Reverse design method, preparation method and application of recycled lightweight concrete

A technology of reverse design and lightweight concrete, which is applied in the field of construction technology and building materials, and can solve problems that affect the effective recycling and use of waste, unstable waste generation, and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

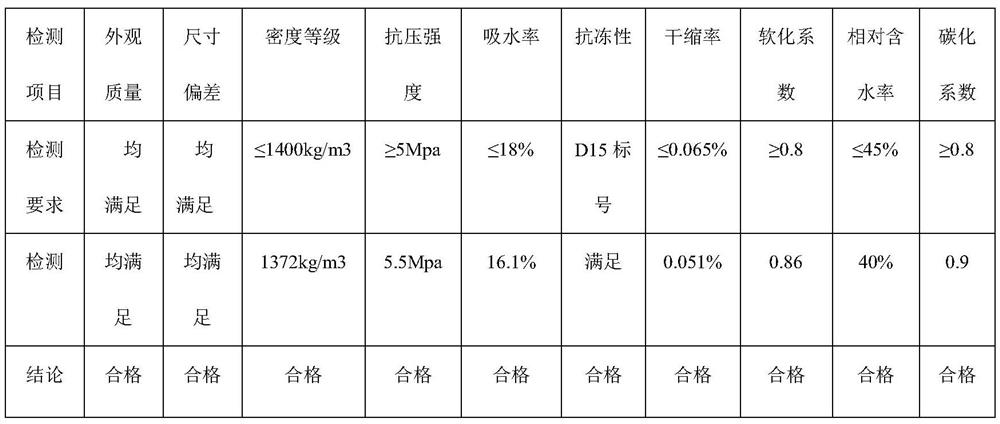

[0094] The production specification is 200×200×100 (mm) small hollow blocks of recycled light concrete, the hollow rate is 27%, and the density level is ≤1400kg / m 3 , intensity level MU5.

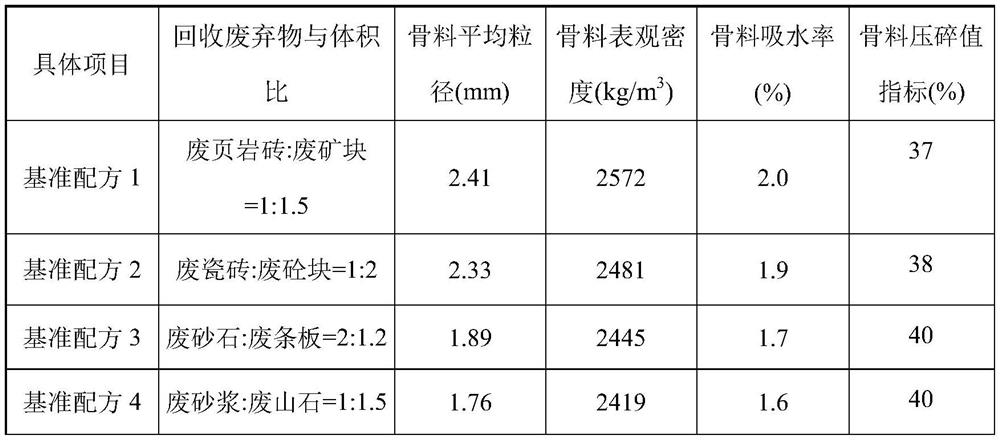

[0095] (1) Waste sorting and recycling methods and main tests:

[0096] ①Recycle light waste to prepare recycled light materials:

[0097] Light wastes include agricultural solid light wastes (residues of orange stalks include roots, stems, leaves, husks: examples such as corn stalks and leaves, corn cobs, rice husks, etc.); forestry solid light wastes (wood Processing sawdust particles and plant residues and urban garden trimmings, etc.), commercial solid light waste (foam, rubber, polymers, construction light solid waste ( Waste wood templates, waste plastic templates, waste ceramsite / water slag / polystyrene particles / foaming waste boards), and industrial solid light waste (distiller's grains, vinegar grains, etc.).

[0098] Recycling method: Separate one or more of the above-mentioned ...

Embodiment 2

[0208] In this example, waste drilling mud that is difficult to handle, bottom ash and fly ash produced by domestic waste incineration, vinegar grains, distiller's grains, etc. are used as raw materials in combination with other wastes, and the ratio design method and preparation method of Example 1 are used. Produce a variety of recycled lightweight concrete products.

[0209] The specific treatment plan for the selected raw materials: ① The pH value of the waste drilling mud is about 10, and the pH value of the vinegar residue is about 5. The pH value of the mixture after matching according to the following volume ratio is ≥ 6, which meets the concrete curing requirements; Density 2204kg / m 3 , with domestic waste incineration fly ash low apparent density 562kg / m 3 , the following mix ratios meet the limit requirements for controlling the apparent density in this product; ③The following mix ratios and mix ratios use the adsorption properties of recycled aggregates and light ...

Embodiment 3

[0222] Use the recycled raw materials prepared in Example 2 and other raw materials to produce recycled all-light concrete strips for building partition walls: the specification is 2800×600×100 mm.

[0223] (1) Prepare raw materials and test indicators, determine the benchmark mix ratio as required, and convert it into a production mix ratio.

[0224] (2) The basic formula of recycled all-light concrete slabs:

[0225] Table 5 Benchmark formula of recycled all-light concrete slabs

[0226]

[0227] In the table, the water consumption considers the water absorption rate of recycled aggregate and recycled light material; recycled aggregate and recycled light material do not contain powder; raw materials are dry materials. The composition of the recycled raw materials used in the corresponding benchmark formula is shown above.

[0228] (3) Use conventional concrete mixing equipment to make recycled all-light concrete according to the 3-stage feeding continuous mixing method,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com