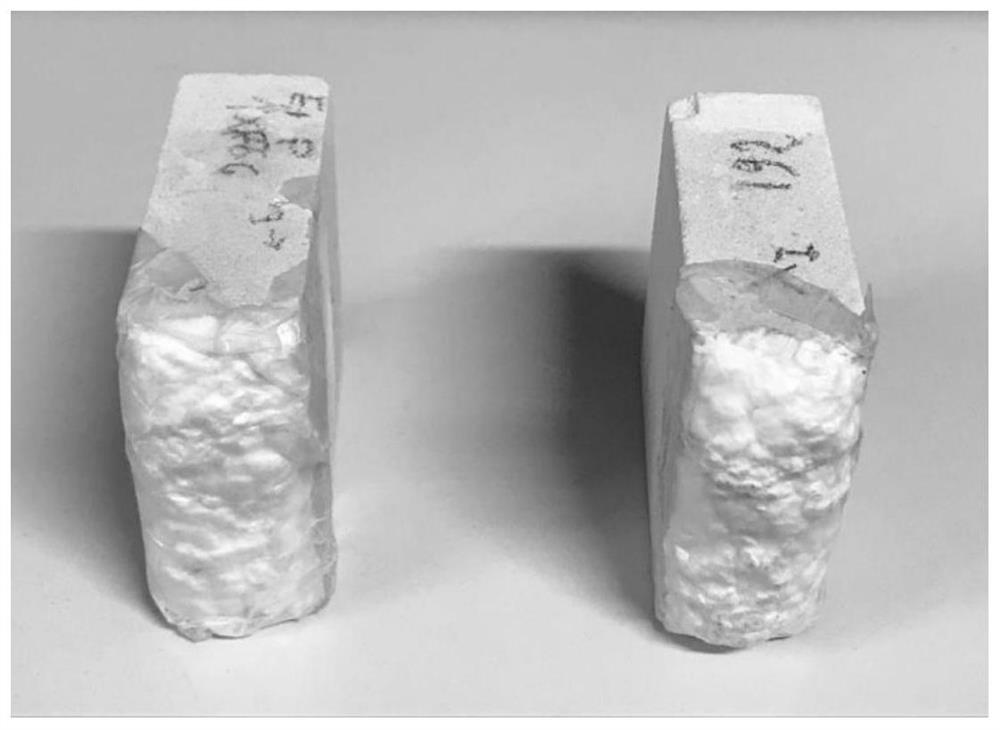

[0038]1.2 Weigh 2.00g of flocculent cellulose, and evenly cover the cellulose on the surface of the Italian Leccese (Pietra Leccese, limestone, 35-47% porosity) sample surface with a surface area of 5 × 2 square centimeters, and then use pipetting The tube will be configured with nano-SiO 2 The dispersion is added dropwise to the powder, which is then wrapped with Parafilm. When the powder is gradually dry, open the sealing film and then dropwise add nano-SiO 2 Dispersions. This step continued for 8 hours until all of the formulated dispersion was used up.

[0039] Step 2. Reinforce the stone sample with a...

Embodiment 2

[0044] Step 1, using nano-SiO 2 The water-based dispersion liquid pre-reinforces the stone sample, and the specific material dosage and operation method are the same as those in Example 1.

[0045] Step 2. Reinforce the stone sample with a mixture of tetraethylorthosilicate and Silo 112

[0046] 2.10 g of tetraethyl orthosilicate and 0.900 g of Silo 112 were weighed and mixed in a beaker, stirred evenly, and configured as a mixed reinforcement liquid with a mass percentage of 70%:30%. After removing the flocculent cellulose powder paste, the mixture was directly added dropwise to the surface of the sample using a pipette, and the reinforcement solution was added every 5 minutes. This step was continued until the reinforcement agent was used up.

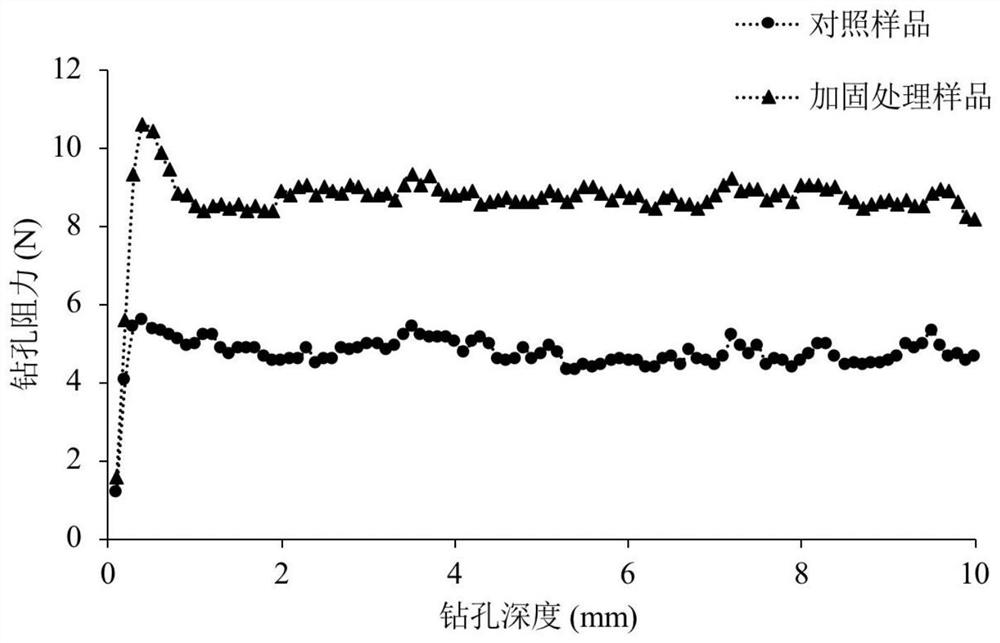

[0047] The reinforced samples were placed in a laboratory environment for 30 days and then tested according to EU standard test methods. Drilling tests were carried out on the samples, and the results showed that the mechanical stre...

Embodiment 3

[0049] Step 1, using nano-SiO 2 The water-based dispersion liquid pre-reinforces the stone sample, and the specific material dosage and operation method are the same as those in Example 1.

[0050] Step 2. Reinforce the stone sample with a mixture of tetraethylorthosilicate and Silo 112

[0051] 1.43 g of tetraethyl orthosilicate and 0.075 g of Silo 112 were weighed and mixed in a beaker, stirred evenly, and configured as a mixed reinforcement liquid with a mass percentage of 95%:5%. After removing the flocculent cellulose powder paste, the mixture was directly added dropwise to the surface of the sample using a pipette, and the reinforcement solution was added every 4 minutes. This step was continued until the reinforcement agent was used up.

[0052] The reinforced samples were placed in a laboratory environment for 30 days and then tested according to EU standard test methods. Drilling tests were carried out on the samples, and the results showed that the mechanical stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com