Variable-frequency refrigerating system and control method thereof

A refrigeration system and controller technology, which is applied to refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of low temperature control of variable frequency refrigeration systems, and achieve the effect of simple structure and improved operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

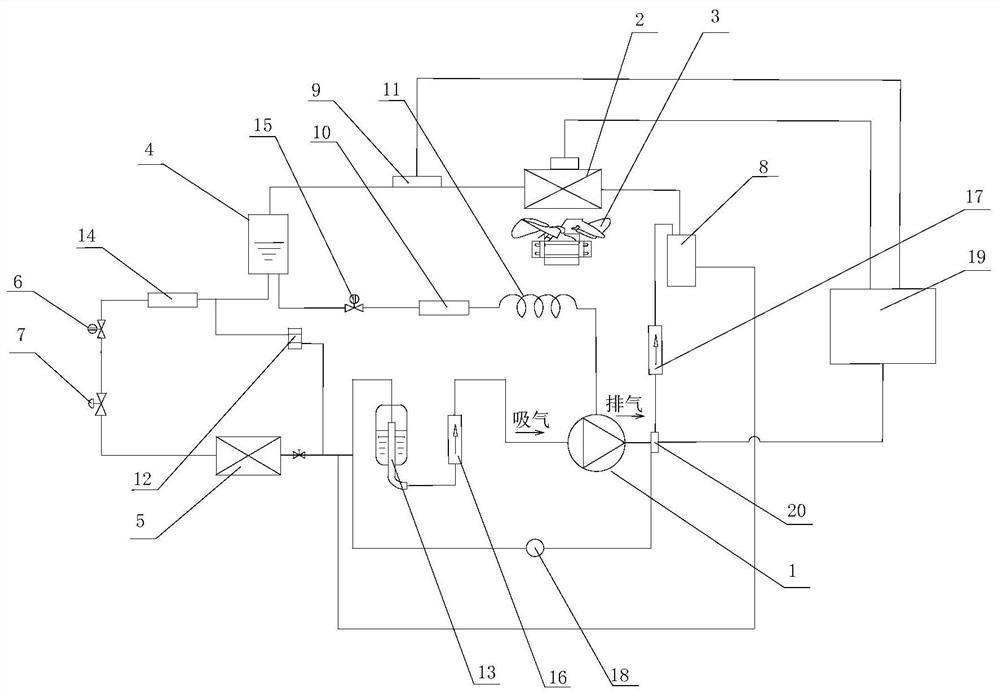

[0064] like figure 1 As shown, this embodiment provides a frequency conversion refrigeration system, including a compressor 1, a condenser 2, a condensing fan 3, a liquid storage tank 4, and an evaporator 5 connected in sequence, and the connection between the condenser 2 and the liquid storage tank 4 A condensation temperature sensor 9 is arranged on the pipeline, the high-pressure outlet of the compressor 1 is connected to the condenser 2, an exhaust temperature sensor 20 is arranged at the high-pressure outlet of the compressor 1, and a low-pressure outlet of the compressor 1 It is connected to the outlet of the evaporator 5, and also includes a solenoid valve 6, an electronic expansion valve 7, an oil separator 8 and a controller 19. The solenoid valve 6 and the electronic expansion valve 7 are sequentially arranged at the outlet of the liquid storage tank 4 and the evaporator 5 On the pipeline between the inlets, the oil separator 8 is arranged on the pipeline between the...

Embodiment 2

[0067] Embodiment 2 is to carry out further optimization on the basis of embodiment 1, and specific implementation scheme is as follows:

[0068] like figure 1 As shown, this embodiment provides a frequency conversion refrigeration system, including a compressor 1, a condenser 2, a condensing fan 3, a liquid storage tank 4, and an evaporator 5 connected in sequence, and the connection between the condenser 2 and the liquid storage tank 4 A condensation temperature sensor 9 is arranged on the pipeline, the high-pressure outlet of the compressor 1 is connected to the condenser 2, an exhaust temperature sensor 20 is arranged at the high-pressure outlet of the compressor 1, and a low-pressure outlet of the compressor 1 It is connected to the outlet of the evaporator 5, and also includes a solenoid valve 6, an electronic expansion valve 7, an oil separator 8 and a controller 19. The solenoid valve 6 and the electronic expansion valve 7 are sequentially arranged at the outlet of the...

Embodiment 3

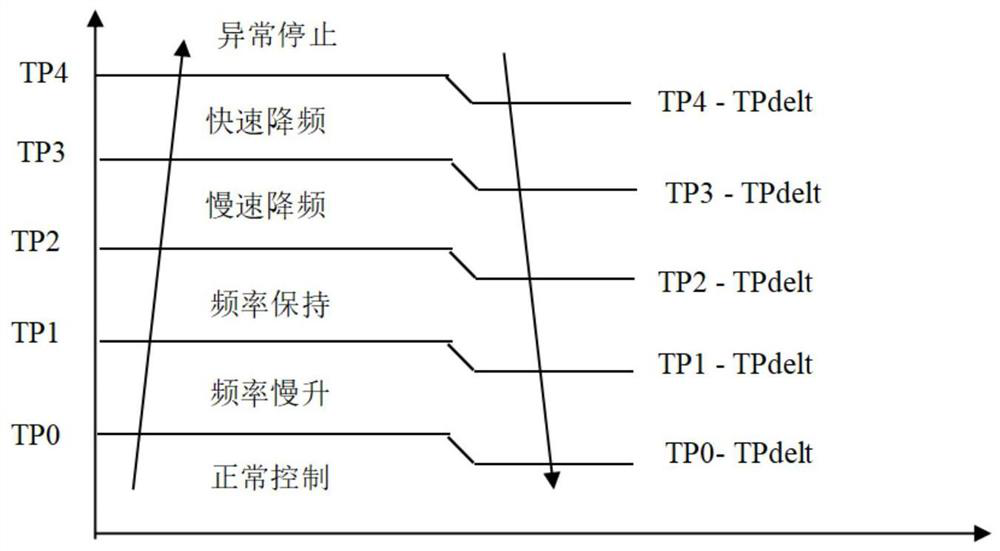

[0071] like Figure 1-3 As shown, this embodiment provides an intelligent control method for a frequency conversion refrigeration system. According to any one of the technical solutions of Embodiment 1-2, a frequency conversion refrigeration system includes:

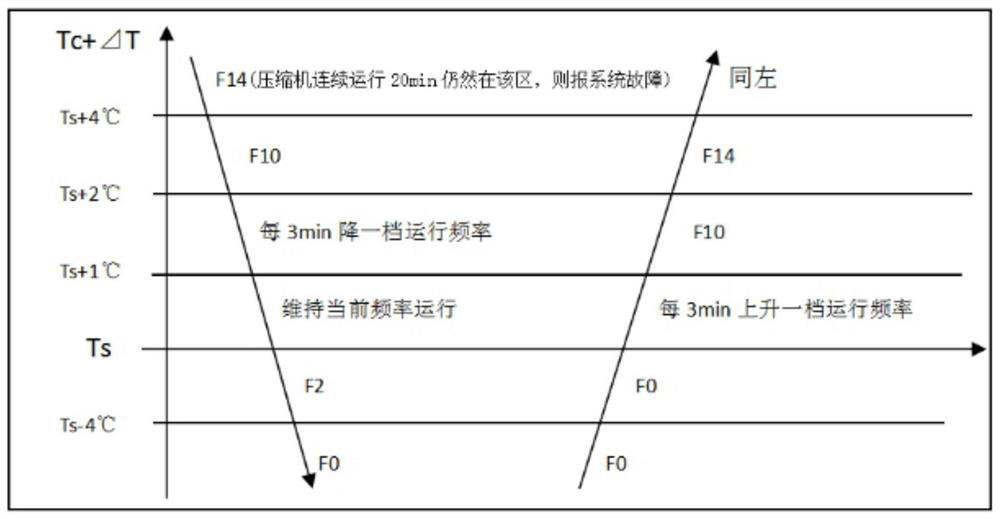

[0072] like figure 2 As shown, the compressor operating frequency control:

[0073] (1) The controller 19 controls, records, and reads the temperature in the cabinet (Tc) and the set temperature (Ts) in the cabinet, and the difference between the temperature in the cabinet (Tc) and the set temperature (Ts) in the cabinet is the temperature difference, the temperature range in the cabinet is -10℃~10℃;

[0074] (2) The operating frequency of the compressor 1 is controlled by the controller 19, and the operating frequency range of the compressor 1 is divided into 14 frequency segments, respectively marked as X1, X2, X3, X4, X5, X6, X7 , X8, X9, X10, X11, X12, X13, X14, each frequency value is read into the EEPROM, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com