Method for preparing cathode additive for lithium secondary battery, and cathode additive for lithium secondary battery, prepared thereby

A lithium secondary battery and additive technology, applied in secondary batteries, electrode manufacturing, lithium storage batteries, etc., can solve the problems of high irreversible capacity loss, increased viscosity gelation of the composition, and difficulty in evenly coating the electrode composition. The effect of achieving excellent electrochemical and lifetime characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

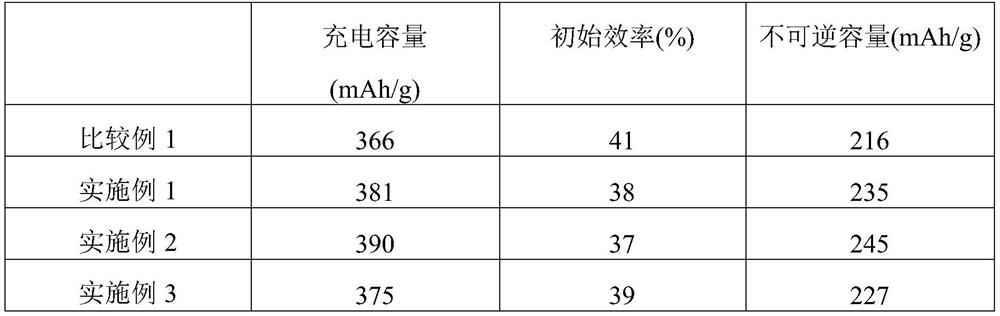

Examples

preparation example Construction

[0037] According to an embodiment of the present invention, a method for preparing a positive electrode additive for a lithium secondary battery is provided, which includes the following steps: mixing a lithium raw material, a nickel raw material, and an optional raw material containing an element M, and then heat-treating it to The lithium nickel oxide of the following chemical formula 1 was produced,

[0038] Wherein, the lithium raw material includes Li 2 O and LiOH, wherein, relative to the total weight of the lithium raw material, LiOH is used in an amount of 3 to 25% by weight, and wherein the positive electrode additive comprises the lithium nickel oxide:

[0039] [chemical formula 1]

[0040] Li 2 Ni 1-x m x o 2

[0041] In Chemical Formula 1,

[0042] M is selected from the group consisting of transition metals, amphoteric elements, P, F and B, wherein M is not nickel, and

[0043] 0≤x<1.

[0044] As a result of continuous research and experiments, the presen...

Embodiment 1

[0099] 14g of Li as a lithium raw material 2 O and 1 g of LiOH were mixed with 37 g of NiO as a nickel raw material, and then calcined at 700 °C for 15 h under a nitrogen atmosphere to obtain Li 2 NiO 2 positive electrode additive particles.

Embodiment 2

[0101] 13g of Li as a lithium raw material 2 O and 2 g of LiOH were mixed with 37 g of NiO as a nickel raw material, and then calcined at 700 °C for 15 h under a nitrogen atmosphere to obtain Li 2 NiO 2 positive electrode additive particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com