Electronic detonator front-end control circuit

A technology for controlling circuits and electronic detonators, which is applied in weapon accessories, fuzes, offensive equipment, etc., can solve the problems of endangering personal and property safety, electronic detonator detonation error, signal distortion, etc., and achieve the effect of eliminating the danger of failure and speeding up the wiring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

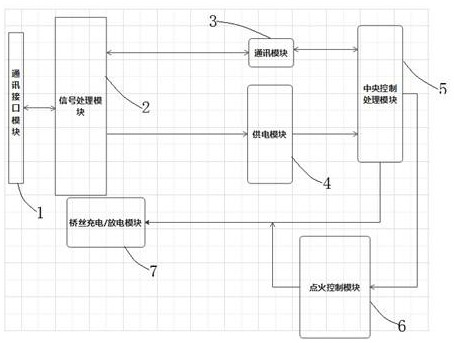

[0030] Example 1 please refer to figure 1 An embodiment shown is a front-end control circuit of an electronic detonator, including a communication interface module 1, a signal processing module 2, a communication module 3, a power supply module 4, a central control processing module 5, an ignition control module 6 and bridge wire charging / discharging Module 7, of which:

[0031] One end of the communication interface module 1 is connected to an external detonator, and the other end is connected to one end of the signal processing module 2, and the communication interface module 1 realizes communication and current flow between the above-mentioned other modules and the external detonator;

[0032] The other end of the signal processing module 2 is respectively connected to one end of the communication module 3 and the power supply module 4, and the communication interface module 1 prevents the current with a frequency between 50MHz-100 MHz from interfering with the communicatio...

Embodiment 2

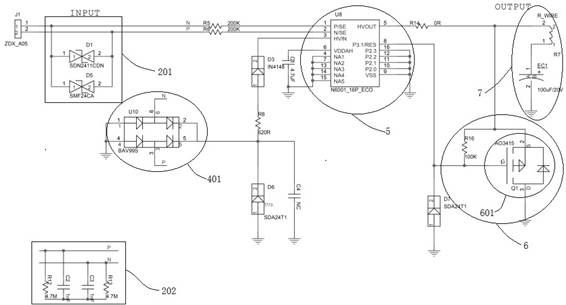

[0039] On the basis of the above-mentioned embodiment 1, please refer to the embodiment 2 figure 2 In one embodiment shown, the signal processing module 2 includes an ESD circuit 201 and an EMI circuit 202, and the ESD circuit and the EMI circuit are respectively connected in parallel with the P / N lines in the circuit.

[0040] Preferably, the EMI circuit 202 includes a capacitance group of two capacitive elements connected in series, a resistance group of two series resistance elements and a P / N line connected to the control circuit, and the capacitance group is connected in parallel to the P / N line , the resistance group is connected in parallel to the P / N line, wherein:

[0041] The resistive element is 4.7M ohms, and the capacitive element is 1nF.

[0042] Preferably, the ESD circuit 201 includes an ESD electrostatic impedance device D1, an ESD electrostatic impedance device D2 and a P / N line connected to the control circuit, and the ESD electrostatic impedance device D1...

Embodiment 3

[0046] On the basis of the above embodiments, Embodiment 3 shows an embodiment, the power supply module 4 is provided with a rectification circuit 401, the rectification circuit includes four rectification diodes, and every two rectification diodes are connected in series to form two groups The rectifier bridge, the two sets of rectifier bridges form a full bridge circuit.

[0047] The power supply module 4 is provided with a rectification circuit 401. The rectification circuit includes four rectification diodes. Every two rectification diodes are connected in series to form two sets of rectification bridges. The two sets of rectification bridges form a full bridge circuit. This circuit is a rectification circuit that converts alternating current into stable Direct current, when communicating with the external detonator, the detonator can connect the two communication wires regardless of the front and back, and can connect them arbitrarily, which speeds up the wiring efficiency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com