Adjustable clamping device for safety door frame machining

A clamping device and adjustable technology, which is applied in the field of adjustable clamping devices for safety door frame processing, can solve problems such as practical inconvenience, precision error, and single standard clamping form, so as to improve practicability, improve precision, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

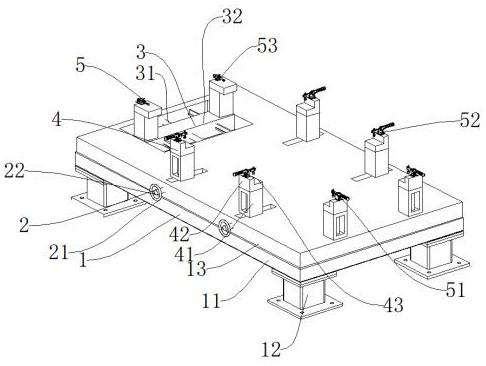

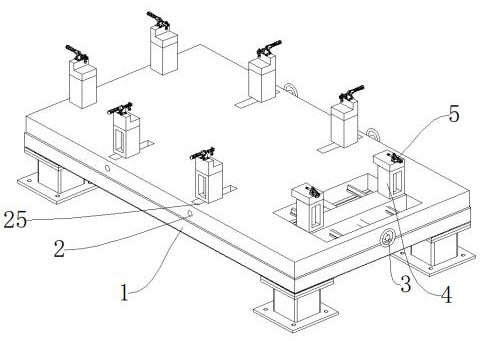

[0044]Such asFigure 1-Figure 6As shown, an adjustable clamping device for processing a safety door frame includes a supporting mechanism 1 for supporting, a clamping mechanism 5 for clamping, and an anti-loosening mechanism 7 for preventing loosening. The supporting mechanism 1 is installed with Horizontal adjustment mechanism 2, one side of the horizontal adjustment mechanism 2 is provided with a longitudinal adjustment mechanism 3, the upper ends of the horizontal adjustment mechanism 2 and the longitudinal adjustment mechanism 3 are both installed with a height adjustment mechanism 4, the upper end of the height adjustment mechanism 4 is installed with a clamping mechanism 5, horizontal adjustment An anti-loosening mechanism 7 is provided between the mechanism 2 and the longitudinal adjustment mechanism 3, and a linkage mechanism 6 is connected to the horizontal adjustment mechanism 2;

[0045]The supporting mechanism 1 includes a supporting base 11, a supporting column 12, and a ba...

Embodiment 2

[0053]Such asFigure 7 The difference between this embodiment and embodiment 1 is:

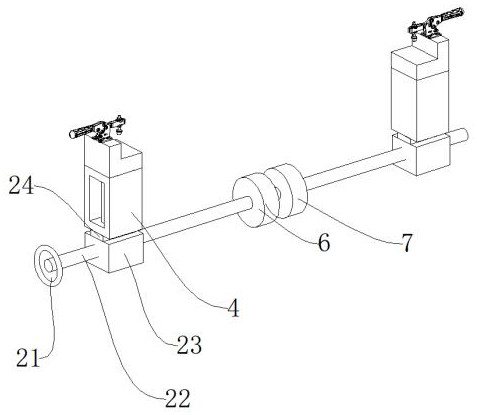

[0054]The linkage mechanism 6 includes a linkage bevel gear 611, a transmission bevel gear 612, and a connecting rod 613. The two linkage bevel gears 611 are respectively mounted on the lateral adjustment screw 22. One side of the linkage bevel gear 611 is connected with a transmission bevel gear 612. The gears 612 are connected by a connecting rod 613. When synchronous rotation adjustment of the lateral adjustment screw 22 is required, the linkage bevel gear 611, the transmission bevel gear 612, and the connecting rod 613 cooperate to make the two lateral adjustment screws 22 rotate synchronously.

[0055]Working principle: According to the specifications of the door frame, adjust the position of the horizontal adjustment slider 23 and the longitudinal adjustment slider 32, so that the second clamp 52 and the ejector clamp 53 can clamp the door frame parts, and then according to the different parts of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com