Extrusion molding device for optical cable production line

A technology of production line and optical cable, which is applied in the field of extrusion device of optical cable production line, can solve the problems of low extrusion molding efficiency, blockage at the feed inlet, and affecting the feeding efficiency of the extruder, so as to achieve simple structure, avoid blockage, and manufacture low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

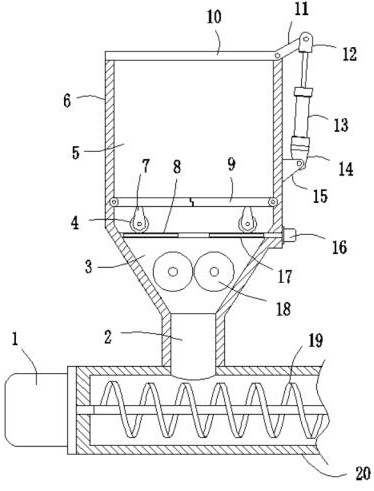

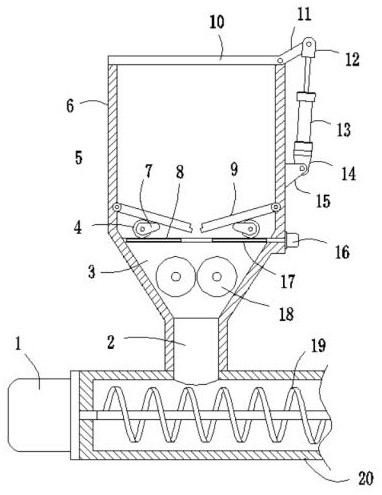

[0022]Such asFigure 1-2As shown, an extruding device for an optical cable production line includes a base 20 of an extruder. The base 20 is horizontally connected with an extrusion screw 19, and the extrusion screw 19 is installed on the base 20. The geared motor 1 on the upper drive rotates, the base 20 is provided with a feed port 2, and the upper port of the feed port 2 is connected with a feed bin 6 through it. The feed bin 6 has two symmetrical hinges along its axis. Two baffle plates 9, when the two baffle plates 9 are rotated to a horizontal state, the inside of the feeding bin 6 is divided into a storage cavity 5 and a crushing cavity 3 from top to bottom. The two baffle plates 9 is driven by the drive assembly to rotate in the opposite direction along the hinge joint with the inner wall of the feeding bin 6, so that the opposite ends of the two form a blanking space for the fiber optic cable raw materials to enter the crushing cavity 3, and the top of the feeding bin 6 is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com