Economic and environment-friendly polyurethane thermal insulation foam and preparation method thereof

A polyurethane, environmentally friendly technology, applied in the field of polyurethane, can solve the problems of expensive foaming agent, unfavorable product development and application, etc., and achieve the effects of excellent foam dimensional stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] In the second aspect, the present application provides a method for preparing the above-mentioned economical and environment-friendly polyurethane thermal insulation foam, which is characterized in that the method comprises the following steps: combining the polyether polyol and the isocyanate under high pressure Mix in a foam machine, and obtain the polyurethane thermal insulation foam after foaming.

[0057] In an embodiment of the second aspect, the foaming temperature is room temperature, and the injection flow rate of the combined polyether polyol and the isocyanate is 30 g / s during foaming.

[0058] On the basis of not violating common knowledge in the field, the above-mentioned preferred conditions can be combined arbitrarily to obtain preferred examples of the present invention.

[0059] The reagents and raw materials used in the present invention are all commercially available.

[0060] Percentages in the present invention are the mass percentages of each comp...

Embodiment 1-5

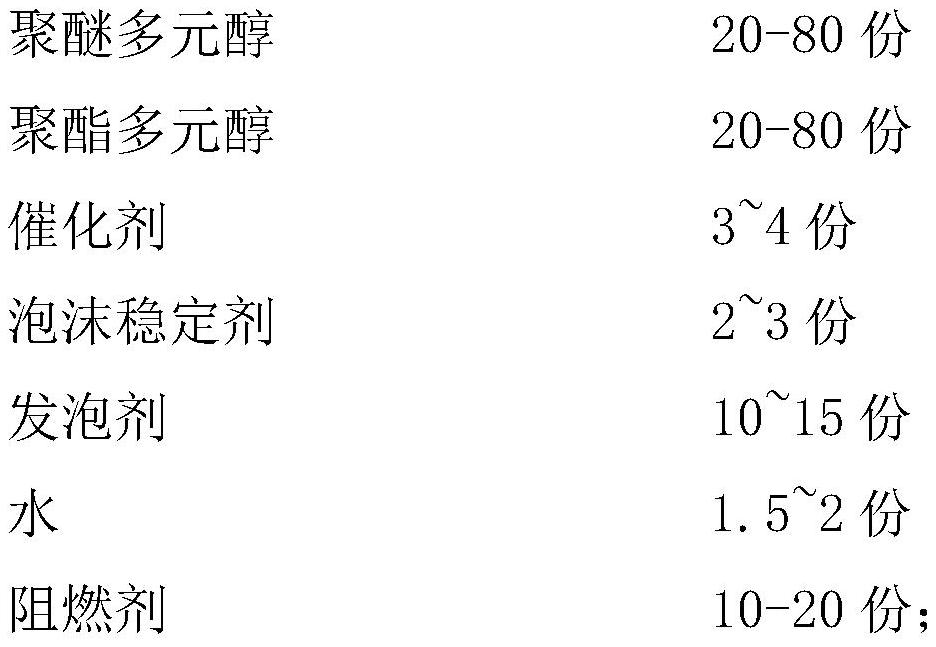

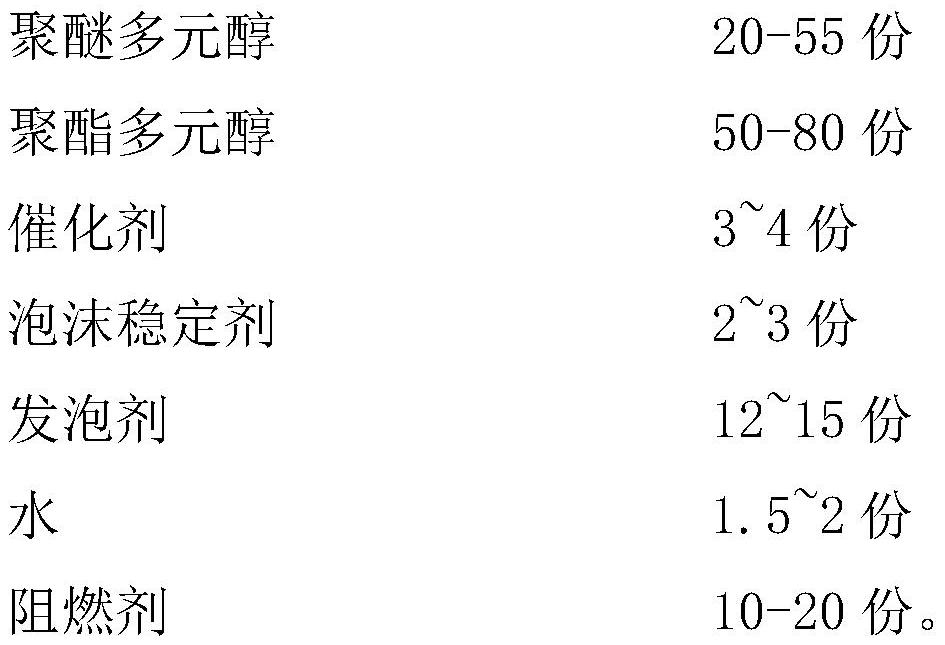

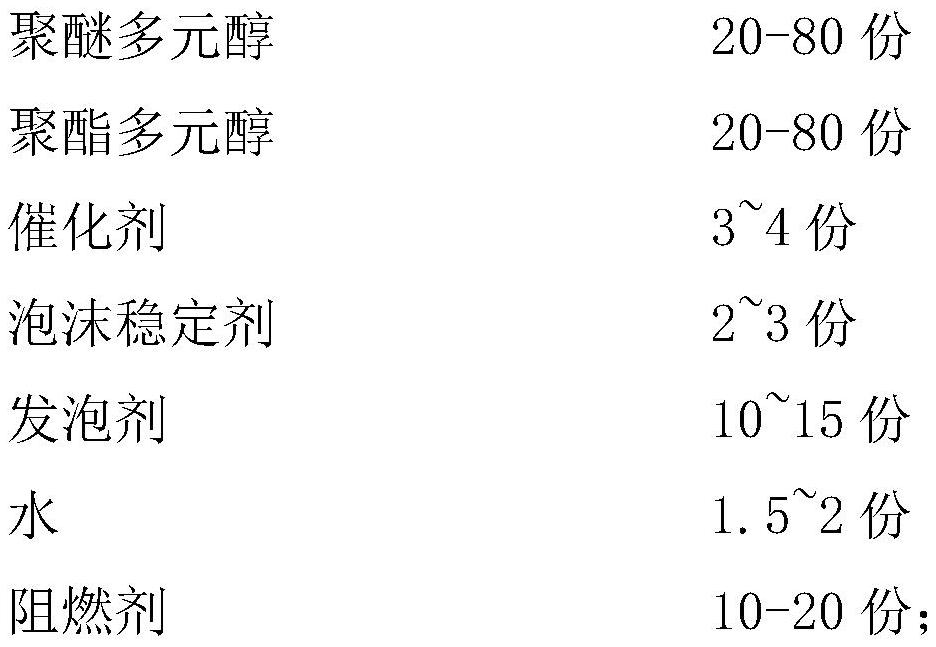

[0080] The types and amounts of raw materials for the combined polyether polyols of Examples 1-5 are shown in Table 1 below.

[0081] Table 1 Components and contents of the combined polyether polyols of Examples 1-5.

[0082]

[0083]

[0084] The steps of preparing combined polyether polyols include: weighing polyether polyols, polyester polyols, catalysts, silicone oil, water, flame retardants, and foaming agents in a reaction kettle, and stirring evenly to obtain combined polyether polyols. Polyol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com