Magnetic particle flaw detector for blade detection

A magnetic particle inspection and blade technology, applied in the direction of material magnetic variables, etc., can solve the problems of inability to effectively detect the blade tip and tenon parts, small contact area, easy-to-burn parts, etc., and achieve high inspection efficiency, simple operation, and low labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

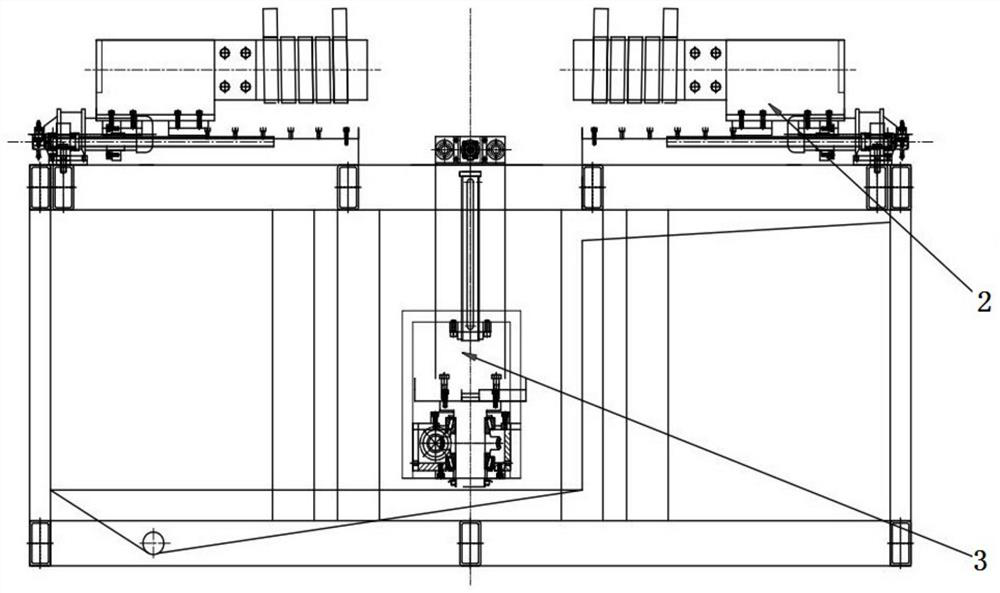

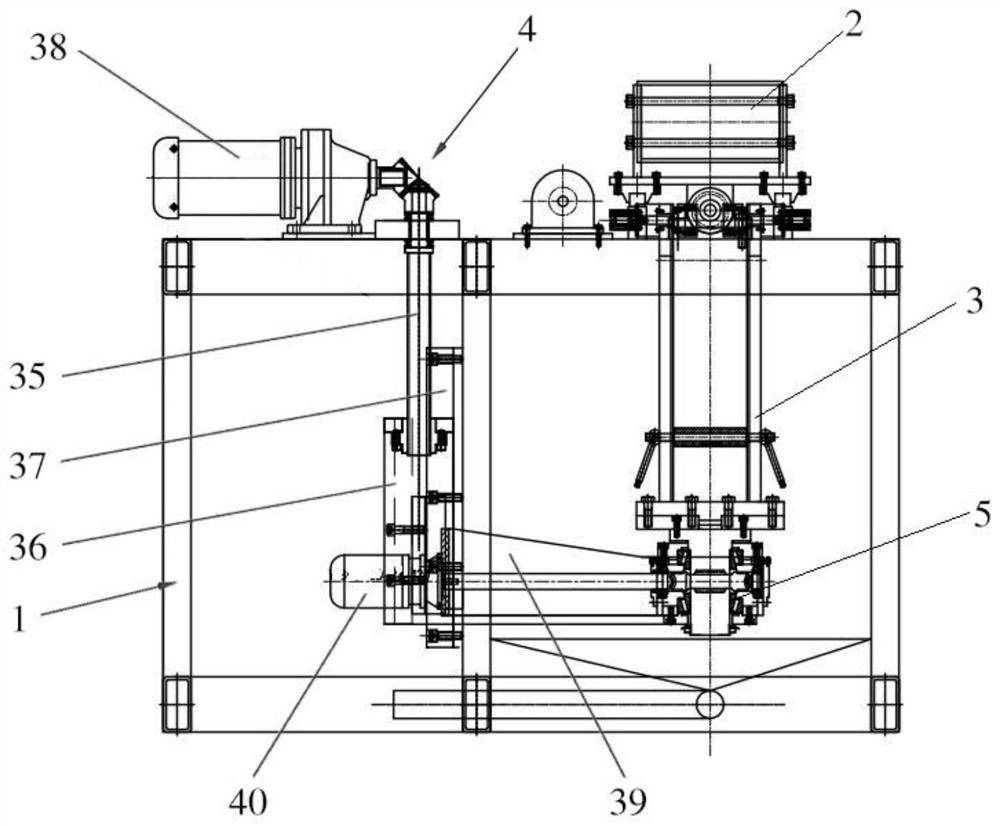

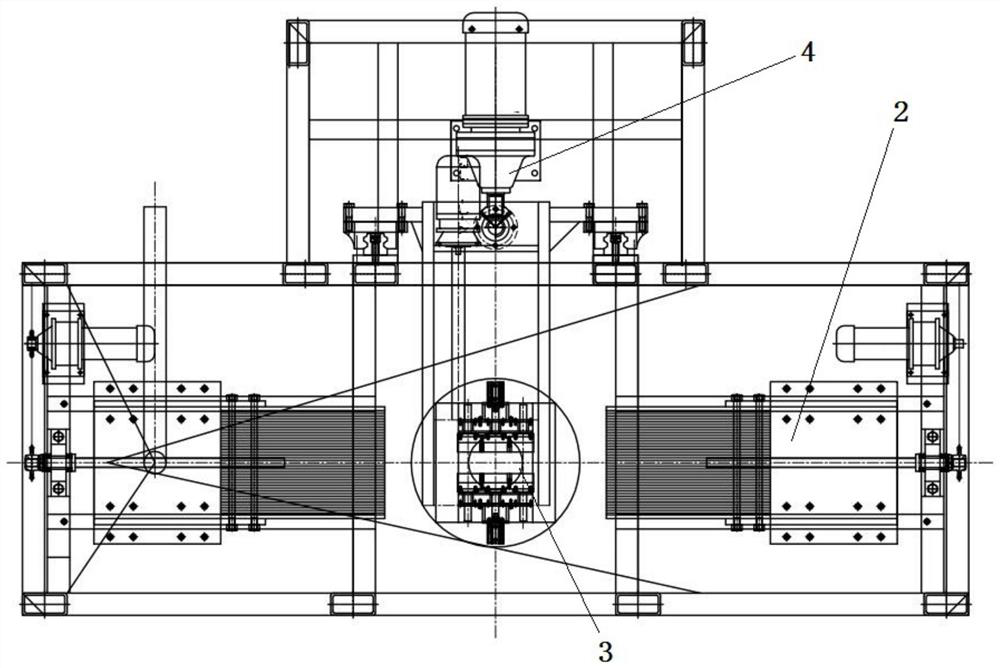

[0029] see Figures 1 to 7 As shown, the present embodiment provides a magnetic particle inspection machine for blade detection, which includes a frame 1 , a yoke assembly 2 , a lift drive mechanism 4 , a rotation drive mechanism 5 and a blade clamp mechanism 3 .

[0030] The two yokes 2 are oppositely arranged on the frame 1, and are used to act on the blades on both sides and magnetize the magnetic powder on the surface of the blades. The yoke part assembly 2 includes a yoke fixing frame 7, a horizontal guide rail 9, a T-shaped screw rod 11 and a reducer 16. The yoke fixing frame 7 is provided with a yoke assembly 8, and the bottom of the yoke fixing frame 7 is provided with a translation The slider 6 and two horizontal guide rails 9 are fixed on the frame 1 in parallel, the translation slider 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com