Constant-temperature adsorption skid-mounted platform and method for collecting lithium rubidium

A constant temperature and platform technology, applied in thermometers, measuring devices, engine lubrication, etc., can solve the problems of poor temperature control of the adsorption system, low efficiency of collecting lithium and rubidium, and improving energy consumption of collection, etc., to achieve rapid, uniform and stable temperature. Ease of movement and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

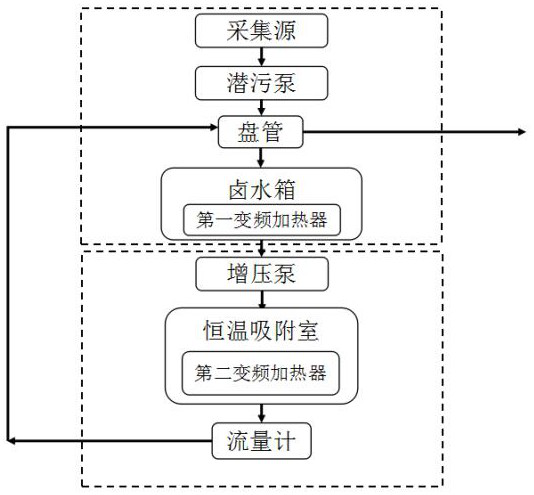

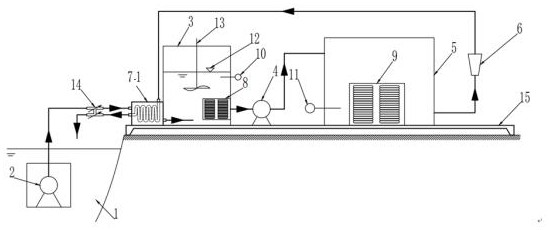

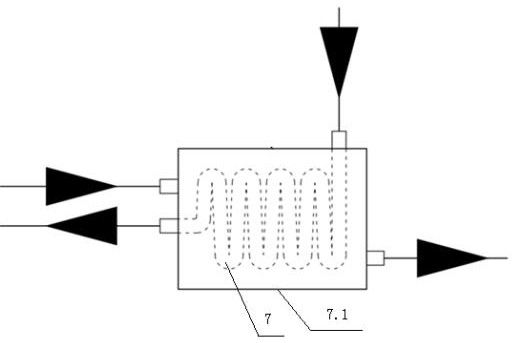

[0021] like figure 2 and image 3 As shown, a skid-mounted platform for constant temperature adsorption of lithium rubidium is collected, including: submersible sewage pump 2, heating box 7.1, brine tank 3, frequency conversion booster pump 4, constant temperature adsorption chamber 5 and skid-mounted platform 15, the described One end of the submersible sewage pump 2 is connected to the collection source 1, and the other is connected to the brine tank 3 through the heating box 7.1, and the brine tank 3 is connected to the constant temperature adsorption chamber 5 through the frequency conversion booster pump 4; One end of the pipe 7 extends out of the heating box 7.1, and the other end communicates with the constant temperature adsorption chamber 5. The heating box 7.1, the brine tank 3, the frequency conversion booster pump 4, and the constant temperature adsorption chamber 5 are all arranged on the skid-mounted platform 15.

[0022] The present invention arranges the heat...

Embodiment 2

[0024] On the basis of Example 1, such as figure 2 As shown, further, the brine tank 3 is provided with a first frequency conversion heater 8 , and the constant temperature adsorption chamber 5 is provided with a second frequency conversion heater 9 .

[0025] The brine tank 3 is also provided with a liquid level gauge 12 and an agitator 13 , the agitator 13 is vertically arranged and located above the first variable frequency heater 8 .

[0026] The submersible sewage pump 2 communicates with the heating tank 7.1 through the H-type dual-pipeline control valve 14, and at the same time, the coil pipe 7 is also connected with an external discharge pipeline through the H-type double-pipeline control valve 14. The H-type double-pipeline control valve 14 is convenient for equipment connection on the skid-mounted platform.

[0027] The brine tank 3 is provided with a first temperature sensor 10 , and the constant temperature adsorption chamber 5 is provided with a second temperatu...

Embodiment 3

[0035]On the basis of embodiment 2, the difference is: the method for the constant temperature adsorption of this collection lithium rubidium is: inject clear water in the described brine tank, the clear water in the described brine tank is in agitator, the first variable frequency heater, The temperature rises under the synergistic action of the first temperature sensor, and flows into the constant temperature adsorption chamber under the action of the frequency conversion booster pump, and continues to heat up under the joint action of the second frequency conversion heater and the second temperature sensor. It enters the coil and flows back into the brine tank through the H-type double-pipeline control valve. When the first temperature sensor and the second temperature sensor simultaneously display that the circulating temperature of the clean water reaches the operating temperature range set by the constant temperature adsorption, the H-type is closed. The double-pipeline c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com