Microwave vacuum-hot air sectional type drying method for pseudo-ginseng

A microwave vacuum drying and microwave vacuum technology is applied in the direction of drying solid materials with heating, drying solid materials without heating, drying solid materials, etc. Loss of active ingredients, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

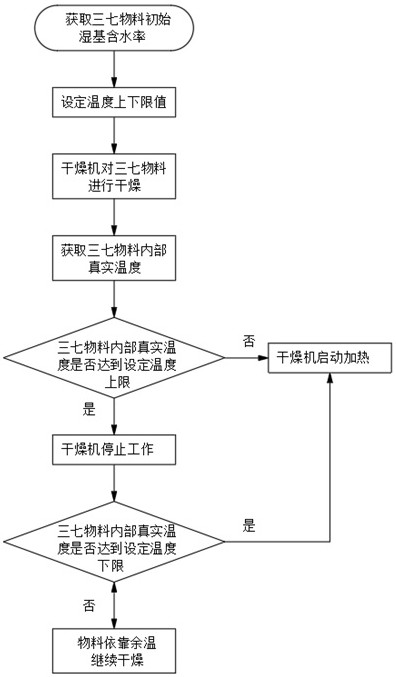

Method used

Image

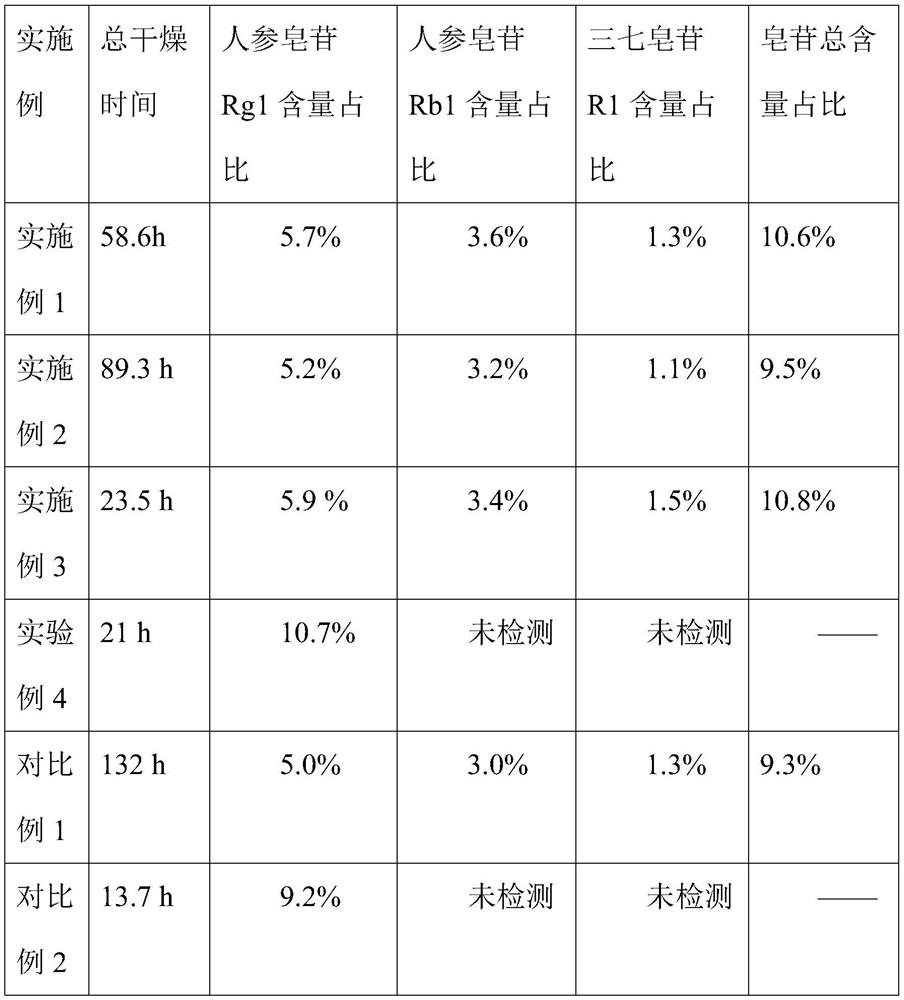

Examples

Embodiment 1

[0027] A kind of notoginseng microwave vacuum-hot air section drying method, comprises the following steps:

[0028] (1) Preparatory work for Sanqi drying: select newly harvested three-year-old Panax notoginseng, wash it clean, and drain the surface water, classify Sanqi according to main root, notch, lateral root and fibrous root, and select the main root of Panax notoginseng .

[0029] (2) Weigh 30±1g of the main root, cut it into thin slices, put it in an oven with a set temperature of 80°C, dry it for 24 hours until it is completely dry, take out the Panax notoginseng thin slice and weigh it again, and calculate the moisture content on a wet basis 61.24%.

[0030] (3) Microwave vacuum drying: Weigh 100 ± 0.5g fresh Panax notoginseng taproot, put it on the material tray of the dryer, insert the fluorescent optical fiber temperature sensor probe into a Panax notoginseng taproot, close the dryer door; adjust the intake valve, set Set the absolute vacuum degree to 5kPa; adju...

Embodiment 2

[0035] A method for notoginseng microwave vacuum-hot air segmental drying, comprising the following steps:

[0036] Step (1) is identical with embodiment 1.

[0037]Step (2) is the same as in Example 1, and the calculated moisture content on a wet basis is 61.24%.

[0038] Step (3) is identical with embodiment 1, and microwave power is 100W, and this moment power density is 1W / g, and upper and lower limit of temperature value is 55,45 ℃, and absolute vacuum degree is 5kPa, and conversion wet basis moisture content is 30%.

[0039] (4) Weigh the main root of Panax notoginseng, and calculate the moisture content of the wet basis. When the moisture content of the main root of Panax notoginseng drops to 30±0.5% of the converted wet basis, the drying time is 10.3 hours. Turn off the microwave vacuum dryer, take out the main root of Panax notoginseng, and put it in an oven to continue drying.

[0040] (5) Hot air drying: set the oven temperature at 55°C and the wind speed at 0.5m / ...

Embodiment 3

[0042] A method for microwave vacuum-hot air segmental drying of Panax notoginseng main root, comprising the following steps:

[0043] Step (1) is identical with embodiment 1.

[0044] Step (2) is the same as in Example 1, and the calculated moisture content on a wet basis is 61.24%.

[0045] Step (3) is identical with embodiment 1, microwave power 100W, and this moment power density is 1W / g, and upper and lower limit of temperature value is 50, 40 ℃, and absolute vacuum is 1kPa, and conversion moisture content is 30%.

[0046] (4) Take the weight of the main root of Panax notoginseng, and calculate the moisture content of the wet basis. When the moisture content of the main root of Panax notoginseng drops to 30±0.5% of the converted wet basis, the drying time is 6.5 hours. Turn off the microwave vacuum dryer, take out the main root of Panax notoginseng, and put it in an oven to continue drying.

[0047] (5) Hot air drying: set the oven temperature at 55°C and the wind speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com