Nanoimprint device and method capable of preparing super-hydrophobic microstructure

A nano-imprinting and super-hydrophobic micro-technology, which is applied in the direction of photoplate-making process coating equipment, opto-mechanical equipment, pattern surface photoplate-making process, etc., can solve the problem of difficult to prepare composite structures, time-consuming, complicated preparation process, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

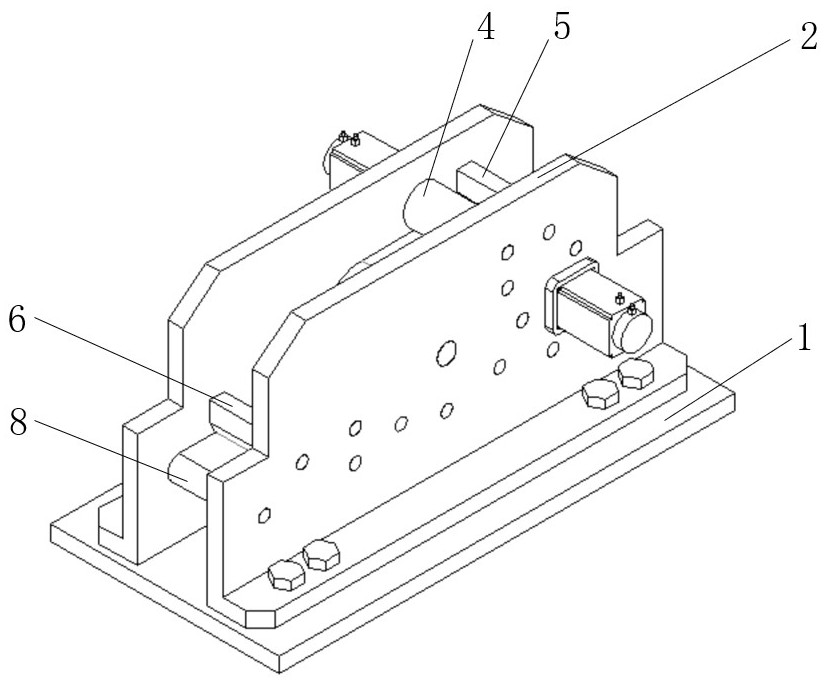

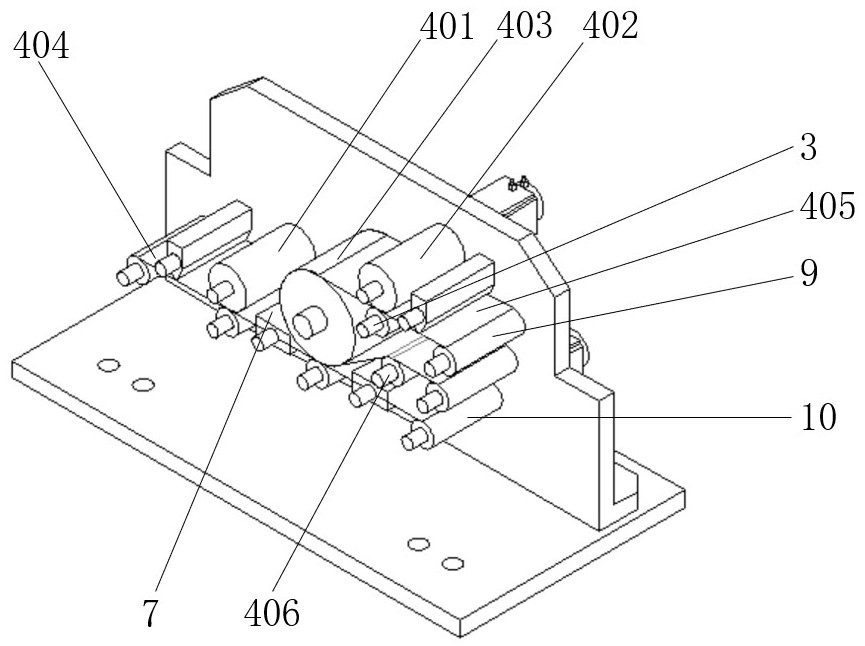

[0036] Such as figure 1 , figure 2As shown, the nanoimprinting device that can prepare superhydrophobic microstructures includes: frame 1, base plate 2, heating device 3, imprinting device 4, gluing device one 5, gluing device two 6, heat treatment Device 7, unwinding roller 1 8, unwinding roller 2 9, winding device 10, wherein the frame 1 is connected to the bottom plate 2 by screws, and the gluing device 1 5 and gluing device 2 6 are fixed on the frame by screws 1, the embossing device 4 is fitted on the frame 1 through bearings, the heating device 3 is fixed on the frame 1 by screws, the heat treatment device 7 is fixed on the frame 1 by screws, the unwinding roller 8, the unwinding roller Two 9 and the winding device 10 are all fitted on the frame 1 by bearings.

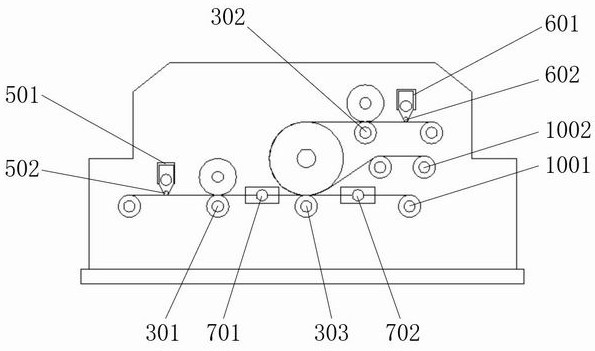

[0037] Such as image 3 As shown, the heating device 3 includes: a heating roller 1 301 , a heating roller 2 302 and a heating roller 3 303 , wherein the heating roller 1 301 , heating roller 2 302 and heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com