Preparation method for high-stability fishing net inner thread

A high-stability, internal-line technology, applied in the direction of yarn, textiles, papermaking, fiber processing, etc., can solve the problems of weak market competitiveness and general performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

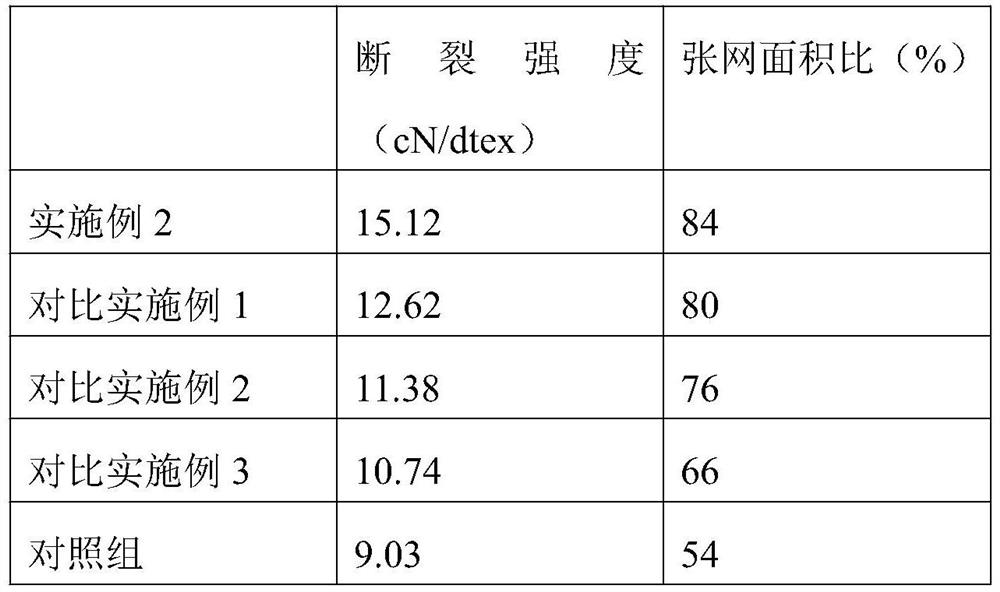

Examples

Embodiment 1

[0027] A method for preparing an inner thread of a high-stability fishing net, comprising the steps of:

[0028] (1) Preparation of inner fiber:

[0029] Immerse the acetate fiber and ramie fiber together in the acid solution, then comb them into separate strands, and finally blend and twist the strands to obtain the inner strand fibers for later use;

[0030] (2) Preparation of inner cable fiber paint:

[0031] Weigh the following materials according to the corresponding parts by weight: light calcium carbonate, asbestos powder, polyethylene, natural rubber, modified additives; then blend all the above materials evenly, and heat to a melted state to obtain the inner cable fiber coating agent for later use;

[0032] (3) Preparation of the inner line of the finished fishing net:

[0033] Suspend and draw the inner wire fiber prepared in step (1) in the inner wire mold, then inject the inner wire fiber coating agent prepared in step (2) into the inner wire mold, then heat and ...

Embodiment 2

[0047] A method for preparing an inner thread of a high-stability fishing net, comprising the steps of:

[0048] (1) Preparation of inner fiber:

[0049] Immerse the acetate fiber and ramie fiber together in the acid solution, then comb them into separate strands, and finally blend and twist the strands to obtain the inner strand fibers for later use;

[0050] (2) Preparation of inner cable fiber paint:

[0051] Weigh the following materials according to the corresponding parts by weight: light calcium carbonate, asbestos powder, polyethylene, natural rubber, modified additives; then blend all the above materials evenly, and heat to a melted state to obtain the inner cable fiber coating agent for later use;

[0052] (3) Preparation of the inner line of the finished fishing net:

[0053] Suspend and draw the inner wire fiber prepared in step (1) into the inner wire mold, then inject the inner wire fiber coating agent prepared in step (2) into the inner wire mold, then heat an...

Embodiment 3

[0067] A method for preparing an inner thread of a high-stability fishing net, comprising the steps of:

[0068] (1) Preparation of inner fiber:

[0069] Immerse the acetate fiber and ramie fiber together in the acid solution, then comb them into separate strands, and finally blend and twist the strands to obtain the inner strand fibers for later use;

[0070] (2) Preparation of inner cable fiber paint:

[0071] Weigh the following materials according to the corresponding parts by weight: light calcium carbonate, asbestos powder, polyethylene, natural rubber, modified additives; then blend all the above materials evenly, and heat to a melted state to obtain the inner cable fiber coating agent for later use;

[0072] (3) Preparation of the inner line of the finished fishing net:

[0073] Suspend and stretch the inner wire fiber prepared in step (1) in the inner wire mold, then inject the inner wire fiber coating agent prepared in step (2) into the inner wire mold, then heat a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com