Rubber composition

A technology of rubber composition and rubber, which is applied in the field of rubber composition, can solve the problems of low heat generation, and achieve the effect of low heat generation and excellent dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0190] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to this.

[0191] 〔Synthesis example〕

[0192] Comparative modified IR and specific modified IR 1 to 5 were synthesized as described below.

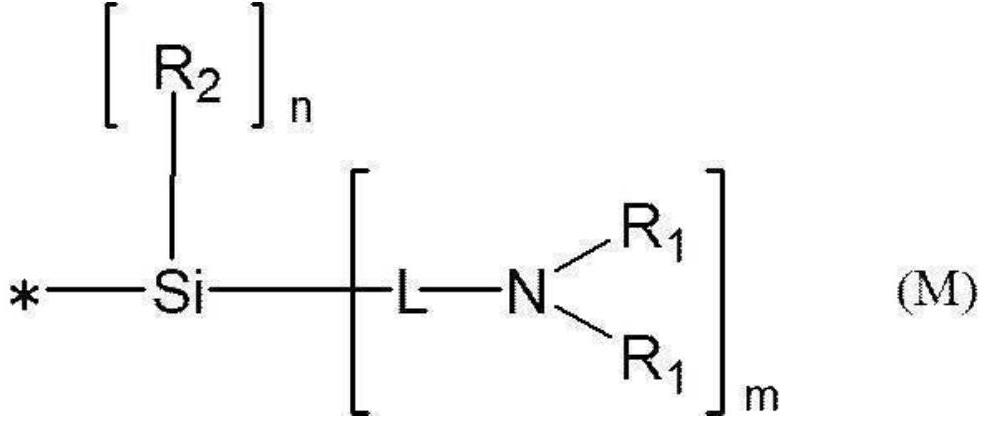

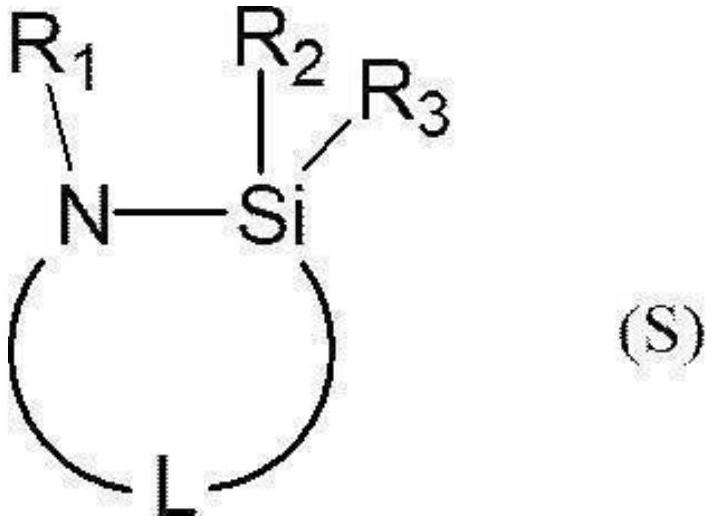

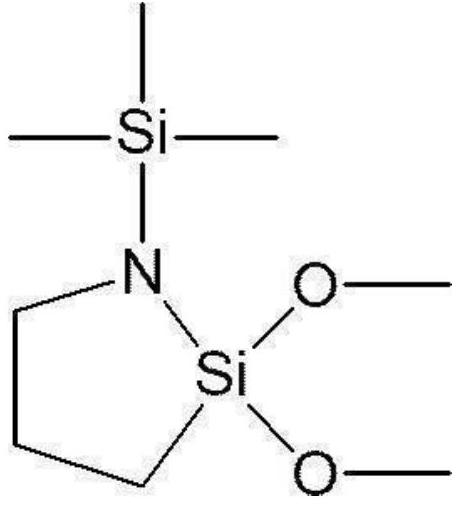

[0193] Here, the specific modified IRs 1 to 5 all have a functional group represented by the formula (m1) described later corresponding to the specific functional group at the terminal, and have a viscosity of 2,000 Pa·s or less, so they correspond to the above-mentioned "specific modified IR". On the other hand, the comparative modified IR has a specific functional group at the terminal, but its viscosity exceeds 2,000 Pa·s, so it does not correspond to the above-mentioned "specific modified IR".

[0194]

[0195] Add n-BuLi (manufactured by Kanto Chemical Industry: 1.60mol / L (hexane solution), 51mL, 82mmol) to a mixed solution of isoprene (708g, 10.4mmol) in cyclohexane (4.0kg), at 50°C Stirring was continued for 6 hours. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap