Forming mold for alcohol-based solid fuel production

A technology of solid fuel and forming molds, which is applied in the direction of solid fuel, fuel, waste fuel, etc., can solve the problems of large skin damage of human hands, cold and biting hand, easy to cause injury to human body, and occupational diseases, so as to reduce the possibility of occupational diseases Sex, reduce human resource input, and reduce the effect of human body impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

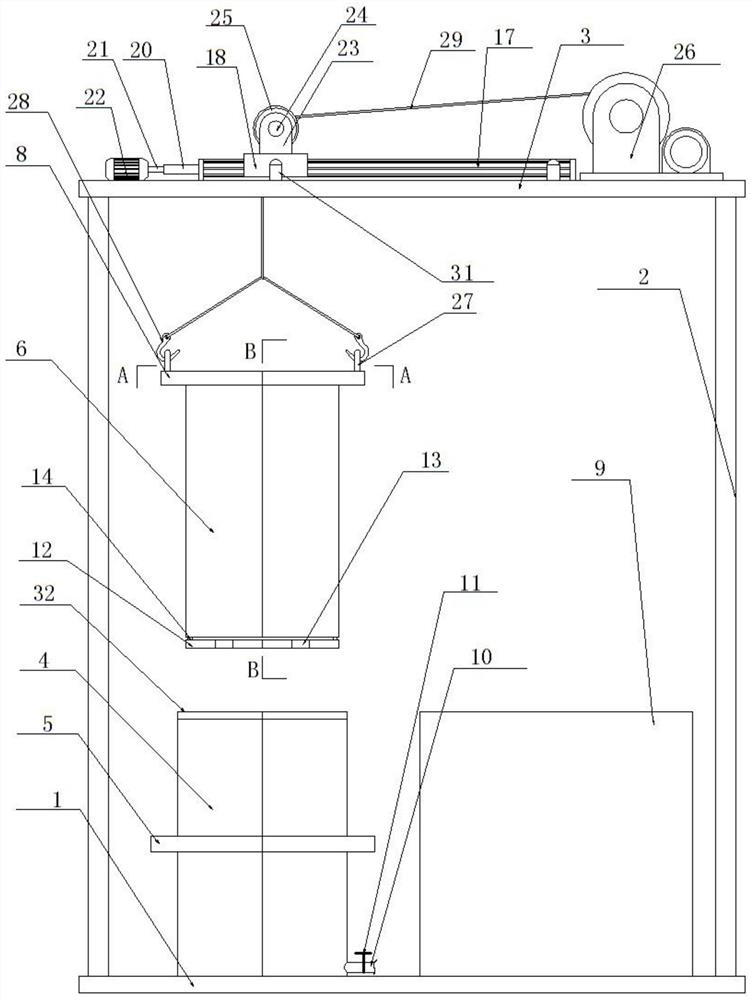

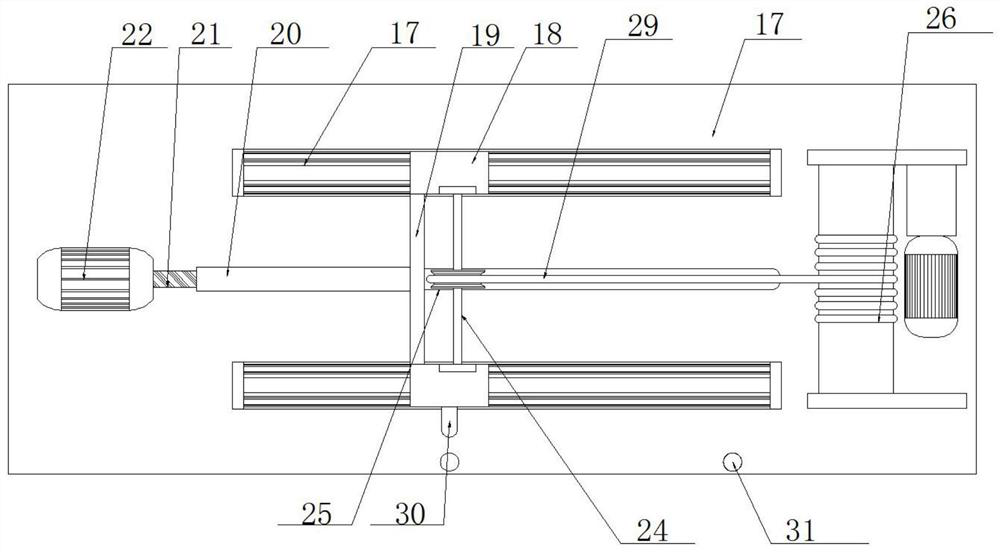

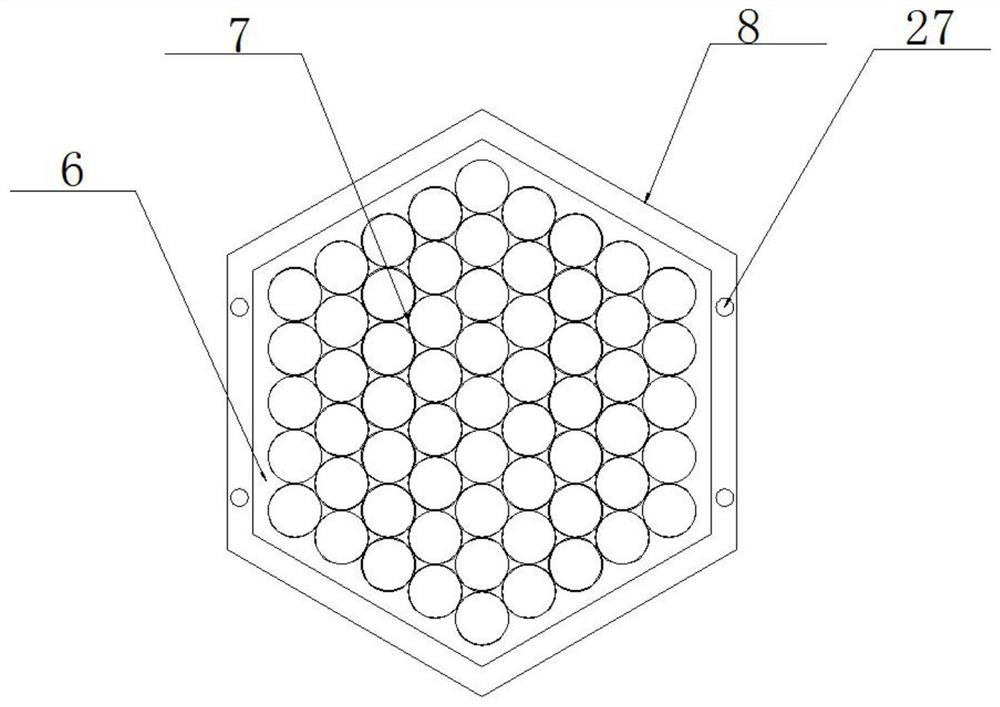

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] see as Figure 1-Figure 7As shown, the technical solution adopted in this specific embodiment is: it includes base plate 1, support rod 2, top plate 3, inner barrel 6, outer barrel 4, stainless steel pipe 7, No. 1 reinforcing rib 5 and No. 2 reinforcing rib 8; The four corners of the top surface are vertically fixedly welded with support rods 2, and the upper ends of the support rods 2 are fixedly welded on the bottom surface of the top plate 3; Hollow structure with opening on the upper side, fixed welding hoops on the surrounding walls of the outer barrel 4 are provided with a No. 1 reinforcing rib 5, the upper side of the outer barrel 4 is movably inserted with an inner barrel 6, and the inner barrel 6 and the outer barrel 4 are a matching hexagonal column structure , the top surface of the outer barrel 4 is fixed with a rubber washer 32 by bolts, and the ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com