Dewatering and drying device for water-jet loom

A technology of drying device and loom, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of thermal denaturation of fabrics, product launch, unfavorable woven bag processing operations, etc., and achieve high quality and low thermal denaturation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

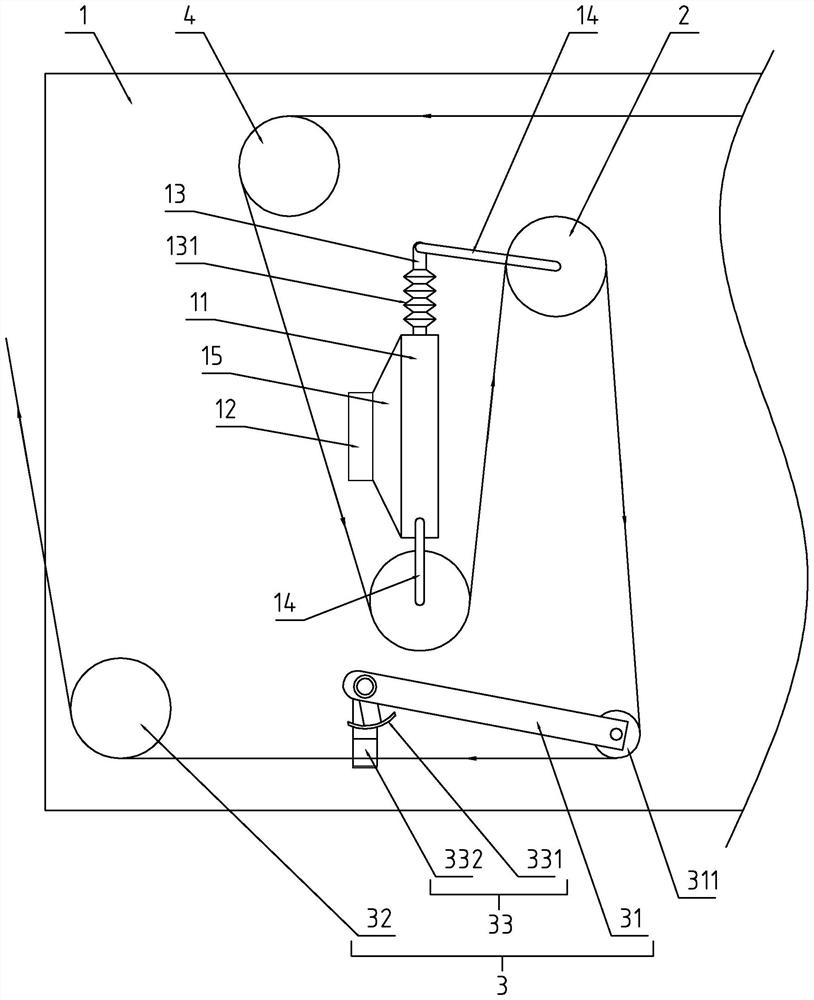

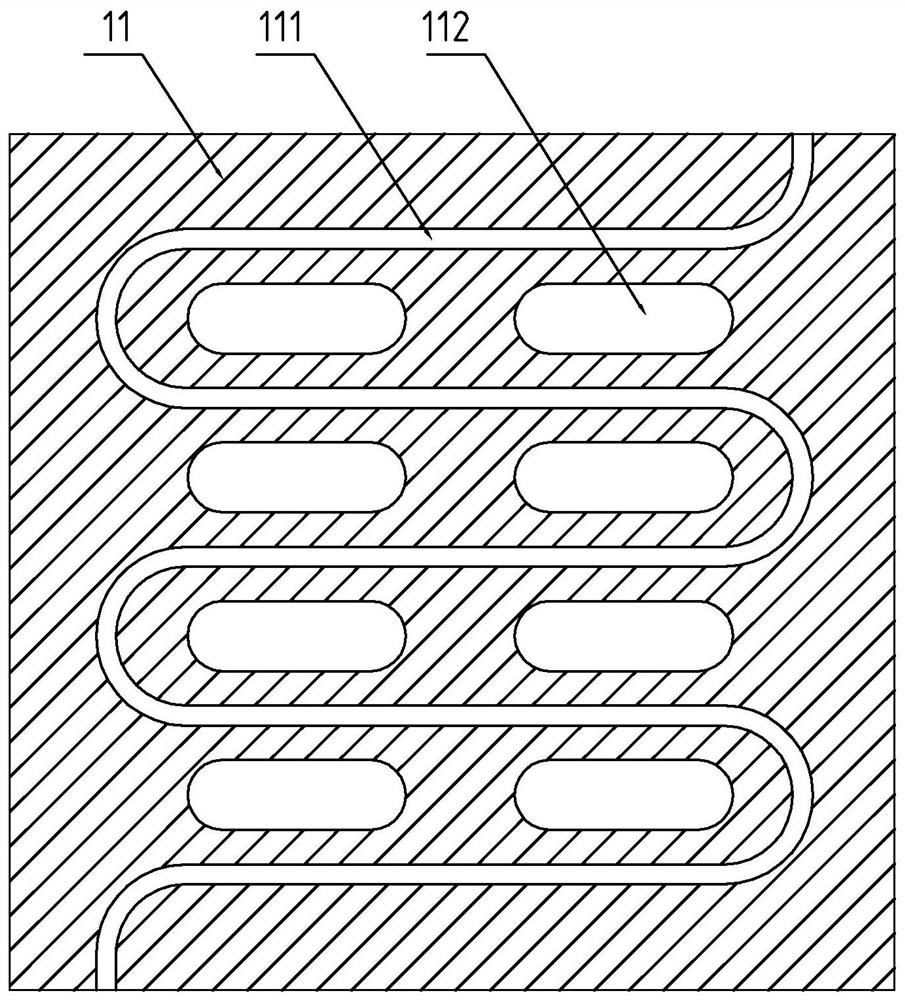

[0020] refer to Figure 1-3 As shown, a dehydration and drying device for a water jet loom includes a frame 1, and a feed wheel set and a discharge wheel set 2 that are rotatably connected to the frame 1, and are arranged on the frame 1 and are positioned at the feed wheel set. The weaving device between the material wheel group and the discharge wheel group 2, wherein the weaving device is a known technology, can refer to the existing design, the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com