High-order backward-wave oscillation suppression structure for strip-shaped beam traveling-wave tube

A wave tube and high-order technology, which is applied in the field of high-order return wave oscillation suppression structure, can solve the problems of increasing the size of the slow wave structure, decreasing the gain of the whole tube, weakening the working mode, etc., so as to avoid the sharp decrease of the gain, reduce the distortion, The effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is further described:

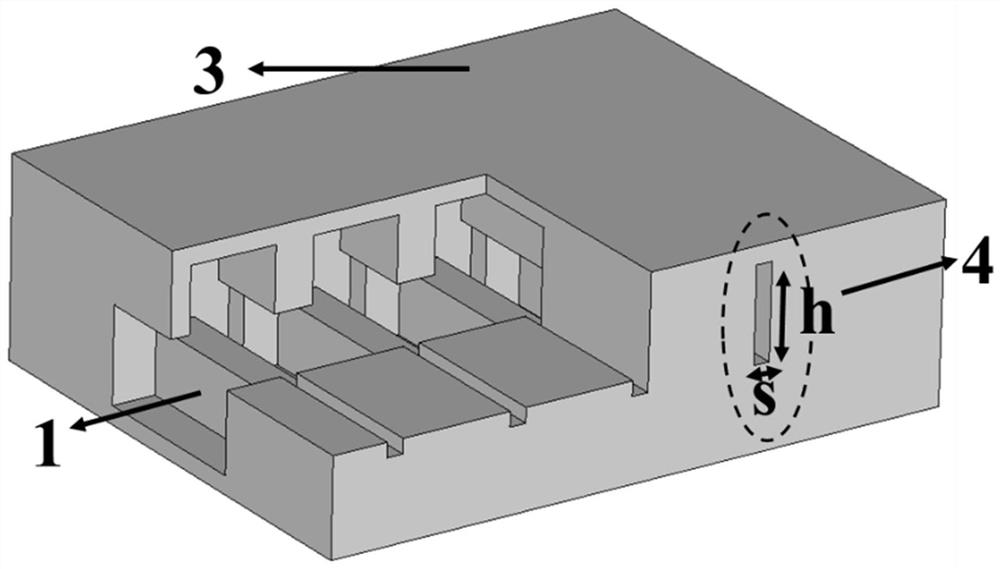

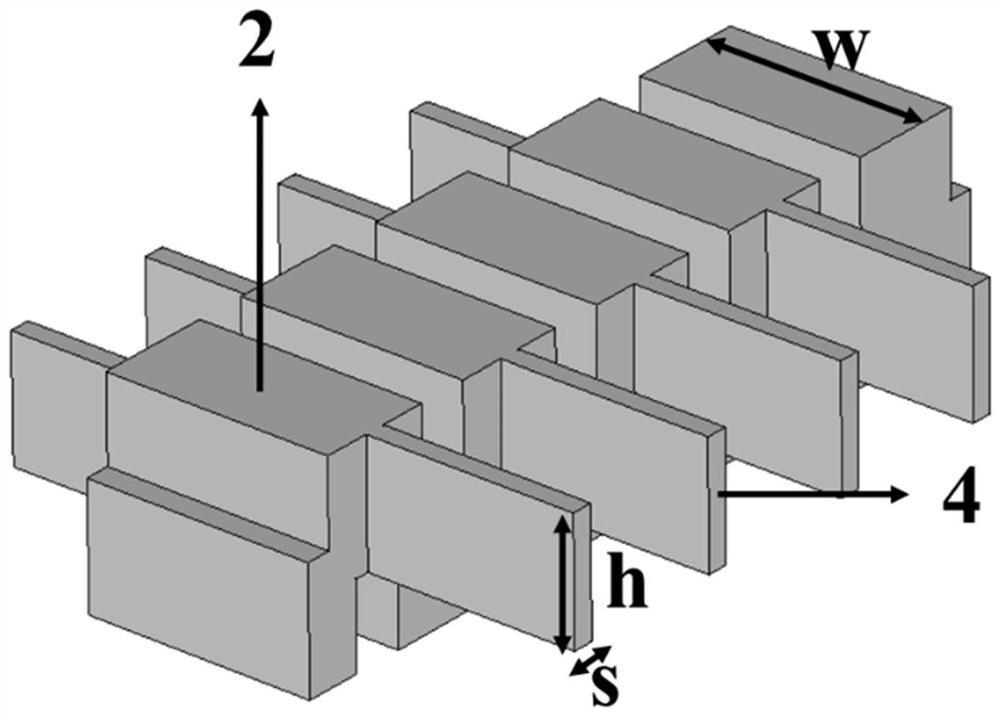

[0022] Refer to attached figure 2 , 3 , the present invention proposes a high-order back-wave oscillation suppression structure for a strip-shaped injection traveling wave tube. By loading interlaced rectangular coupling waveguides on both sides of the interlaced double-grid slow-wave structure, the structure realizes the suppression and absorption of high-order modes at the same time without destroying the working mode, effectively solving the problem of the strip injection traveling wave tube. Higher-order echo oscillations in the design.

[0023] The following is an example of a G-band strip traveling wave tube with a center frequency of 220GHz:

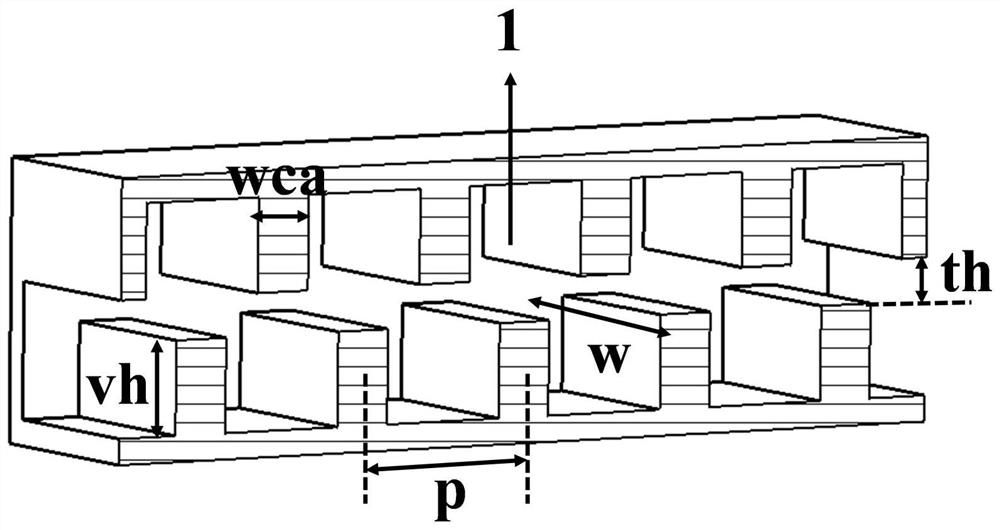

[0024] Such as figure 1 Shown is an interlaced double-grid slow-wave structure, metal grid height vh=0.33mm, grid width wca=0.2mm, grid length w=0.9mm, electron channel height th=0.15mm, period p=0.65mm. The interaction area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com