Surface defect detection system and method

A defect detection and detection platform technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of easily causing safety risks, labor consumption, and time-consuming handling processes, and achieve the effect of reducing production costs and safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

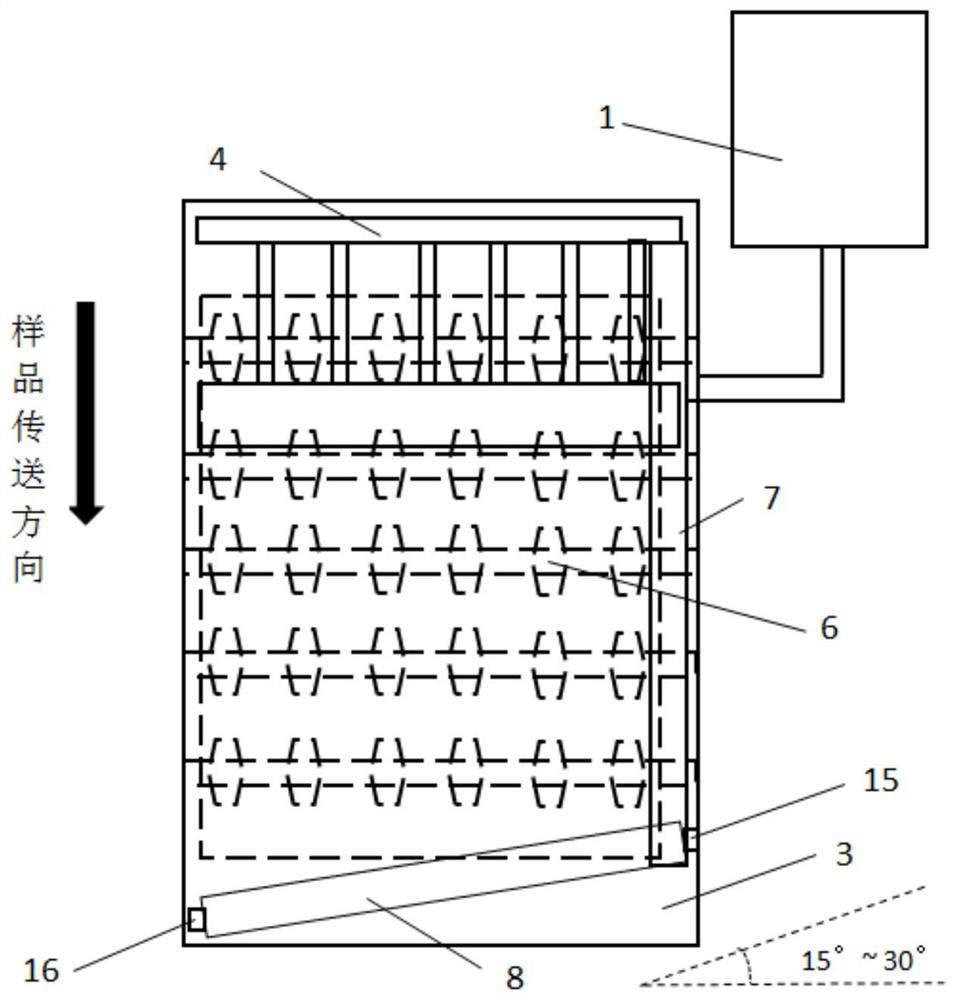

[0032] In this embodiment, the sample conveying direction is perpendicular to the vertical direction, and the sample width direction is perpendicular to the sample conveying direction and the vertical direction.

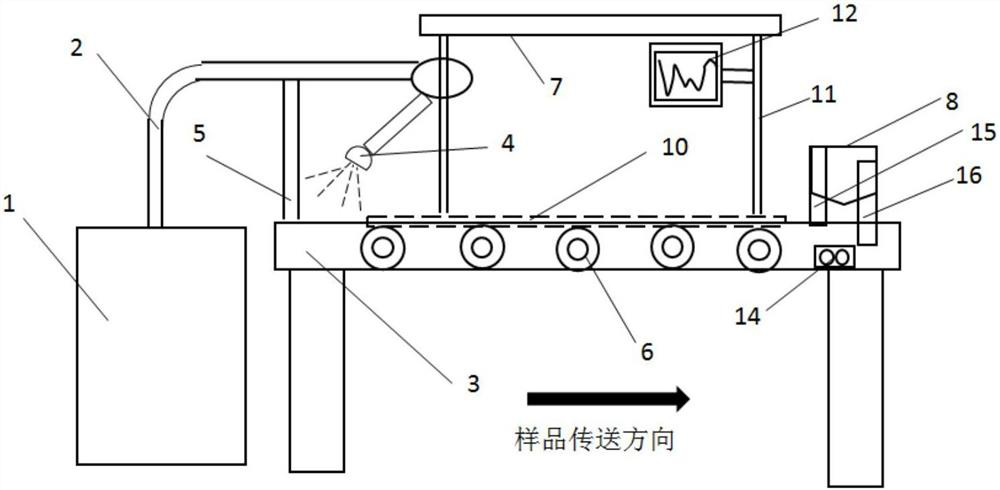

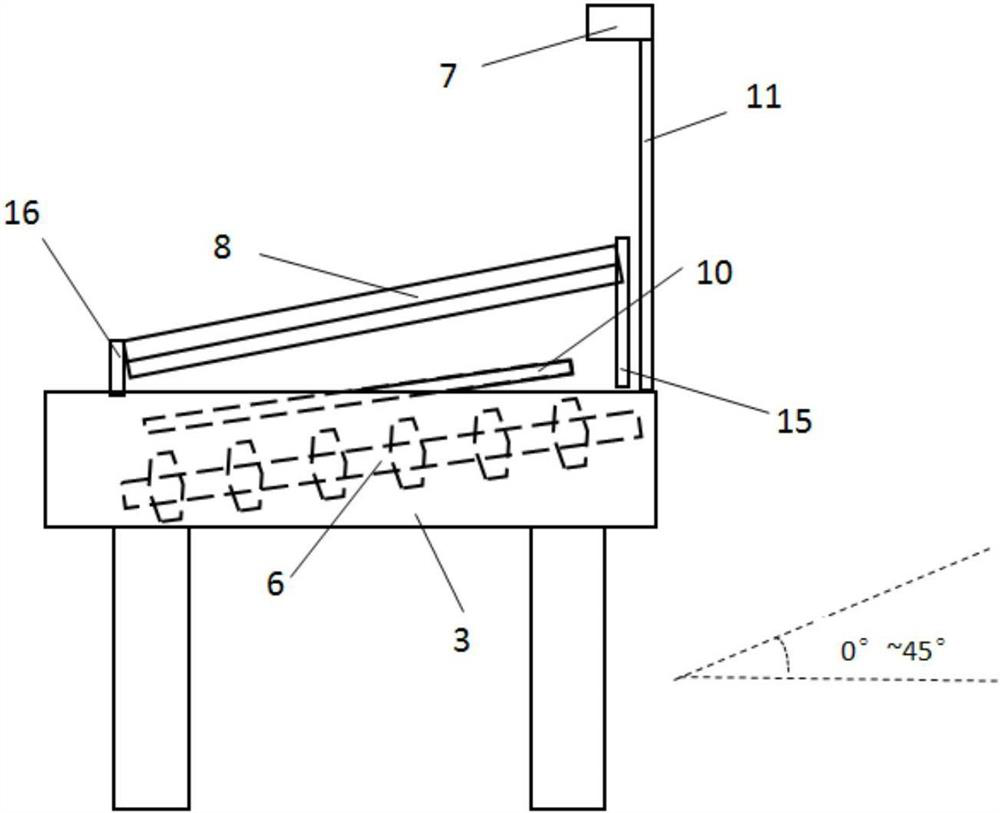

[0033] Such as Figure 1 to Figure 3 As shown, this embodiment provides a surface defect detection system, including: a detection platform 3, the inlet end of which is used to connect with the output line of the previous process equipment, and its outlet end is used to connect with the input line of the next process equipment; The transmission roller group 6 is installed on the platform 3, and is used for conveying the sample 10; The steam spray part, it is positioned at the entrance end of the detection platform 3, is used for spraying the steam to the sample 10 to form a mist film on the surface of the sample 10; the light source part, It is used to provide irr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com