Modular redundancy control device for electric control system of integrated sewage pump station

An electrical control system, redundant control technology, applied in pump control, waterway system, water supply device, etc., can solve problems such as system inoperability and poor system reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

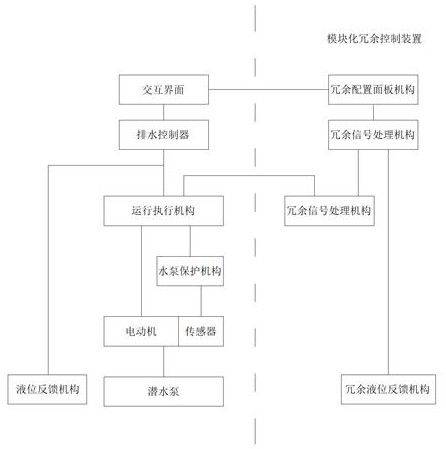

[0047]A modular redundant control device for the electrical control system of an integrated sewage pumping station, including a redundant signal processing mechanism, a redundant liquid level feedback mechanism, a redundant configuration panel mechanism, and a redundant signal output mechanism. The remaining liquid level feedback mechanism is used to collect liquid level signals and is connected to the redundant signal processing mechanism; the redundant configuration panel mechanism is used to collect water pump setting information and is connected to the redundant signal processing mechanism; the redundant The signal output mechanism is connected with the redundant signal processing mechanism to transmit redundant start and stop pump commands.

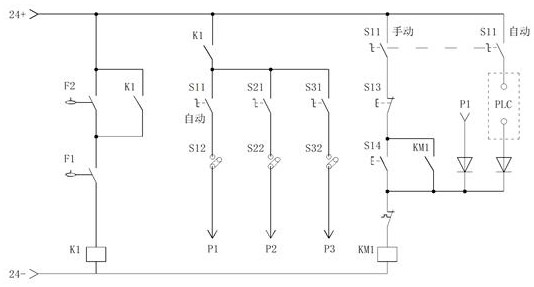

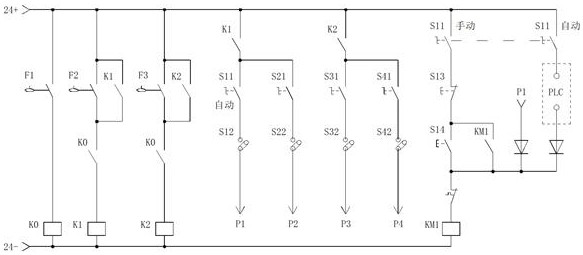

[0048] The hardware of the main institutions includes:

[0049] The hardware structure of the redundant signal processing mechanism can be simply composed of intermediate relays to form a logical interlock circuit, or can be composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com