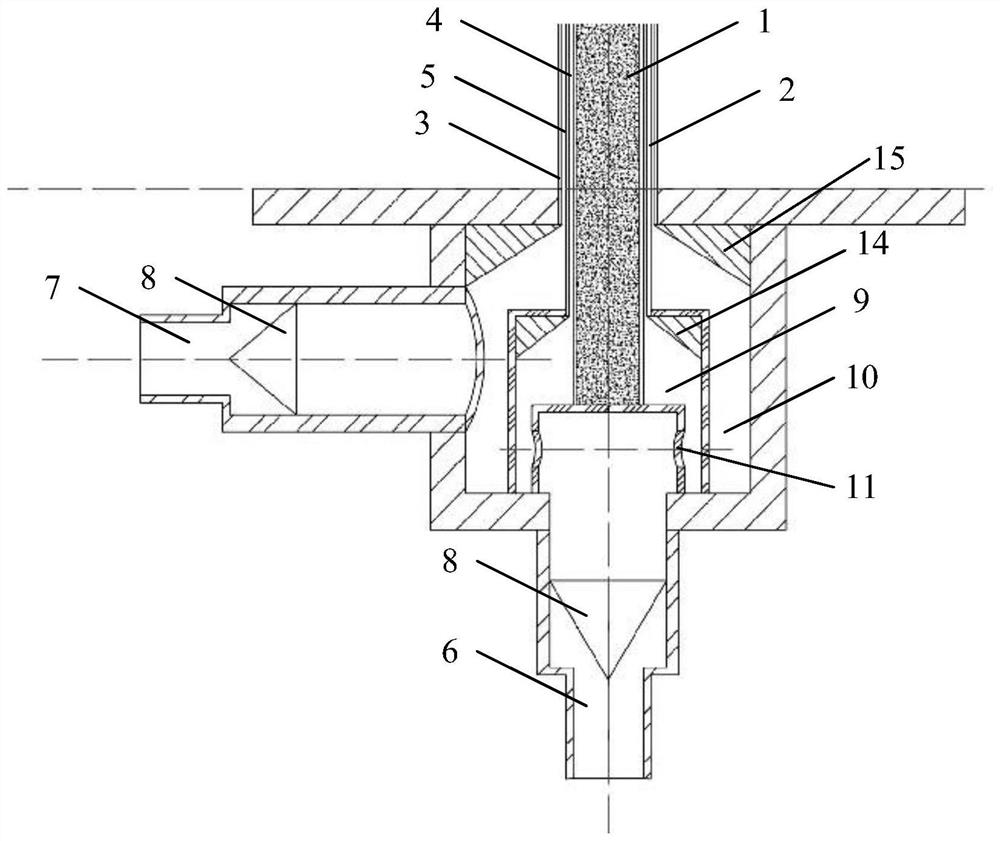

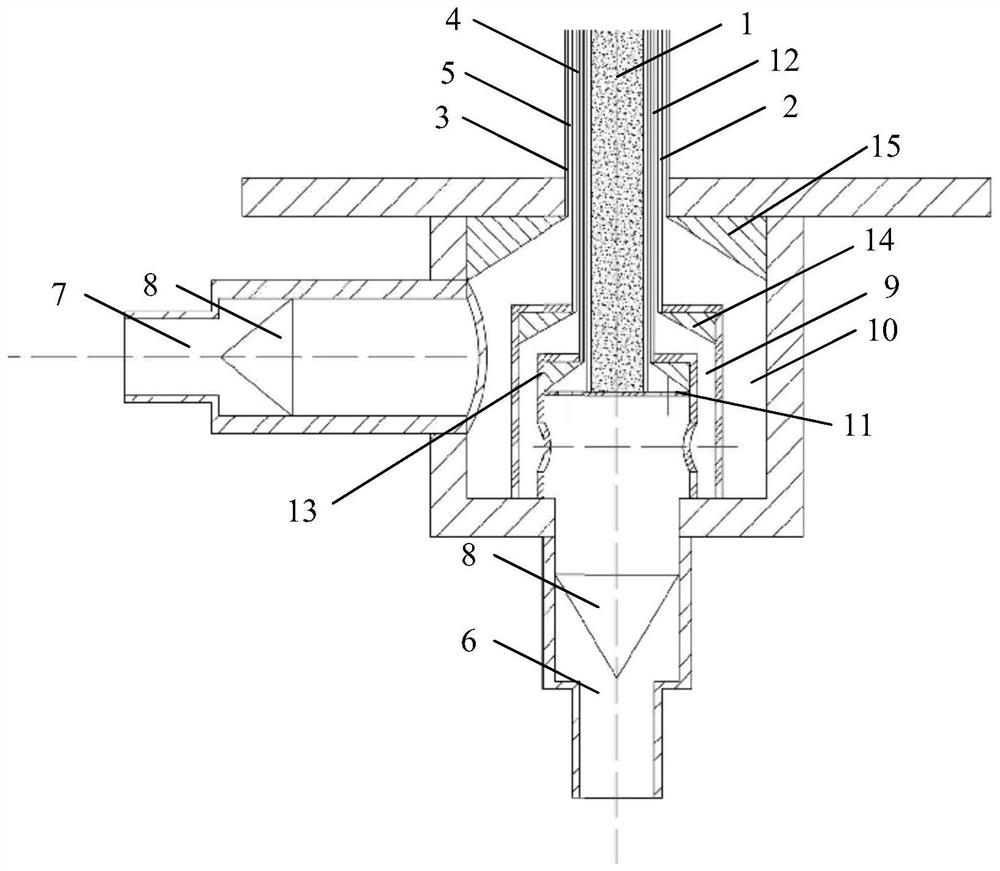

A circular seam type gas supply element and gas supply method

A technology of gas supply components and annular seams, which is applied in the field of metallurgy and can solve problems such as the inability to achieve high-intensity gas injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0082] This embodiment provides a gas supply method for an annular slit type gas supply element, including the following steps:

[0083] The inner gas is injected into the metal molten pool of the metallurgical furnace through the inner air chamber and the inner annular gap in turn;

[0084] And / or, the outer gas is injected into the metal molten pool of the metallurgical furnace through the outer air chamber and the outer annular gap in sequence;

[0085] The types of the inner gas and the outer gas are the same or different.

[0086] Compared with the prior art, the beneficial effects of the gas supply method of the annular-slit air supply element provided in this embodiment are basically the same as those of the annular-slit air supply element provided in Embodiment 1, and will not be repeated here.

[0087] From the perspective of protecting the furnace lining, in the above gas supply method, the gas flow rate outside the outer ring seam is smaller than the inner gas flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com