Unloading system and unloading method of easy-to-vaporize liquid tank car

A technology for vaporizing liquids and tank cars, which is applied in the field of unloading systems for easy-to-vaporize liquid tank cars. It can solve problems such as low efficiency, pulse vibration of transmission pipelines, and impact on service life, and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

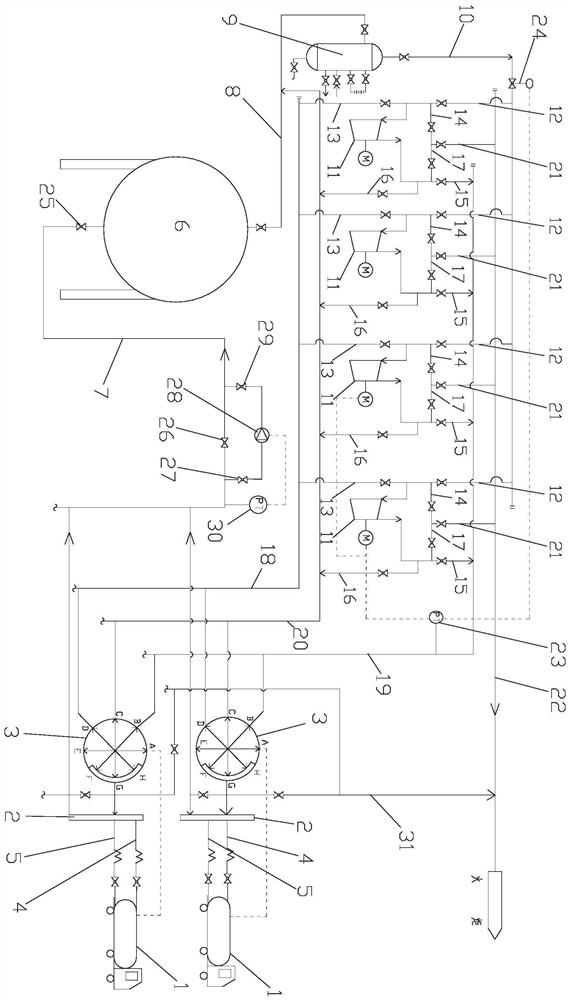

[0029] like figure 1 As shown, a tank car unloading system for easily vaporized liquid includes multiple tank car units, a liquid storage tank 6, four compressors 11, a vapor-liquid separation tank 9, a punching line 19, an equalizing line 20, and a pumping line 18. Go to the torch line 22.

[0030] Each tank car unit includes a tank car 1, an unloading crane position 2 and a four-position four-way valve 3. The unloading crane position 2 is connected to the gas phase interface of the tank car 1 through the gas phase crane pipe 4, and the unloading crane position 2 is connected to the gas phase interface of the tank car 1 through the liquid phase The crane pipe 5 is connected to the liquid phase interface of the tank car 1. The four-position four-way valve 3 includes an open position of B-F, an open position of C-G, an open position of D-H and a closed position of A-E. The four-position four-way valve H port, G port, F Both ports are connected to the unloading crane position 2...

Embodiment 2

[0040] like figure 1 Shown, a kind of unloading method of easily vaporized liquid tank car unloading system comprises the following steps:

[0041] Step 1, firstly purging and cleaning the pipeline, valve and vapor-liquid separation tank 9, filling the gas phase of the liquid with other pipelines except the liquid phase pipeline 7 by venting or replacing, so that the liquid phase is filled with the liquid phase pipeline 7;

[0042] Open each valve on the gas phase crane tube 4, the liquid phase crane tube 5, the first gas phase line 8 and the second gas phase line 10, open the liquid phase pipeline 7 first valve 25 and the second valve 26, and the first remote pressure transmission The valve of the first branch line 12 at the inlet of the compressor 11 electrically connected to the device 23 is opened, the valve of the third branch line 15 at the outlet is opened, and the remaining valves are closed;

[0043] Step 2: start the compressor 11 electrically connected to the first...

Embodiment 3

[0051] like figure 1 Shown, the unloading method of a kind of easily vaporized liquid tank car unloading system, differs from embodiment 2 in that:

[0052] Step 1, firstly purging and cleaning the pipeline, valve and vapor-liquid separation tank 9, filling the gas phase of the liquid with other pipelines except the liquid phase pipeline 7 by venting or replacing, so that the liquid phase is filled with the liquid phase pipeline 7;

[0053] When the material in the tank car 1 needs to be transported over a long distance, open the valves on the gas phase crane pipe 4, the liquid phase crane pipe 5, the first gas phase line 8 and the second gas phase line 10, and open the first valve 25 of the liquid phase pipeline 7, The third valve 27, the pipeline pump 28 and the fourth valve 29 open the valve of the first branch line 12 at the inlet of the compressor 11 electrically connected to the first remote pressure transmitter 23, open the valve of the third branch line 15 at the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com