Intelligent control system and method for energy efficiency of indirect evaporative cooling unit

An evaporative cooling unit technology, applied in the field of indirect evaporative cooling unit energy-efficiency intelligent control system, can solve problems such as difficult to achieve refrigeration and energy saving, high energy consumption of evaporative cooling unit, poor cooling effect of evaporative cooling unit, etc., to achieve energy saving effect, Good cooling effect and good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

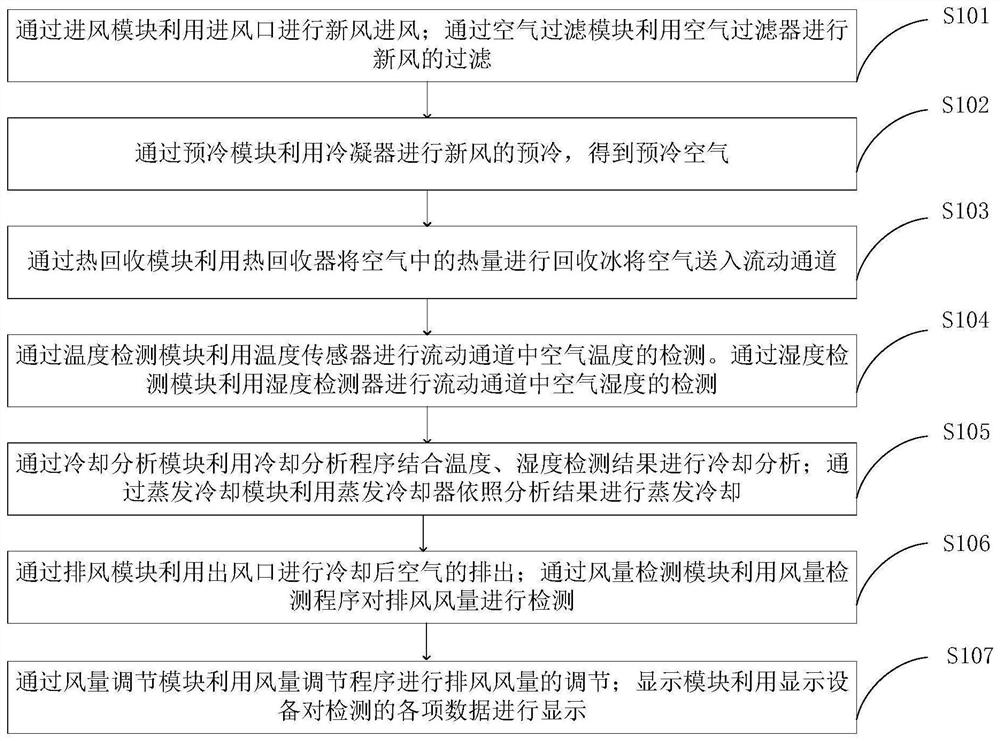

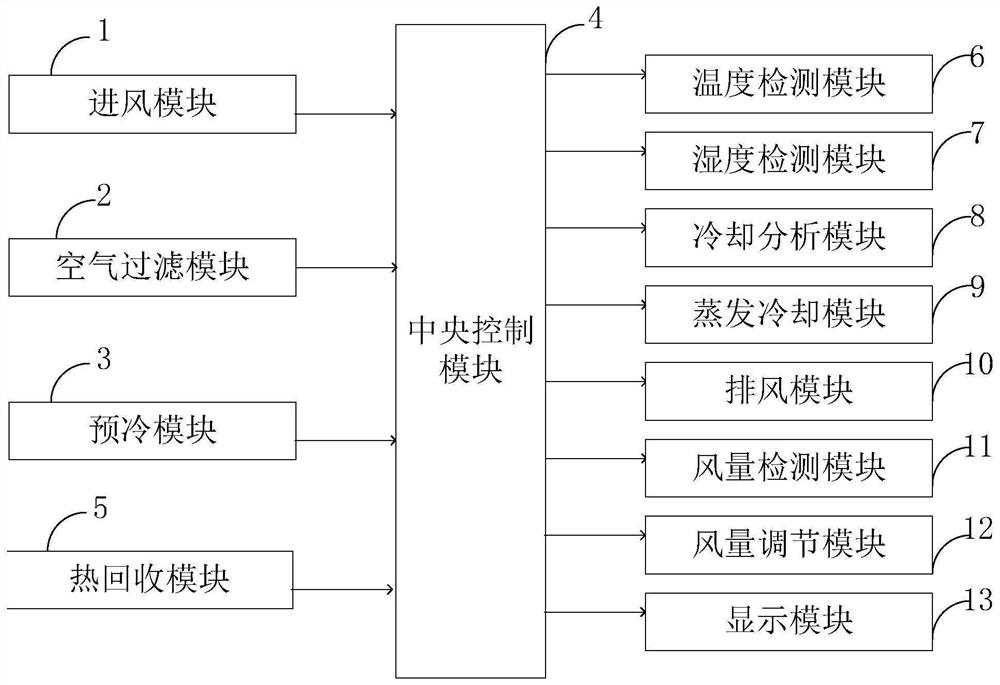

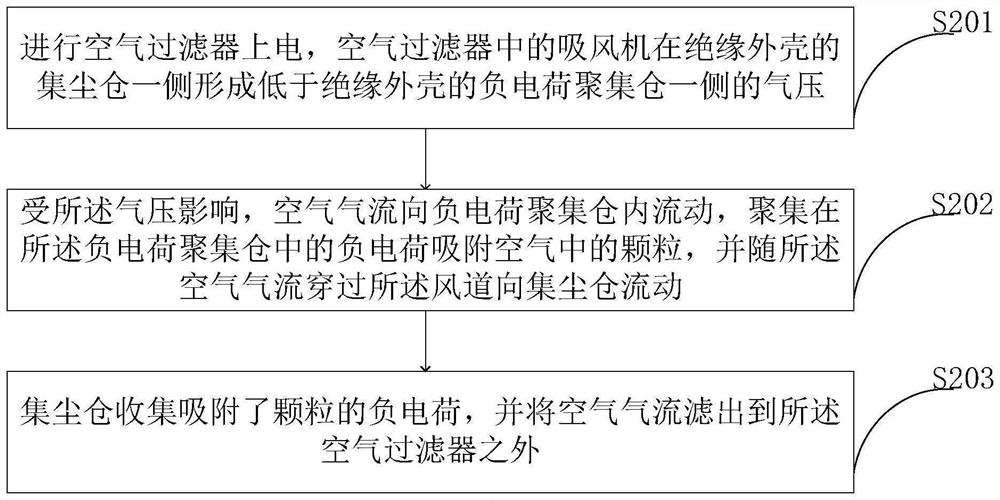

[0084] The energy efficiency intelligent control method of the indirect evaporative cooling unit provided by the embodiment of the present invention is as follows: figure 1 As shown, as a preferred embodiment, such as image 3 As shown, in step S101, the embodiment of the present invention uses an air filter module to filter fresh air through an air filter, including the following steps:

[0085] S201, the air filter is powered on, and the suction fan in the air filter forms an air pressure on the side of the dust collection bin of the insulating case that is lower than that on the side of the negative charge accumulation bin of the insulating case.

[0086] S202. Affected by the air pressure, the air flow flows into the negative charge accumulation chamber, and the negative charge accumulated in the negative charge accumulation chamber absorbs the particles in the air, and passes through the air duct with the air flow to the collection chamber. The dust bin flows.

[0087] ...

Embodiment 2

[0090] The energy efficiency intelligent control method of the indirect evaporative cooling unit provided by the embodiment of the present invention is as follows: figure 1 As shown, as a preferred embodiment, in step S102, the cooling analysis module provided by the embodiment of the present invention uses the cooling analysis program combined with the temperature and humidity detection results to perform cooling analysis, including: analyzing whether the state of the unit at this time meets the user's needs, the system Whether the energy efficiency ratio is the highest.

[0091] Such as Figure 4 As shown, the analysis provided by the embodiment of the present invention whether the current system status meets user needs, and whether the system energy efficiency ratio is the highest, specifically includes:

[0092] S301. Acquire collected air temperature and air humidity information.

[0093] S302, analyzing the energy efficiency point of the indirect evaporative cooling un...

Embodiment 3

[0096] The energy efficiency intelligent control method of the indirect evaporative cooling unit provided by the embodiment of the present invention is as follows: figure 1 As shown, as a preferred embodiment, the temperature detection module provided by the embodiment of the present invention uses a temperature sensor to detect the air temperature in the flow channel, including:

[0097] Use multiple temperature sensors to obtain multiple temperature signals of the air in the flow channel through the temperature detection module, and convert all the temperature signal values collected into AD values through the AD converter of the central control module; remove the maximum and minimum of multiple AD values Calculate the average value after the value, and use the calculated average value as the air temperature value in the flow channel;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com