On-ice anti-slip rubber and preparation method thereof

A rubber and anti-slip technology, which is applied in the field of rubber manufacturing, can solve problems such as easy to cause slipping injuries, unsatisfactory anti-slip performance, poor wear resistance and anti-slip effect on ice, etc., to improve wet skid resistance and improve durability Excellent folding resistance and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

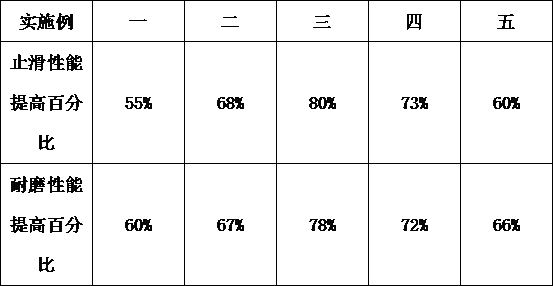

Examples

Embodiment 1

[0024] The present invention proposes a kind of anti-slip rubber on ice, comprising the following raw materials in parts by weight: 30 parts of natural rubber, 10 parts of nitrile rubber, 5 parts of butyl rubber, 35 parts of solution polystyrene butadiene rubber, 8 parts of white carbon black, 2 parts of anti-aging agent, 2 parts of white smoke active agent, 3 parts of carborundum, 6 parts of glass fiber, 2 parts of zinc oxide, 3 parts of sulfur, 3 parts of vulcanization accelerator;

[0025] Its preparation method comprises the following steps:

[0026] S1: Send natural rubber, nitrile rubber, butyl rubber, and solution-polymerized styrene-butadiene rubber to the open mill in sequence according to the formula ratio for thin pass plasticizing to obtain the standard rubber;

[0027] S2: Stir and mix the four standard glues in S1 with a low-speed mixer, the stirring speed is 200r / min, and the stirring time is 10min, to obtain a mixture;

[0028] S3: Add the mixture in S2 into a...

Embodiment 2

[0034] The present invention proposes a kind of anti-slip rubber on ice, comprising the following raw materials in parts by weight: 35 parts of natural rubber, 13 parts of nitrile rubber, 8 parts of butyl rubber, 38 parts of solution polystyrene butadiene rubber, 9 parts of white carbon black, 2.5 parts of anti-aging agent, 3 parts of white smoke active agent, 3.5 parts of carborundum, 7 parts of glass fiber, 3 parts of zinc oxide, 3.5 parts of sulfur, 3.5 parts of vulcanization accelerator;

[0035] Its preparation method comprises the following steps:

[0036] S1: Send natural rubber, nitrile rubber, butyl rubber, and solution-polymerized styrene-butadiene rubber to the open mill in sequence according to the formula ratio for thin pass plasticizing to obtain the standard rubber;

[0037] S2: Stir and mix the four standard glues in S1 with a low-speed mixer, the stirring speed is 200r / min, and the stirring time is 10min, to obtain a mixture;

[0038] S3: Add the mixture in S...

Embodiment 3

[0044] The present invention proposes a kind of anti-slip rubber on ice, comprising the following raw materials in parts by weight: 40 parts of natural rubber, 15 parts of nitrile rubber, 10 parts of butyl rubber, 40 parts of solution polystyrene butadiene rubber, 10 parts of white carbon black, 3 parts of anti-aging agent, 4 parts of white smoke active agent, 4 parts of carborundum, 8 parts of glass fiber, 4 parts of zinc oxide, 4 parts of sulfur, 4 parts of vulcanization accelerator;

[0045] Its preparation method comprises the following steps:

[0046] S1: Send natural rubber, nitrile rubber, butyl rubber, and solution-polymerized styrene-butadiene rubber to the open mill in sequence according to the formula ratio for thin pass plasticizing to obtain the standard rubber;

[0047]S2: Stir and mix the four standard glues in S1 with a low-speed mixer, the stirring speed is 200r / min, and the stirring time is 10min, to obtain a mixture;

[0048] S3: Add the mixture in S2 into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com