Energy-saving constant-temperature adsorption equipment and method suitable for collecting lithium and rubidium

An adsorption equipment and constant temperature technology, which is applied in the field of adsorption equipment, energy-saving and constant temperature adsorption equipment, can solve the problems of high energy consumption, long production cycle, and low economic benefits, and achieve high collection efficiency, simple site requirements, and high temperature rise efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

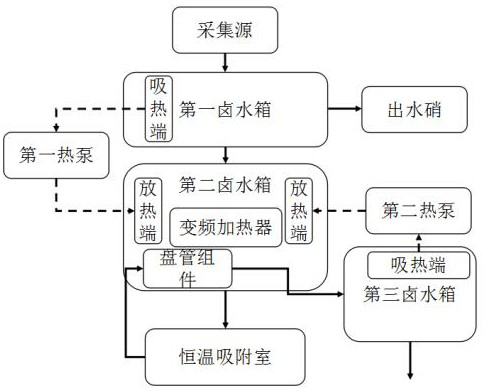

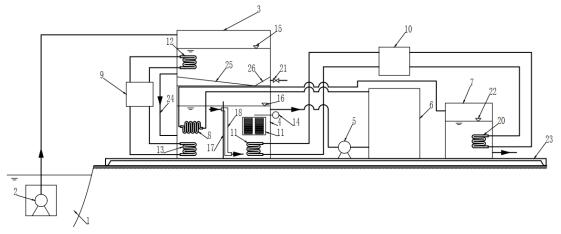

[0033] Such as figure 1 and figure 2 As shown, an energy-saving constant temperature adsorption equipment suitable for collecting lithium and rubidium includes a brine extraction system, a desalination and brine collection system, a constant temperature adsorption system, a tail liquid collection system and a heat circulation heating system. The inlet of the brine extraction system is connected with a The collection source 1, the outlet is connected with the first brine tank 3 of the desalination and brine collection system; the second brine tank 4 of the desalination and brine collection system is connected with the constant temperature adsorption system, and the constant temperature adsorption system is connected with the coil assembly 8 of the heat circulation heating system. The tail liquid collection system is connected, and the heat circulation heating system is respectively connected with the salt removal and brine collection system and the tail liquid collection syste...

Embodiment 2

[0036] On the basis of Example 1, such as figure 2 As shown, the brine extraction system is a submersible sewage pump 2.

[0037] The constant temperature adsorption system includes a booster pump 5 and a constant temperature adsorption chamber 6. The inlet of the constant temperature adsorption chamber 6 communicates with the right area of the second brine tank 4 of the desalination and brine collection system through the booster pump 5.

[0038] The tail liquid collection system includes a third brine tank 7 and a third liquid level gauge 22 , and the third liquid level gauge 22 is arranged on the third brine tank 7 . The brine in the third brine tank is regularly discharged.

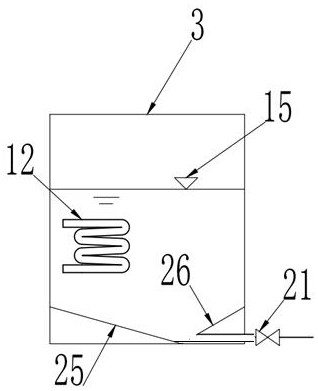

[0039] The described brine desalting and brine collection system comprises a first brine tank 3, a second brine tank 4, a partition 17 and an outlet nitrification valve 21,

[0040] The first brine tank 3 is arranged above the second brine tank 4, and the second brine tank 4 divides the second br...

Embodiment 3

[0054] On the basis of Example 2, the energy-saving constant temperature adsorption equipment suitable for collecting lithium rubidium also includes a carrier, which is a skid-mounted platform 23; the brine extraction system, desalination and brine collection system, constant temperature The adsorption system, tail liquid collection system and heat circulation heating system are all arranged on the skid-mounted platform 23 . The present invention performs operation and maintenance on the skid-mounted platform 23, and saves manual operation procedures as much as possible to realize short-distance control. In order to solve the problems of factory construction, high production cost, fixed site, high transportation cost and the need to configure multiple people for equipment operation and management.

[0055] Preferably, the temperature of the constant temperature adsorption system is controlled from 15°C to 35°C.

[0056] Preferably, the coil assembly 8 is made of a material wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com