Preparation method of 2-hydroxyethyl urea

A technology of hydroxyethyl urea and oxazolidinone, which is applied in the field of preparation of 2-hydroxyethyl urea, can solve the problems of reducing product quality, complicated reaction system and the like, and achieves the effect of high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

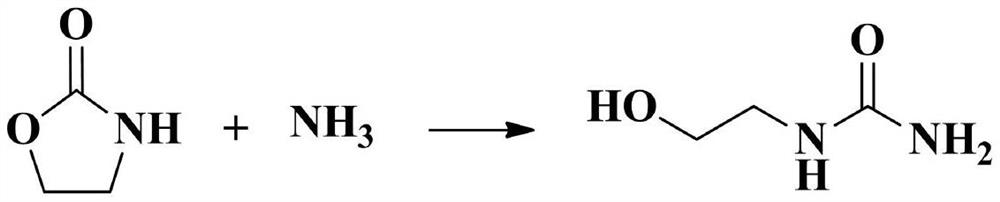

Method used

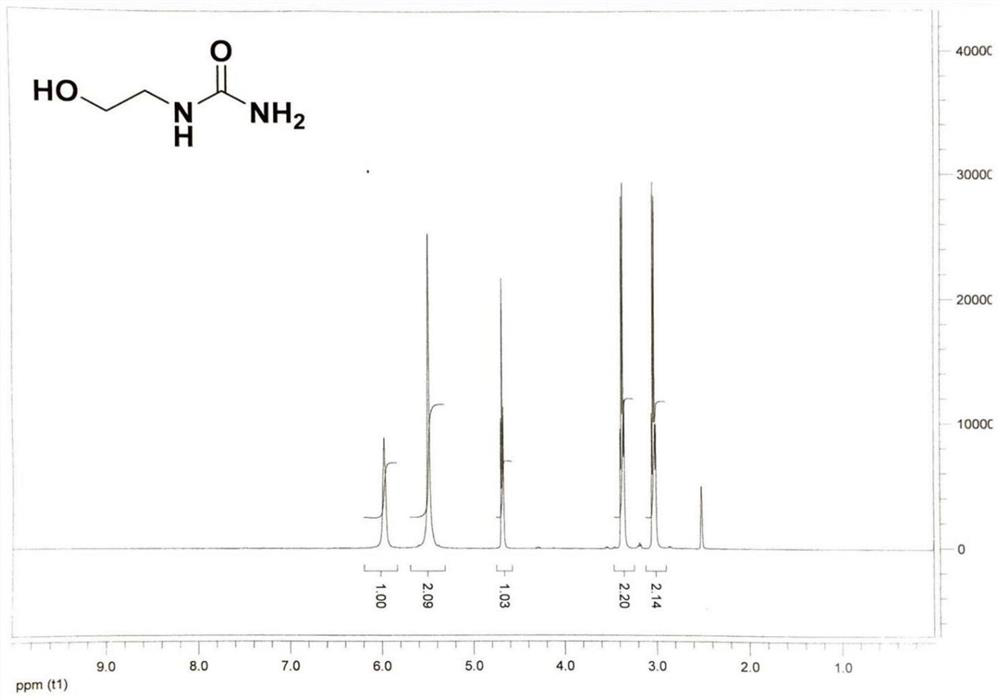

Image

Examples

Embodiment 1

[0023] Under the protection of nitrogen, first add 81.6g of ammonia water with a concentration of about 25%, 54g of water, 87.08g of 2-oxazolidinone, and 0.69g of catalyst potassium carbonate into the reactor. Insulated reaction for 4 hours, the reaction was completed, post-treatment, the reaction product 2-hydroxyethylurea 101.2g, yield 97.3% based on 2-oxazolidinone.

Embodiment 2

[0025] Under the protection of nitrogen, first add 95.2g of ammonia water with a concentration of about 25%, 54g of water, 87.08g of 2-oxazolidinone, and 1.38g of catalyst potassium carbonate into the reactor. Insulated reaction for 4 hours, the reaction was completed, post-treatment, the reaction product 2-hydroxyethyl urea 102.0g, yield 98.1% based on 2-oxazolidinone.

Embodiment 3

[0027] Under the protection of nitrogen, first add 81.6g of ammonia water with a concentration of about 25%, 54g of water, 87.08g of 2-oxazolidinone, and 0.69g of catalyst potassium carbonate into the reactor. Insulated reaction for 6 hours, the reaction was completed, post-treatment, the reaction product 2-hydroxyethyl urea 101.9g, yield 97.9% based on 2-oxazolidinone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com